New Line of Tapered Carbide End Mills for NPT/NPTF Pipe Threads is Available

The solution from EMUGE-FRANKEN USA saves costs and eliminates the need for multiple sizes of taper reamers.

Posted: June 28, 2022

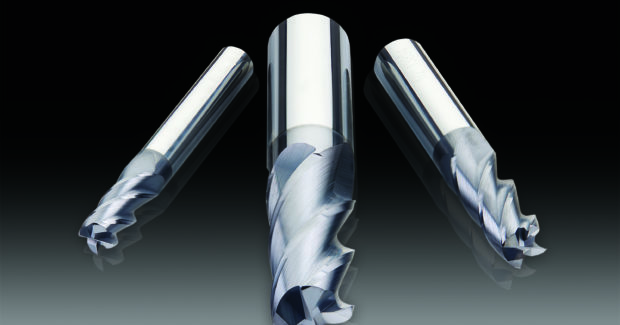

EMUGE-FRANKEN USA, a leading manufacturer of high-performance taps, thread mills, end mills, drills, and other rotary tools, recently introduced a new line of 1:16 Tapered Solid Carbide End Mills designed to prepare a tapered core hole prior to finish tapping or thread milling NPT/ NPTF/ BSPT pipe threads. The new cutters feature an innovative design that reduces the number of tools required for hole preparation over a large range of pipe thread sizes, and they extend the tool life of expensive taps and thread mills.

“Uniquely designed with the proper 1:16 taper angle ground into the conical form for milling the minor diameter of taper pipe threads prior to tapping or thread milling, these new tools provide an enormous advantage over HSS taper reamers, offering substantial time and cost savings,” said Dylan Bowles, Applications Support Specialist at EMUGE-FRANKEN USA. “And these tools do not require a large or 5-Axis machine tool, as smaller 3-axis machines can handle larger threading applications.”

Only three EMUGE-FRANKEN Tapered tool sizes are required to handle a full range of hole sizes from 1/4″ up to 4″, instead of having to purchase an individual taper reamer for each pipe thread size. They also provide a highly efficient and secure method for optimizing thread milling strategies which incorporate the use of partial-profile insert technology.

EMUGE-FRANKEN 1:16 Tapered Carbide End Mills work well in a full range of materials from aluminum, carbon steels, stainless steels, and exotic nickel alloys. They are made of a premium micro-grain carbide substrate with TIALN-T21 coating which resists heat, edge wear and chipping. Corner radii further prevent wear or chipping while prolonging tool life. Tools are four-fluted, feature standard US length and straight inch shank (h6), and are available in three sizes: 3/8″, 1/2″ and 3/4″.

EMUGE-FRANKEN USA offers users additional information and programming support for the 1:16 Tapered Carbide End Mills at https://info.emuge.com/nptendmill.

Subscribe to learn the latest in manufacturing.