Machining Centers and EDMs Provide Complete Solutions

Shops collaborate with tool manufacturers to successfully achieve efficient machining of a wide range of materials.

Posted: August 24, 2022

Industry leading suppliers offer new and upgraded machining centers and EDMs, combining their decades of experience and innovations to create machines that enable the manufacture of precision parts. Shops can access and work with a wide range of applications designed for greater productivity.

EDM Machines Deliver Precision Part Generation

For customer growth and success, GF Machining Solutions (Lincolnshire, IL) offers integrated problem-solving solutions including the new CUT X 500 and CUT P 350 Pro wire cutting EDM machines for precision part generation. Capitalizing on more than a century of EDM technology, the CUT P 350 Pro and CUT X 500’s new Uniqua human/machine interface delivers optimal functionality and ergonomics in a 19″ vertical touchscreen, full keyboard and mouse. Abundant automation options add to the machine’s scalable flexibility, with optimized production for electronics, automotive, medical and mold and die manufacturers through more than 600 pre-programmed cutting processes.

The AgieCharmilles CUT X series holds extreme accuracies in machining positioning and pitch. Developed to provide high precision and thermal stability in large runs of complex components, including stamping tools, multi-cavity molds and micro components, the CUT X 500 and all other CUT X machines feature adapted mechanical structures, dedicated machine calibration and testing to deliver pitch accuracy as low as 1.0 µm. High-precision axes, short measurement loops, dual measurement on all axes, consistent isolation of the EDM area from heat sources and submerged working areas optimize conditions for micro applications. Two-spool Automatic Wire Changer technology and an onboard Job Management System help further reduce processing time and simplify job prioritization.

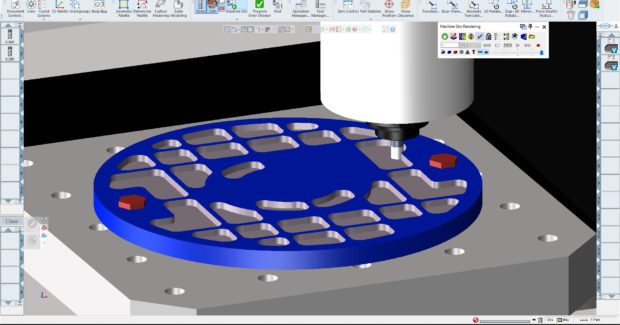

New Version of CAD/CAM Software Focuses on Product Quality

CAMBRIO, a leading CAD/CAM innovator in the production machining industry, has released GibbsCAM 2022. GibbsCAM (Moorpark, CA) integrates with all major CAD systems and supports 2D to 5-axis milling, turning, multitask machining (MTM), and wire EDM. The latest release includes several CAD enhancements for solid and surface modelling which include the ability to extrude multiple bodies with taper, and to create surfaces as a stitched body directly from closed 2D geometry. In addition, users can automatically create trimmed planar surfaces in any orientation at geometry depth instead of the CS plane. Further developments include new alignment capabilities which allow straight edges of solid bodies to be easily aligned with the working coordinate system in preparation for machining, and a new sectional view slicing plane can be dynamically moved in any direction to easily view and select features within the interior of a solid body.

Machine Shop Capabilities Offered as an Independent Service

For more than 55 years, Guill Tool & Engineering (West Warwick, R.I.) has provided tooling for the aerospace, medical, and oil and energy industries, among others. Guill offers its substantial machine shop capabilities as an independent service to customers. It offers merchant machining services to the global aerospace industry, as well as a medical machining program.

Guill offers 5-axis machining centers, high precision machining and full wire EDM capabilities, highlighted by a .008” hole popper. Guill machines super alloys and exotic metals to close tolerances.

Its CNC milling machines offer resources needed to successfully fulfill the most challenging aerospace parts and tooling. The precision of CNC turning is offered for quicker production that meets rigorous standards on short and medium runs, regardless of the complexity of the parts. Guill’s multi-axis machines can produce a variety of sizes, complex engineering and geometric intricacies. Prototype machining and rapid manufacturing enable engineering to develop and innovate solutions with the ability to respond quickly and modify parts. Wire EDM eliminates the force put on part surfaces. This protects intricate and fragile tooling, plus it provides higher tolerances and accuracy.

