The Freedom to Innovate: TRUMPF Inc. Assists Customers in Realizing Their Greatest Projects

The embodiment of TRUMPF is the ability to integrate its high-quality machine tools with its high-quality lasers to build machines that enhance their customers’ competitiveness.

Posted: July 19, 2022

SUPPLIER PROFILE

At last count there were more than 120 products in the machine tool division of TRUMPF’s portfolio. The product lineup consists of a broad spectrum of products that focus on supporting a variety of metal fabrication processes. This diverse portfolio of technologies includes affordable basic machinery as well as highly integrated and automated Smart Factory solutions.

TRUMPF GmbH + Co. KG. is based near Stuttgart, Germany, and its North American subsidiary is TRUMPF Inc., which is located in Farmington, Conn. TRUMPF is a technology and market leader in versatile machine tools for sheet metal processing and in the field of industrial lasers.

“The essence of TRUMPF is the marriage of our machine tools with our lasers,” said Burke Doar, executive vice president, TRUMPF Inc. He was recently promoted and oversees substantial aspects of the company’s North American sales and marketing from the Farmington location. “We build both the machine tools and lasers and we don’t rely on other suppliers to support us with those two fundamental products and technologies.” The company builds machinery which they believe enhances a customer’s ability to perform at a higher level and compete globally, while minding the bottom line.

“In some cases, we don’t have to integrate them [lasers],” Doar said. “The lasers are sold as independent components that are used and integrated into other systems.” Doar noted that TRUMPF has capable competitors that build machine tools or lasers but there are not many that build both. “And that is one of the unique attributes of TRUMPF that is relative to the market.”

The metal fabrication business has experienced significant changes during the years with the implementation of automation in the processes, but in some ways, the principles remain the same. “We are in the business of providing technology that enables different companies to manufacture their products at the lowest cost per part,” Doar said.

There are three fundamental aspects of TRUMPF’s business that are essential to its customers:

- Development of machine tools, automation and software that are both productive and efficient.

- Fabrication technology that is focused on flexibility, allowing rapid change-over between jobs and the agility to meet changing demands.

- Most importantly, from the smallest shops to the largest factories, customers look to TRUMPF for meaningful innovations that enhance their competitiveness.

Doar added the fundamental imperative for companies when purchasing machine tools and lasers to compete is similar to what it was a little more than 20 years ago when he began his career with TRUMPF. The one notable change is the use of automation “in what we call high variation sheet metal manufacturing,” Doar said. So, it’s the capability to implement automation techniques to create a series of parts in small quantities with the ability to change over to another geometry or part in a short period of time.

Doar said the best example of this is five years ago when TRUMPF invested in and built a Smart Factory in Hoffman Estates, Ill. (part of the Chicagoland region), to showcase the company’s machines and the use and connectivity of automation for short-run precision sheet metal fabrication. The Smart Factory interlinks the sheet metal process chain — from the commissioning of a sheet metal component, through design to manufacture, and on to delivery, according to the TRUMPF website. The Smart Factory offers a seamless interaction of people, machines, automation and software.

Technologies for Success

When it comes to what’s new and latest with TRUMPF, Doar emphasized TRUMPF likes to highlight its advanced technologies that ensure high-volume and high-mix factories that compete on a global scale can produce parts efficiently and at high quantities. He pointed out the lawn and garden industry, for example, which is a fragmented market consisting of large OEMs and smaller job shops. The networks of job shops provide important services to OEMs, and these job shops rely on high-performing machines to meet the expectations of their customers.

Doar pointed out that the TruLaser 1000 Series fiber is an affordable machine tool with a high-quality laser that is available in two models and is an ideal product for shops that don’t necessarily have the demand to operate around the clock, but they still have the need for a superior quality machine that is productive, reliable and flexible. The machine cuts a wide range of sheet thicknesses, from foil thickness materials to 1-inch-thick plates.

TRUMPF offers a new program where fabricators can pay for the use of the higher laser power only when they need it. Power by the Hour is an on-demand payment system that allows users to upgrade a machine’s laser power on the fly, making the decision process about which laser power to purchase much easier for many customers.

TRUMPF has also developed the TruLaser Weld 1000, which will most likely be on display at this year’s FABTECH being held in Atlanta in November. “What is not well known is that the laser is also a joining tool,” Doar said. This automated laser welding system is easy to operate and program and companies can start welding within a few hours of training. The machine offers the quality, productivity and design freedom lasers can provide. Depending on a shop’s demand they can weld one large component or smaller ones in serial operation working parallel to production.

Doar said TRUMPF also offers the TruArc Weld 1000 for customers who want to use a more conventional power device to join pieces of metal together. The machine, which will be on display at the September IMTS show in Chicago, comes with a collaborative robot (cobot), which allows the creation of new programs to be performed intuitively, instead of manipulating code. Inside the machine is a partition that can be moved up and down, allowing users to divide the working area and select between welding in a single-station operation or a two-station operation. The cobot travels between two workstations along a linear axis; so, while the cobot is welding on one side, an operator is on the other side setting up a part.

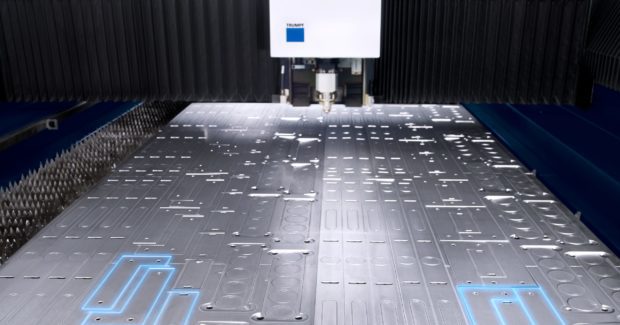

When it comes to specific laser products for accurately cutting flat sheets, one product is the TruLaser 5030 fiber, which is ideally suited to small and medium lot sizes where components are frequently changed. Doar said the 12-kilowatt laser ensures extremely productive and autonomous flatbed laser cutting. He added the product is especially attractive due to the speed of its drives. “The faster you can go — as long as you can be accurate — the more productive and higher performing you will be,” Doar said. “And our ability to move the different axes at very high rates of speed and the ability to manage the laser in those high travel rates is a core competency of TRUMPFs.

