IMTS 2022: Gear Generation

View everything gear-related and learn about traditional applications such as auto, as well as emerging opportunities in the alternative energy and wind power sectors.

Posted: July 19, 2022

Power Skiving and Gear Shaping with Mytec HYDRACLAMP

Skiving has been around for a long time, but recent advances in technology have improved the speed and effectiveness of this gear-making process making it a more viable manufacturing option for gear producers. It has long been recognized that skiving would be a much more productive process than shaping for cutting many internal gears. Euro-Tech Corp. (Menomonee Falls, WI) will demonstrate its Mytec HYDRACLAMP clamping tools, which are robust and rigid enough to minimize vibrations caused by the high spindle rpms and significant cutting forces generated by the new “Power Skiving” process. Euro-Tech Corp. will be in Booth W-432272.

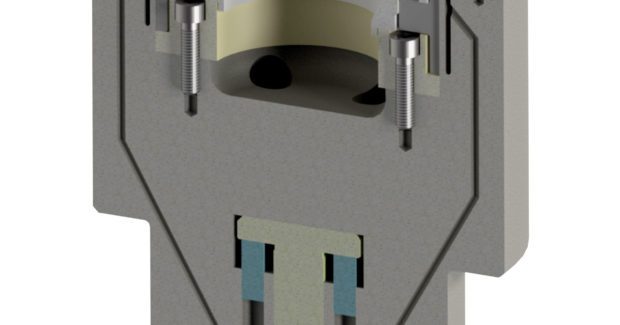

Today’s demands also include clamping very thin parts for the robotic gear boxes (flex spline gear box). Mytec HYDRACLAMP clamping tools are designed to clamp components the entire length of the clamping area. If the component is irregularly shaped, we clamp around it to achieve the highest accuracy. View the image as an example of a clamping situation with such a component used in the robotic gear box. Note the external shape is irregular and the clamping area is short. We designed a hydraulic chuck in combination with a changeable back stop and slotted collet. This gives the customer options to clamp different diameters and components with one hydraulic chuck. This hydraulic chuck is used to machine the spline in the “Gear Shaping” process on a Liebherr machine.

Mytec HYDRACLAMP continues to work closely with different machine producers to develop the perfect clamping solutions providing the highest runout accuracy, successive repeatability, and high clamping force applications. Euro-Tech Corporation is the exclusive North American distributor of the Mytec HYDRACLAMP product line.

Booth W-432272

New Gear Hobbing Machine to Make Debut at IMTS

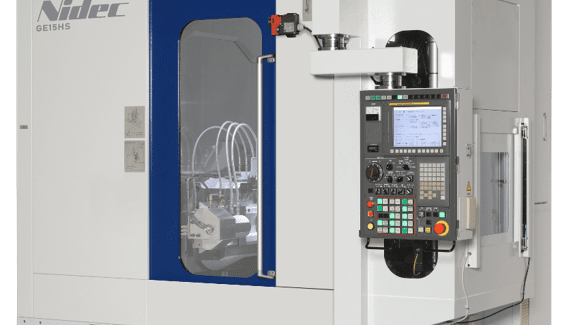

Supply chain issues are driving more companies to bring manufacturing back in-house. Parallel to this trend in automotive manufacturing is the rise of electric vehicles and increasing automation. Nidec Machine Tool America LLC (Wixom, MI), responding to the needs of the industry, is debuting the new GE15HS gear hobbing machine at IMTS in Booth N-237036. Emphasizing high speed, precision and efficiency, the new machine produces gears for electric and hybrid cars, as well as for robotic and automation applications.

The GE15HS model is designed for gears with a maximum diameter of 150 mm, widely used in automobiles and motorcycles. The high-speed, high-torque direct-drive motor1 for the main cutting spindle provides a maximum spindle speed of 6,000 min-1 2 — three times faster than previous models. The high-efficiency spindle holding the workpiece uses a special table that provides high rigidity and high-speed rotation to handle the necessary thrust load3 for high efficiency machining. Cutting gears with Nidec super-hard cutting tools yields a surface roughness of less than Ra0.44; on par with gear grinding. Scott Knoy, Nidec Machine Tool America’s Vice President of Sales said: “The GE15HS provides process efficiency, eliminating the finishing process of shaving prior to heat treatment, thereby improving productivity and reducing processing cost.” A larger machine, the GE25HS, is also available.

Used in combination with Nidec Machine Tool’s new materials and coatings for cutting tools, the GE15HS model provides stable mass production with a maximum cutting speed of 1,500m/min.

More than 2,800 Nidec GE Series hobbing machines have been delivered and installed since the product launched in 2004.

The Nidec booth will also feature the ZI20A-G Generating Internal Gear Grinder. Hard finishing of internal ring gears in mass production is the final frontier for automotive and truck transmission applications. For quiet, smoothly meshing internal ring gears, the ZI20A-G utilizes patented technology for threaded wheel grinding. This breakthrough process delivers fast and very cost-effective production of internal ring gears for planetary gearsets.

www.nidec-machinetoolamerica.com

Booth N-237036

Notes

1: Direct-drive mechanism motors utilize the torque coming from a motor without passing through a gear box or other mechanism in order to control driving loss due to friction and reduce wear on parts.

2: The “min-1” notation is a unit expressing the number of turns in one minute, synonymous with “revolutions/rotations per minute” (rpm).

3: Thrust load is the force applied to the shaft in a horizontal (parallel) direction (the axial direction of the rotor).

4: In-house machining result with GE15S (Workpiece data: Module 1.6 mm; No. of teeth 19; helix angle: 24°; face width: 24 mm).

Subscribe to learn the latest in manufacturing.