Mikron Tool’s “Crazy” Innovations at the IMTS 2022

At IMTS, Mikron Tool will be premiering the results of its intensive development work.

Posted: August 26, 2022

Eagerly awaited, the IMTS is finally opening its doors again after a forced break due to the pandemic. And, as always, Mikron Tool will be there. In the meantime, the R&D department has been running at full speed, always with a focus on the efficient machining of demanding materials in the micron range.

Mikron Tool will be premiering the results of its intensive development work at this year’s IMTS:

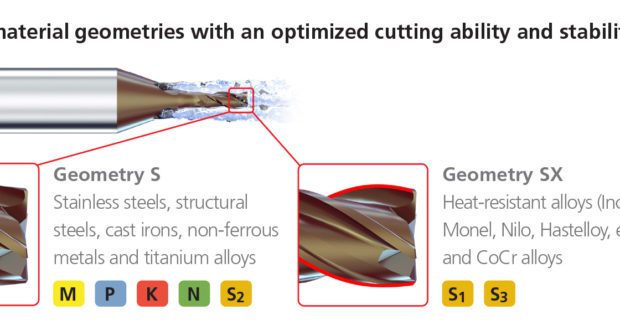

Micro milling cutters with new high-performance geometries

The new CrazyMill Cool Micro with integrated cooling is a new type of high-performance micro milling cutter for roughing and finishing difficult-to-machine materials. It is available in diameters from .008″ – .039″ (0.2 to 1.0 mm) with a milling depth of up to 5 x d.

Thanks to material-specific cutting edge geometries, which were specially developed for the different machining behaviour of materials, the new micro milling cutter combines excellent cutting ability with high stability. The result is a significantly higher removal volume with high shape accuracy and a longer tool life. A “small” world sensation!

New drilling technology for titanium

The high-performance material titanium is a machining challenge. In addition: not all titanium is the same. Pure titanium and alloyed titanium, for instance, both present different machining characteristics. That’s why Mikron Tool has developed perfectly tailored drills for the various types of titanium: the CrazyDrill Titanium PTC for pure titanium and the CrazyDrill Titanium ATC for alloyed titanium, both guarantee ambitious cutting values and process reliability. This development offers enormous innovative power for the titanium processing industry. A drill for all types of titanium!

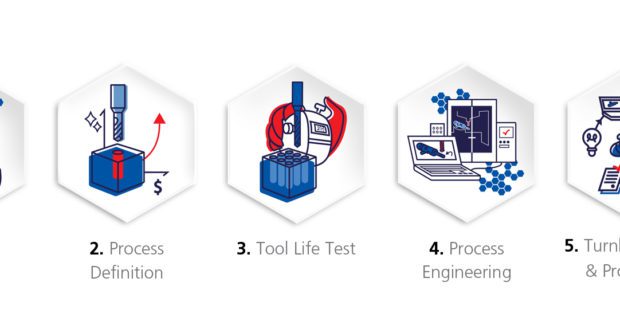

CrazyService Products novel engineering services

Mikron Tool expands its product portfolio and offers professional project management in the field of high-performance machining for demanding materials.

The offer includes: tool evaluation, optimisation or redefinition of a process or critical sequence, tool life testing and even drafting of complete projects. Always under the condition that the preferred solution offers the customer clear added value.

Machining companies can now benefit from Mikron Tool’s capacity and expertise when outsourcing their pilot projects. You can expect individual machining solutions from Mikron Tool for the efficient component production with high added value and complexity.

Mikron Tool considers always standard market requirements

For the US market Mikron Tool provides tools with diameters in inches, from 1/64″ up to 1/4″ depending on the product line. Especially in the high-tech industries that are very relevant for the US market, such as aerospace, many dimensions are used in US standard units (inches). The need for such dimensions is increasing and therefore Mikron Tool has introduced main dimensions in inches for a wide range of its drill and cutter families. The tool selection was based on the most used units in the industries concerned, with a special focus on tools for difficult-to-machine materials such as stainless steel, titanium, and superalloys.

IMTS: West building / Booth #432279

Subscribe to learn the latest in manufacturing.