NEO Series of Machines Feature Numerous Upgrades

Part of Mazak Corp.’s (Florence, KY) next-generation NEO Series machines is the HCN-6800 NEO Horizontal Machining Center. NEO Series machines take the previous generation’s performance to new levels of efficiency and ease of use through numerous upgrades. The machines sport fully redesigned enclosures, best-in-class standard and optional equipment and improvements throughout to provide fast, optimal solutions for a wider range of part-production applications.

The HCN-6800 NEO features upgrades to its spindle, table and magazine including a new standard 43-tool drum-type magazine that reduces tool exchange times. For ease of maintenance, the machine incorporates hydraulic/motorized pallet changer mechanisms and an easy to access maintenance panel. A faster servo-driven ATC door design also accommodates longer tools.

New Okuma Machines Available in the Americas

Okuma America Corp. (Charlotte, NC) offers two new machines in the Americas: the MA-8000H and the VT1000EX. The MA-8000H is the latest addition to the horizontal machining center lineup. This new CNC machine was designed for greater productivity when manufacturing large parts, without compromising machining capacity, reliability or accuracy. The machine’s impressive work envelope and expansive travel ranges (X axis: 1,400 mm, Y axis: 1,200 mm, Z axis: 1,350 mm), coupled with a highly rigid bed and cast-in ball screw mounts for highly accurate drive and positioning, make the MA-8000H ideally suited to cut medium-to-large workpieces. Additionally, powerful spindle options effectively handle materials across the metal spectrum. The machining center is engineered with Okuma’s proprietary Thermo-Friendly Concept, a feature that practically eliminates thermal deformation during the machining process. The machine is well-suited to adopt automation systems such as automatic pallet changers, flexible manufacturing systems, and a variety of robotics to enhance productivity.

The VT1000EX, a machine tool with the highest machining capability in its class, provides new levels of productivity due to its highly rigid mechanical configuration, extreme thrust and torque. This large vertical lathe is ideal for industries looking to dramatically reduce cycle time for difficult-to-cut materials. The VT1000EX weighs 41,800 pounds and features a highly rigid construction and structural reinforcement, executing stable operations for long periods. This machine features wide guideway spacing, rigid and precise ball screws for both the X and Z axes, and a heavily cross-ribbed casting, which provides ultimate stability during ultra-heavy cutting of large workpieces.

The machine’s spindle is capable of a maximum power output of 55 kW, maximum torque of 5,310 Nm, and thrust of 30 kN on the X and Z axes. This makes heavy-duty cutting for difficult-to-cut materials possible and can even reduce cycle time by up to 51%. The machine comes standard with a 36-tool magazine for continuous, long-run operation. Tool life is extended by a high-pressure coolant system, and chips are quickly removed with an enlarged chip evacuation system.

Two in One: VHybrid 260 Masters Grinding and Eroding

Sharpening specialist VOLLMER of America Corp. (Pittsburgh, PA) has launched the VHybrid 260 Grinding and Erosion machine, which combines technologies and experience that VOLLMER has gained in the fields of grinding and eroding over many decades. The new machine can be used to machine solid carbide or PCD (polycrystalline diamond) tools in one setup.

The VHybrid 260 not only provides tool manufacturers with high efficiency for reduced machining times, but also maximum precision. A wide range of automatic settings enable unmanned use of the machine around the clock. With the new VOLLMER tool manager, users can manage the automatic switching of up to eight grinding or eroding wheels intuitively.

The VHybrid 260 is based on multi-layer machining, which is implemented through two vertically arranged spindles. Here, VOLLMER is using the tried-and-tested technology of its VGrind grinding machine series. With the VHybrid 260, the bottom spindle can be used both for grinding and for eroding, while the top spindle is reserved exclusively for grinding. “Tool manufacturers today are often development partners for their customers and are involved in the tool planning phase from the outset in order to achieve efficient machining of a wide range of materials,” said Dr. Stefan Brand, CEO of the VOLLMER Group. “And whether carbide or diamond tools are required, the hybrid machining technologies in our VHybrid 260 enable precise machining of a variety of rotary tools, such as drills, milling cutters or reamers.”

Subscribe to learn the latest in manufacturing.