Increase Your Shop’s Productivity with the Latest Portable Solutions

Leaders in metal forming and fabricating industry technologies continue to improve their products, resulting in increases to your productivity and the bottom line.

Posted: October 19, 2022

Mag drills, marking systems, bevellers and notchers are well suited to support activities taking place in both small job shops and large factories. These units and products are easy to learn, setup and operate, providing the power you require to complete a range of jobs, while at the same time ensuring consistency and repeatability. These products also feature built in safety features that contribute to longer product life and keep operators safe.

The HMD900: A Powerful Low-cost Mag Drill

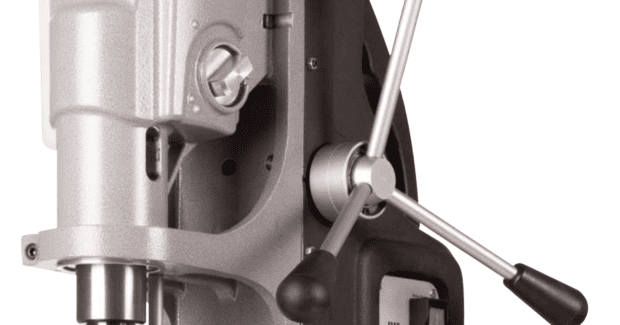

Hougen Manufacturing, Inc. (Swartz Creek, Ml) offers the new HMD900 portable magnetic drill. This model is a powerful lightweight no frills mag drill designed for general fabrication. While incorporating operator safety functions and many standard Hougen features, the HMD900 is an affordable cost point tool for the low volume user.

The HMD900 includes a hidden motor cord design that incorporates the cord into the drill’s motor casing and housing, which increases the safety of the drill and reduces maintenance to a minimum. Powering the drill is a proprietary Hougen motor with an aluminum casing to improve durability. The arbor system utilizes a 5/8″ slot drive for more rigidity, hole accuracy, spring slug ejection and quicker use of accessories such as drill chucks and countersinks. The unit features a more robust housing design with an ergonomic carrying handle and a spot to hold the hex wrench. A safety switch built into the base of the magnet shuts the motor off if the magnet were to disengage from the work surface.

The HMD900 magnetic drill weighs just 27.7 pounds (12.6 kg), measures 15-1/8″H x 6-3/4″W x 11-3/S”L (384 mm x 171 mm x 289 mm) and provides drilling capacities from 7/16″ up to 1-1/2″ (12-to-38 mm) diameter and 2″ (50 mm) depth of cut. The drill has an electrical rating of 9A and a 450 RPM motor. The HMD900 is made in the USA.

Automatic Hole Drilling up to 6” Diameter with MAB 1300 V

For large capacity drilling in steel, CS Unitec, Inc.’s (Norwalk, CT) MAB 1300 V portable magnetic drill has the largest hole cutting capacity in the industry — 6” diameter with annular cutters. The V model 1300 comes with an automatic feed and reverse motor, greatly reducing user fatigue and increasing cutting tool life and drill control. With any magnetic drill most of the cost will come from annular cutters and cutting tools. Improving cutting tool life can pay for a magnetic drill many times over. Automatic feed and feed rate control add improved chip flow and reduce the chance of annular cutter breakage, a costly concern on any large drilling job.

The MAB 1300 V can be used in either manual or automatic mode. The 1300 V’s powerful 20 amp/110 volt double-insulated, reversible motor is ideal for drilling structural steel and other metals. Designed for continuous use, the 4-speed oil bath gearbox is suitable for applications requiring high power. With the MAB 1300 V’s 12” stroke, other capabilities include large hole tapping up to 1-5/8” diameter, twist drilling up to 1-3/4”, countersinking up to 3” and reaming up to 2”. The MAB 1300 V has a 1-1/4” Weldon arbor with an adapter for 3/4”.

The high-density, three-coil magnet has a holding strength of up to 23,600 pounds, providing the pulling power required for heavy-duty drilling. The unit includes an integrated automatic cooling/lubrication system to increase the life of the annular cutters by reducing friction and wear.

