Walter’s new Tiger·tec® Gold PVD Grade for Universal use in Walter Milling Tools

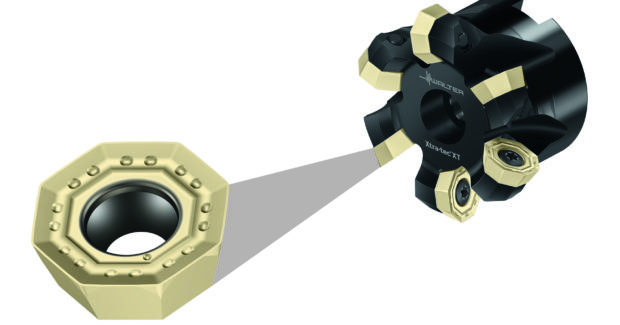

WSP45G is a new generation of indexable carbide inserts for milling that dramatically expands capabilities for slotting, shoulder and copy milling.

Posted: August 12, 2022

Walter has introduced its Tiger·tec® Gold PVD grade The new grade can efficiently process demanding machining applications such as interrupted cuts and difficult materials.

This new grade is now capable of longer tool life, greater reliability, and approximately 30 percent greater performance in stainless steels (ISO M) and heat-resistant super alloys (ISO S), and up to 75 percent greater performance in steels (ISO P) than comparable grades. With the launch phase now complete, the PVD grade WSP45G Tiger·tec® Gold can be used universally in all standard Walter milling cutters.

The key to the grade’s performance is its next generation coating technology and its special layer structure. The gold colored ZrN top layer facilitates exceptional low-friction characteristics as well as excellent wear detection, thus making it possible to utilize the full potential of the indexable insert to extend tool life. Next, multiple layers of aluminum oxide (Al2O3) increase the inserts temperature resistance.

All are applied on top of a TiAlN base layer and a premium carbide substrate as a foundation, greatly increasing the overall wear resistance. These properties make the new inserts ideal for challenging conditions, such as interrupted cuts, long overhangs with a tendency to vibrate, or for wet machining.

Walter, a global leader in the metalworking industry for over 100 years, offers a wide range of precision tools for milling, turning, drilling and threading applications. The company helps customers in the aviation and aerospace industries, automotive, energy, and general metalworking industry improve process reliability and increase productivity. As an innovative partner capable of creating digital process solutions for optimal efficiency, Walter is pioneering Industry 4.0 throughout the machining industry. With Regional Headquarters in Waukesha, WI, Walter markets its competence brands Walter, Walter Titex, Walter Prototyp and Walter Multiply through a network of channel partners and field engineers across the USA, Canada, Mexico and Brazil. www.walter-tools.com/us

Subscribe to learn the latest in manufacturing.