Partnership to Provide Complete Hassle-free Coolant Management Systems

Jorgensen Conveyor and Filtration Solutions and Will-Fill partner to offer customers coolant management systems such as PermaClean.

Posted: December 12, 2022

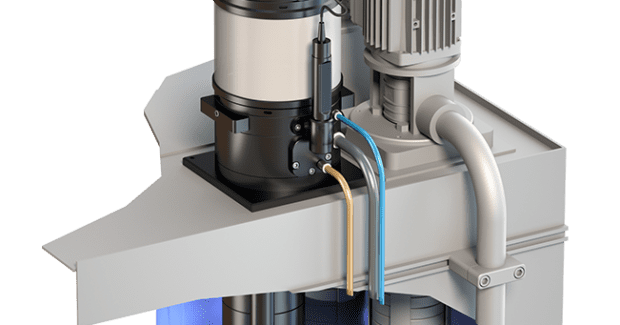

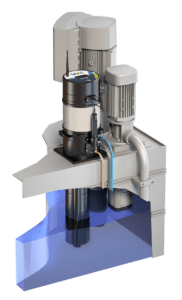

As of November 1, Jorgensen Conveyor and Filtration Solutions entered into a partnership with Will-Fill, a manufacturer of fully automatic coolant monitoring and managing systems. The strategic partnership allows Jorgensen to offer customers complete and worry-free coolant management systems, such as the company’s recently launched PermaClean, that provide both filtering and measuring capabilities for an all-in-one solution.

With the addition of the revolutionary Will-Fill add-on device, a coolant system can provide trouble-free care of metalworking emulsion by combining automatic measurement and analysis of fluid with faultless filling, permanent conditioning and timely reporting. The Will-Fill components are linked to a high-performance control unit, allowing the device to regulate and adjust the fluid level and the fluid condition automatically. Additionally, it can alert users when attention is necessary via wi-fi or lan network capability.

Will-Fill can be combined with Jorgensen’s filtration options, such as PermaClean. Coolant tanks equipped with PermaClean eliminate tank sludge, significantly reducing the labor required for frequent tank cleaning. Plus, when combined with the cyclonic filtration option and a Will-Fill, the system is fully automated and nearly maintenance free.

Will-Fill units are field retrofittable and can be added to almost any machine tool coolant tank and is machine tool brand agnostic.

“At Jorgensen, our goal is to provide customers with systems that make coolant management an invisible process within their machining operations,” said Karl Kleppek, President and COO at Jorgensen. “The combination of PermaClean and Will-Fill to our FlexFiltration systems portfolio uniquely positions us to deliver complete, fully automated, maintenance-free conveyor and filtration solutions-allowing users to return their focus to machining.”

Subscribe to learn the latest in manufacturing.