Four Major Trends You’ll Experience at FABTECH 2022

Trends impacting the manufacturing sector, topics of which will be present at FABTECH, include 3D/additive manufacturing, cybersecurity, workforce/labor shortages and smart technology/IoT.

Posted: October 26, 2022

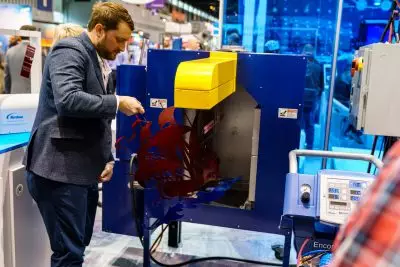

At FABTECH 2022, you’ll find all the key insights into the latest trends that are making an impact on the manufacturing industry this year, including 3D/additive manufacturing, cyber security, workforce/labor shortages and smart technology/IoT. Join us November 8-10 at the Georgia World Congress Center in Atlanta to report on these latest trends driving the industry forward.

At FABTECH 2022, you’ll find all the key insights into the latest trends that are making an impact on the manufacturing industry this year, including 3D/additive manufacturing, cyber security, workforce/labor shortages and smart technology/IoT. Join us November 8-10 at the Georgia World Congress Center in Atlanta to report on these latest trends driving the industry forward.

Here’s more on the latest trends in manufacturing and where you can find them at FABTECH 2022:

Trend 1: 3D/Additive Manufacturing

Additive Manufacturing/3D printing has been one of the fastest-growing technologies of the 21st century and the global market size is expected to continue to grow. It has transformed the methods manufacturers have traditionally used to create various parts and products, bringing tremendous benefits to the industries that have embraced it.

“AM continues to grow at amazing rates. While many users see this as a competitive advantage, applications are becoming more visible in every market. Understanding how to successfully engage AM can help get your manufacturing to higher levels of efficiency—potentially to the production of products that might not have been possible before.” – Carl Dekker, President at Met-L-Flo Inc.

Where you’ll find it at FABTECH:

- Dedicated 3D/Additive Manufacturing Conference Track with sessions focused on robotic and laser solutions, design tools, safety and power quality solutions, and more

- 3D/Additive Pavilion in Halls B/C: Featuring top companies including Markforged, Formlabs, AddiTec, Creaform, Raise3D, and more

Trend 2: Cyber Security

It’s not a matter of if a cyber attack will happen, it is a matter of when. Cyber threats and data breaches are becoming more sophisticated and should be top-of-mind for all organizations. In fact, a 2022 IBM Security report reported that “for the first time in five years, manufacturing outpaced finance and insurance in the number of cyber attacks levied against these industries, extending global supply chain woes.”

“The task of implementing cybersecurity protections for complex, connected systems doesn’t have to be complex itself. All-in-all, tight collaboration among all personnel and purposeful consideration of protections that apply to your organization will be the keys to successfully navigating the ever-growing complexities in Industry 4.0.” – Jeremy Dodson, CISO at NextLink Labs

Where you’ll find it at FABTECH:

- Leadership Exchange Panel: Considerations to Improve Your Cyber Security Strategy

- Conference sessions on building strong cybersecurity defense plans, developing and testing incident response plans, and more

Trend 3: Workforce / Labor Shortages

According to the Deloitte 2022 Manufacturing Industry Outlook, record numbers of unskilled jobs are likely to limit productivity and growth through the end of the year. While the 1.4 million U.S. manufacturing jobs lost in the early days of the pandemic have returned, the workers have not. While staffing troubles may continue to make headlines, the industry is finding innovative ways to overcome these challenges.

“The view of manufacturing by young generations is a dark, dirty, and dull industry where their parents used to work. But adopting technology that is innovative and removing the dull tasks will allow future workers to drive more purpose in their job and create a culture that is based on what they grew up with.” – Jacob Hall, Social Influencer at Manufacturing Millennial

Where you’ll find it at FABTECH:

- Leadership Exchange Panel: Planning for the Future of Work: How New Technology is Redefining the Workplace

- Workforce Development Conference Track with sessions focused on hiring and retention, millennials & Gen Z in the workforce, creating a culture of accountability and more

- Conference sessions addressing labor shortages, including those focused on technology and labor challenges, investing in robotics and more

Trend 4: Smart Technology / IoT

Labor shortages are expected to continue, and manufacturers will need to embrace smart technologies to remain competitive. Manufacturers are leveraging smart technology / IoT to achieve a variety of goals, including cost reduction, increased efficiencies, improved safety, meeting compliance requirements and product innovation. From condition monitoring devices and predictive maintenance/machine learning technologies to material handling, intralogistics and collaborative robots, smart technologies can help identify and solve problems and improve manufacturing performance.

Labor shortages are expected to continue, and manufacturers will need to embrace smart technologies to remain competitive. Manufacturers are leveraging smart technology / IoT to achieve a variety of goals, including cost reduction, increased efficiencies, improved safety, meeting compliance requirements and product innovation. From condition monitoring devices and predictive maintenance/machine learning technologies to material handling, intralogistics and collaborative robots, smart technologies can help identify and solve problems and improve manufacturing performance.

“For manufacturers looking to overcome their workforce and production challenges, smart technologies are imperative. But without first building the right company foundation, the best and more innovative technologies can fail, collecting dust in a corner. Manufacturers need to engage the people in the workforce. Front-line workers run the business and know where the improvements need to be made. Then good processes need to be documented or created. Only then does a technology have a chance to succeed.” – Will Healy III, Global Industry Segment Leader – Welding at Universal Robots

Where you’ll find it at FABTECH:

- Smart Manufacturing Bootcamp covering integrating robots into the workforce, AI insights, CMMS Systems and cyber security

- Smart Manufacturing Conference Track with sessions topics on IIoT and agile development, condition and production monitoring, artificial intelligence, and more

Subscribe to learn the latest in manufacturing.