At FABTECH, AIDA-America will Demo Press Tech with Multiple Presses and Control Systems

Company will stamp progressive die parts and demonstrate silent blanking motion profile via multiple direct-drive servo presses and control systems.

Posted: September 23, 2022

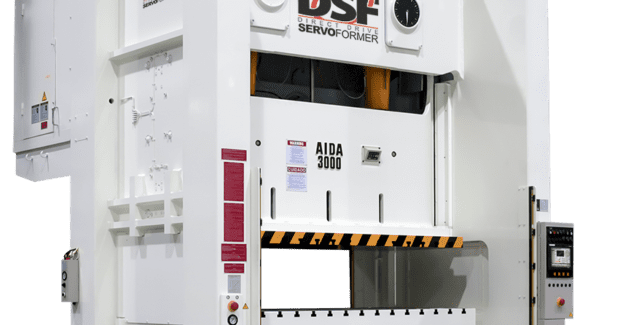

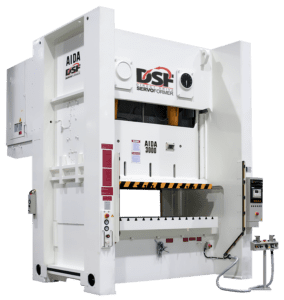

AIDA-America will partner with A-G Tool & Die, Dallas Industries, Pax Products, Inc., and Tower Metalworking Fluids to demonstrate a 200-ton straightside servo press, as part of a full progressive die production line stamping parts. This two-point, direct-drive straightside servo press, model DSF-N2, combines the rigidity of a unitized frame with the flexibility of freely programmable servo motion. Step-by-step, easily programmable slide motion profiles via an intuitive HMI allow quick modifications to optimize productivity and improve part quality. Like all AIDA servo presses, this model features an AIDA designed and built, low speed, high torque servo motor specifically manufactured for stamping press applications. Other standard features include a 6-point slide guide system with easy gib adjustment to maintain parallelism and resist off-center loading; a recirculating oil lubrication system that provides clean oil in metered amounts to all bearing points; the industry’s fastest Hydraulic Overload Protection System (HOLP) with a 10 millisecond overload response time to achieve zero pressure; and an Energy Conservation and Optimization (ECO) system that efficiently stores energy in a long-life capacitor system to optimize energy consumption. The DSF-N2 Series product line is offered in a range of tonnages from 110 to 300.

The second press on display, a DSF-C1-1500A, 150-ton, direct-drive gap frame servo press, will be blanking parts with AIDA’s optimized servo silent blanking stroke motion profile, which can only be achieved on a servo press. AIDA-America’s A-Series single point, direct-drive gap frame servo press showcases AIDA’s exclusive Allen-Bradley control, featuring an ergonomically designed 12 in. swing-arm mounted color touch screen HMI with optical run buttons to provide the highest level of safety while helping to reduce operator fatigue. Other control highlights are an Allen-Bradley servo motion controller on ControlLogix® platform, 150 job recipe storage, integrated tonnage monitor (peak only), step-feed (CNC handwheel) slide motion control for ease of die set-up, 8 PLS cams, 8 channel die protection with PNP/NPN signals, and display of actual and virtual crank angles. Additional DSF-C1-A Series features are a next generation servo motor with 5-10% higher speeds than AIDA’s previous generation gap frame servo presses, a capacitor-based Energy Conservation and Optimization (ECO) system that reduces peak energy draw, and a state-of-the-art Electronic Over Load Protection (EOLP) system that monitors applied torque throughout the stroke to prevent overloading. The DSF-C1-A Series product line is offered in a range of tonnages from 80 to 250.

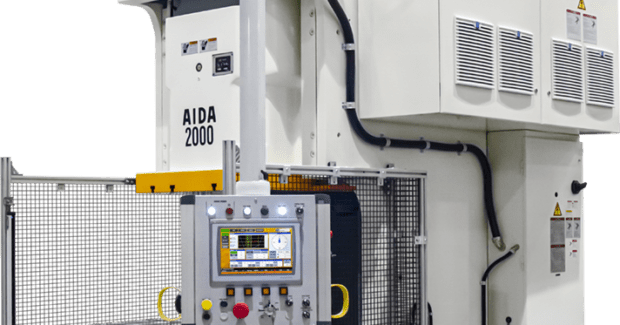

AIDA-America will also exhibit its exclusive Allen-Bradley based servo press control, the latest in servo press control technology, for servo presses from 315 – 3,500 tons. This fully operational and interactive 19 in. PC touch screen Allen-Bradley control will demonstrate several servo press stroke motion profiles in real-time on a virtual press. Control features include direct access to a pdf of the press manual and display of actual and virtual crank angles.

Knowledgeable AIDA-America associates will be available to discuss AIDA’s full metalforming equipment line-up, including examples of production optimization driven by AIDA DSF Series servo presses used in the stamping industry. They will share how AIDA presses can help maximize stampers’ productivity and profit in the press room. Please visit booth B6007 to experience first-hand why AIDA continues to be the stamping press technology industry leader.

Subscribe to learn the latest in manufacturing.