“So, after the part is cut flat, how does TRUMPF form it?” Doar continued. “Say, I was working with a company that builds metal doors: how do you build the door frames? After you have cut it in a flat you have to bend it so that it creates a three-dimensional shape.”

TRUMPF’s press brakes are known as the TruBend series. The newest series is the TruBend 5000, a state-of-the art bending machine with a wide range of unique technologies to assist the operator — active angle compensation, for example. Users can also select a bending machine combined with a BendMaster robot, which utilizes a robot designed and built by TRUMPF, to support the bending process and move the operator away from the pinch point. “It is a very useful tool in the United States because it is using automation to increase bending productivity and quality,” Doar pointed out. He added that this frees up a skilled worker to move to a different position on the factory floor, increasing the throughput and the performance of the manufacturing process.

Smart Factory “Spines” Move Operations Forward

Doar emphasized TRUMPF assists its customers through its technology and services so that customers can perform better every day. “I have so many fabulous customers that I admire because they really have courage,” Doar said. In Fort Worth, Texas, a South African company has established operations and has created a smart factory to manufacture metal canopies for the back of pickup trucks. The company, SmartCap, manufactures five-piece modular truck cap systems and offers sport, adventure and other commercial activities so users can customize the caps based on their needs.

The vision of Mike Voss, the CEO and owner of the company, is to create medium- to high-end caps that are made of metal as opposed to fiberglass. “Our machines match their automation and flexibility needs,” Doar said. SmartCap uses the TruLaser Center 7030, a fully automated flatbed laser cutting machine, and the only machines on the market that can flexibly cut a part of any size and shape, sort it and stack it completely autonomously, Doar stated. The TruLaser Center’s advantage is that other machines rely on a flying optic design where the laser center features a “hybrid axis.” TRUMPF Smart Factory solutions can provide cutting and bending technology that are connected by a “spine,” the automated material storage tower, as well as software that organizes the entire process. Stacks of parts can even be picked up by an autonomous guided vehicle, which moves them to the welding line, and then to the paint line.

Doar noted there are various and fascinating elements to TRUMPF’s products. “I am a big supporter and fan of manufacturing and particularly manufacturing that utilizes our types of machine tools and lasers to enhance the performance of our customers,” he said. “We have this group of smart and devoted people that support our customers during the duration of the use of our equipment.”

Doar also pointed out the world’s business climate is presenting TRUMPF’s customers with a remarkably interesting landscape. “It is undisputed the U.S. economy and the world economy are turbulent,” Doar said. “How does TRUMPF see it? In the United States, we see the risks, but these risks can also create opportunities for our customers. And, of course, when I say customers, we offer the enabling technologies they are relying on. There is a growth aspect to our business right now in the United States that is substantial.”

Tragedy Demonstrates the Resilience of TRUMPF

On September 2, 2021, a tragedy occurred when a small plane crashed and killed four people, skidding into TRUMPF’s Farmington, Conn. factory and significantly disrupting production. As of this writing, TRUMPF’s operations were still recovering; however, the company continues to support and work toward meeting the needs of its customers throughout North America.

In part, TRUMPF can navigate the challenge thanks to the fact that company officials devote so much of sales to research and development initiatives. The Leibinger family owns TRUMPF and devotes 10 percent of the company’s sales to innovation and R&D efforts. “If you are a $4 billion business and every year the R&D can generate a budget of over $400 million that puts us in a good position for our customers to feel confident that we are committed to creating the right tools that they need,” said Burke Doar, executive vice president, TRUMPF Inc. (In 2020/21, TRUMPF Global employed 15,000 people and generated sales of nearly $4.2 billion.)

Doar said customers tell TRUMPF what types of machines they require for success and the company builds the machines they request. “And we have an ownership structure and a management team led in the United States by our president and CEO Lutz Labisch that enables us to do that here,” Doar noted.

TRUMPF Committed to Zero Unplanned Downtime

Software is the glue of a smart factory, connecting various machines in real time and keeping customers informed about what is happening on their shop floors, said Burke Doar, executive vice president, TRUMPF Inc. “Imagine a world where we are creating software that helps us look ahead and anticipate a potential stoppage and alerts the customer,” he said. Manufacturers are looking to artificial intelligence to achieve the panacea of zero unplanned downtime in their processes.

“We are committed to that aspiration at TRUMPF because that is very important to our customers,” Doar said. “The investments they make, they make them on a calculus that the reliability of the equipment will be high. In order to enhance that likelihood, we have to build software that keeps everyone informed before an accident occurs.”

To that end, TRUMPF, which has been developing software for years, acquired Lantek in 2021 to further strengthen its software portfolio. Lantek has been a leading sheet metal software provider for more than 35 years.

“Our customers’ process is our focus — with Lantek, we comprehensively cover the sheet metal process chain, even with machines from different manufacturers,” said Thomas Schneider, managing director of machine tool development at TRUMPF. “In this way, we are taking another big step toward efficient and connected sheet metal production and enriching the Smart Factory solution portfolio.”

Subscribe to learn the latest in manufacturing.