Higher wear resistance and longer tool life in hard turning applications up to 58 HRC with Kennametal’s KYHK15B™ grade

New ceramic grade delivers highest productivity when

machining hardened steels, high-temperature alloys, and cast

irons.

Posted: August 12, 2022

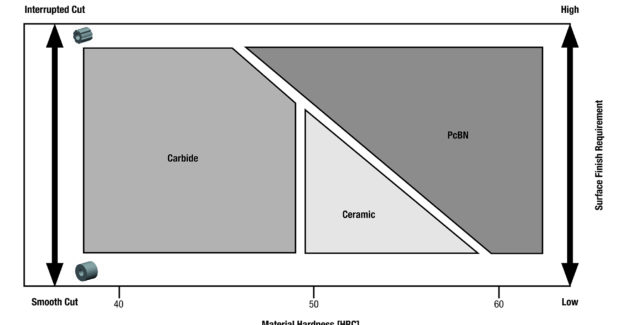

economic alternative to PcBN inserts when machining hard materials >48 HRC.

Kennametal has introduced its latest ceramic turning grade, KYHK15B™, designed to deliver increased productivity and lower cost per edge in hard turning operations. The new grade provides greater depth of cut capabilities than PcBN inserts when machining hardened steel, high-temperature alloys, and cast iron, as well as maximum tool life and wear resistance for the most demanding turning applications.

“KYHK15B provides excellent edge stability, high chipping resistance, and a PVD gold coating makes wear progression identification very easy. From smooth and varying depths of cut to heavy depths of cut, KYHK15B can be an economic alternative to PcBN inserts,” says Robert Keilmann, Product Manager, Kennametal.

KYHK15B builds on an existing line of high-performance ceramic turning grades, providing manufacturers a productive solution for hard turning applications even in varying or heavy depths of cut. Click here for more information: KYHK15B.

KYHK15B is a ceramic grade designed for machining of hardened steel (>45 HRC), as well as finishing of cast iron and high temperature alloys. KYHK15B is ideal for continuous and varying depth of cuts and provides greater depth of cut capabilities. The PVD coated hard turning grade, provides maximum wear resistance, and maximum tool life. The new coating with its gold color enables easy wear progression identification. State-of-the-art insert and coating technology provides tighter honing tolerances, leading to higher cutting edge stability, better chipping resistance, and better surface quality.