For online: video link: https://www.youtube.com/watch?v=kcyvO6CnJbg

iTeach Jog and Teach Function

Kwik Mark Inc.’s (McHenry, IL) Dot Peen Marker, which is manufactured in the United States, gives you the ability to place high-quality marks on your products consistently and quickly, allowing you to be more productive. The patented iTeach Jog and Teach Function, the only pre-programmed Dot Peen Marker, allows you to use the marking tip as a “pointer” to define the text path. The iTeach now includes more features, upgraded controls and more memory. No prints or part dimensions are required, no measuring or layout tools are needed, and no programming experience is necessary. It really is that simple.

- Mark Text on a Radius-Touch any three points along an arc or hole and the machine will automatically figure out the radius, starting/ending angles and place the text perfectly on this radius.

- Mark Text on an Angle-Touch any two points along the angle/edge and the machine will automatically figure out the angle and place the text perfectly along this angle.

- Mark Text Within a Defined Area-Touch two opposite corners of a rectangle and the machine will automatically fit the text (both height and width) within this rectangle.

- Mark Text in Several Defined Locations-Touch one point per line of text to define the starting point of your text line and the machine will automatically set the X-Y position for the line.

Quick Change Fixtures for Patmark and MarkinBOX

MB Metal Technologies, LLC (Milwaukee, WI) is featuring the Quick Change Fixture for Round Part Marking, for both MarkinBOX and Patmark Dot Pin Marking machines. They are available in two marking window sizes; 15 mm X 33 mm, and 20 mm X 80 mm. Quickly and easily position your MarkinBOX or Patmark Dot Pin Marker, and securely fix your marker in position to mark round parts, tubes, poles, and bar stock (up to 62 HRC). Includes both a machined aluminum quick change base plate, for mounting your pin marker, as well as your choice of on/off magnets and/or adjustable jaws for easy and strong mounting to the round part.

Scotchman’s Grinders/Notchers Designed for Easy Setup

Scotchman Industries Inc.’s (Philip, S.D.) grinder/notchers are constructed with a heavy-duty base and frame, and are available in four models with grinding capacity ranging from 1/2” up to 4-1/2” O.D., depending on the model. Each machine operates smoothly with minimal vibrations and produces gap-free fits ready for welding. Scotchman’s grinder/notchers are designed for easy setup with one vise to hold all sizes of tube and pipe that is graduated in degrees and is equipped with a mandrel with centerline adjustments. Tool-free belt and mandrel changes make transitions quick and easy. Each model comes with two belts and two pipe mandrels. Optional mandrel sizes are available in a variety of sizes to ensure a gap-free fit.

The AL100U-01 series is equipped with a hand lever feed handle and manual vise that can be adjusted right or left. The AL100U-02 series is equipped with two handwheels and hand lever feed handle.

The AL150 and AL150-HS series are equipped with a two-axis precision cross feed table with both handwheels and hand lever feed handle. The AL150-HS series is ideal for stainless steel and aluminum, is 40% faster than the AL150 series, and has an additional high-speed parts grinder in the back.

Magnetic Drill Offers Continuous Feed for Maximum Consistency and Efficiency

WALTER Surface Technologies (Windsor, CT), a leader in surface treatment technologies for more than 60 years, offers the ICECUT 250 AUTO™, which is engineered for optimal productivity and safety on the job site. Designed with user productivity in mind, the ICECUT 250 AUTO magnetic drilling unit features a fully automatic drill feed. The continuous automatic feed ensures consistent, repeatable results, reduces the likelihood of breakage of the cutters and even allows multiple magnetic drill units to be used by one operator.

Thanks to breakthrough detection and auto return, this magnetic drilling unit is ideal

for a wide range of large volume drilling operations in industries such as metal fabrication, transportation and shipbuilding. Capable of operating on its own, it allows the operator to power multiple units at once with minimal physical effort and achieve maximum consistency and efficiency.

The ICECUT 250 AUTO is also equipped with the ACCUDRILL™ torque display which prevents the motor from overloading and reduces the risk of cutter breakage. Its advanced technology provides breakthrough detection and auto retract for consistent drilling. It also includes a morse tapper adaptor, making it compatible with twist drills, offering you endless possibilities.

Subscribe to learn the latest in manufacturing.