Introducing Clean Tube Laser Processing

Automatic spatter protection represents a significant increase in productivity when utilizing tube laser cutting lines.

Posted: August 24, 2022

THE CUTTING EDGE

For many years now, the business of processing metal tubes and profiles using lasers has been growing in North America. Tubular profiles have always lent very specific advantages to a manufactured product, such as excellent strength and rigidity relative to weight. Compared to sheet materials, however, profiles require somewhat specialized handling techniques. In most factories, processing of tubular profiles has typically been done with tools like power saws, drill presses, and machining centers in operations that require significant handling time for each manufacturing step.

No wonder then that tube laser processing has advanced so rapidly as the preferred tool for manufacturing these components, since the tube lasers can perform many types of operations rapidly and precisely, with little or no interaction from the factory workforce. In addition to making tube processing faster and more flexible, tube laser processing also introduces a new challenge for fabricators: spatter inside the workpiece.

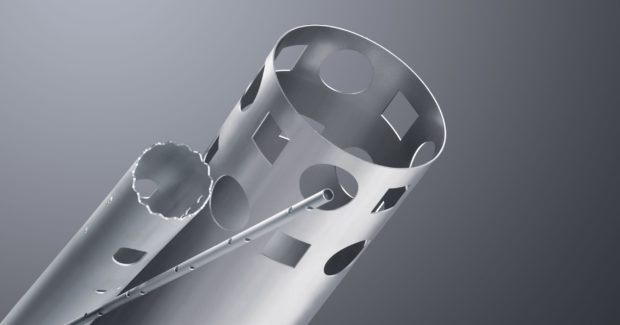

Cutting metal with a laser beam, regardless of the specifics in each case, always involves using the intense heat of the laser to melt or vaporize the raw material, plus a jet of gas to remove the melted/vaporized metal from the kerf. In sheet processing, this is straight-forward: The sheet is suspended horizontally below the laser cutter, and the ejecta from the cutting process is directed downward from the workpiece into the bottom of the machine. With tubular profiles, however, while we burn through one side of the workpiece, there is always another finished side opposite. This means the ejecta from the laser-cutting process ends up partially spattered across the inner surface of the tube, leaving a residue of slag and metal dust on the inner walls of the workpiece. Because the spatter is comprised of molten metal, it is abrasive and also adheres rather strongly to the workpiece.

In some cases, this “spatter effect” inside the finished parts doesn’t matter; the component will be welded into an assembly, and the interior condition of the tube has no bearing on the functionality of the assembly. In other situations, this spatter can be a problem that affects functionality and therefore must be addressed. When this happens, fabricators must generally resort to time-consuming and labor-intensive clean-up strategies for the parts. It doesn’t eliminate the advantages of tube laser cutting; still, if there were a more automatic way to deal with the spatter, this would represent a significant increase in productivity for tube laser cutting lines.

Automatic Spatter-Protection Devices

This is where some exciting technology comes into the picture. Automatic spatter-protection devices are creating the possibility to deal with this challenge right on the tube laser machine without any secondary handling. One new development along these lines offers great promise for fabricators that require internally clean tubular components: Spatter Guard. This technique involves using a moveable nozzle to spray a protective fluid coating inside the walls of the tube prior to laser cutting. This process is handled at the start of the machining cycle while the tube is being loaded by the automatic loader. The water-based protective fluid creates an interference layer on the inner surfaces of the tube that helps prevent spatter from adhering. This improves the efficiency of the vacuum-suction system that is trying to pull dust out of the tube, so less dust and slag remain in the tube after processing. Because of the protective fluid, any slag which remains on the inside of the tube will be loose, and easier to remove completely with a secondary step.

Spatter Guard works with round and rectangular tubes with as narrow an inside diameter as 1.2 inches and can fully protect the interior of raw materials ranging between 16-and-21 feet in length. Special closed profiles may also be possible to process with Spatter Guard; but consultation with an expert is required to verify specific requirements. The Spatter Guard technology can support clean processing of tubular components up to approximately 0.32-inch wall thickness, so the useful application range is broad.

How much savings this system can help your tube cutting process achieve will depend on the components in question; a reduction in manual cleaning time of 50% compared to processing without Spatter Guard is not unusual, meaning the potential savings become larger if all or most of the cut tubes will require cleaning.

All in all, this new strategy to improve the quality of cut parts fresh off the tube laser machine means another big advance in productivity is possible for contract shops and OEMs in the tube processing business. It’s also a great example of how equipment manufacturers can respond to the evolving needs of manufacturing businesses with new technology. Additionally, because cleanup of cut tubes is a necessary (but not necessarily value-adding) manufacturing step, the more it can be automated, the better for factory efficiency in general. Technologies like Spatter Guard are steadily advancing tubular component manufacturing toward a completely hands-free manufacturing process, which is excellent news for anyone wanting to get more tube work done with the same amount of people and floorspace.

Subscribe to learn the latest in manufacturing.