Refinements to Workholding Products Boost Performance and Save Money

Keep your workpieces in their desired positions by utilizing versatile, powerful and quick-change clamping and workholding devices.

Posted: December 27, 2022

TOOLING & WORKHOLDING

Workholding and clamping devices are increasingly easier to use, which includes an expansion of robotic and automation capabilities. Inventive designs and lighter weight devices, for example, ensure success in a variety of applications.

Smart Damper-Equipped Face Mill Holders are the Largest, Longest Mill Holders Yet

BIG DAISHOWA (Hoffman Estates, IL) has expanded its lineup of Smart Damper-equipped, arbor-style face mill holders. This new holder is the largest and longest milling tool BIG DAISHOWA has offered yet. It supports face mills with diameters of 3″, 4″, 80 mm or 100 mm with an arbor pilot diameter of either 1″ or 27 mm.

The Model SDF57 assembly has an outside diameter of 2.83″ and allows users of 3″ face mills to access up to 19.68″ of reach, the longest tool assembly in the industry using standard components. Face milling components used in construction equipment, aerospace and oil/gas industries will see the most opportunity for this tool holder with vibration dampening, where long reaches are common.

Smart Damper enables quiet, vibration-free milling, even in long-projection assemblies. The integral design of Smart Damper shortens the distance from the damping mechanism to the cutting edge. This produces higher damping effects to the tool assembly, minimizing chatter or vibration for better surface finishes and improved metal removal rates. This face mill holder is available for BBT50, BCV50 and HSK-A100 shank styles.

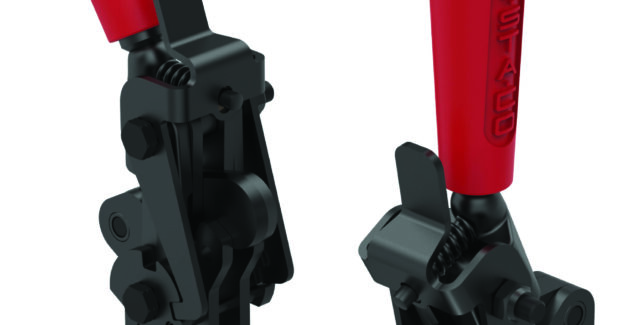

Two New Models Added to Heavy-Duty Manual Clamp Product Line

DESTACO (Auburn Hills, MI) has added two new models to its heavy-duty manual clamp product line. The 503-MLBR and 533-LBR models are extensions of the 503-MLB and 533-LB vertical toggle-lock clamps with the new versions featuring the patented Toggle Lock Plus system.

“The space-saving Toggle Lock Plus latch uses a locking disc to secure the position,” said Nina Wolleb, application engineering manager, Europe, for DESTACO. “This solution saves space and since no welding is required, is easy to implement. That provides additional safety and protection against unintentional opening and closing.”

The user-friendly new models allow for fast handling and enable their users to build up applications more efficiently with little interference contour. The 503-MLBR and 533-LBR clamps are fully interchangeable with models having the same specifications; other models are available upon request.

DESTACO, a Dover Corp. company, is a global leader in the design and manufacture of high-performance automation, workholding and remote-handling solutions.

Pipe Beveler End Prep Tools Handle Highly Alloyed Small Tubes

A family of right-angle welding end prep tools for highly alloyed small diameter tubes that require precision beveling prior to welding to assure high-integrity welds has been introduced by Esco Tool (Holliston, MA). The company is a unit of Esco Technologies, Inc.

The Esco Ground MILLHOG® Beveler is a right-angle drive I.D. clamping tool that features a push-pull clamp and release mechanism that engages and disengages easily. Ideal for beveling tubes and small pipes with a high percentage of chrome, this tool produces precision welding end preps without cutting oils and comes in pneumatic, electric, and battery powered models.

Enabling users to achieve X-ray certifiable welds without hand grinding, the Esco Ground MILLHOG Beveler is suited for tube and pipe from 0.5” I.D. to 2.25” O.D. with 0.5” thick walls and only needs a 1.5” radial clearance. It has totally sealed construction and can be used in any orientation.

New Scaled-Down Robotic Gripper Features the Same Benefits as Predecessor

Kurt Workholding’s (Minneapolis, MN) new RV24 Robotic Gripper is a two-finger parallel gripper featuring a revolutionary patent pending design that allows automated finger/end effector changes without changing the gripper body itself. Quick change jaws allow customers to improve automation efficiency, save on gripper-body expenses and create greater part-holding flexibility.

Loaded with features, the compact RV24 comes standard with integrated electronics featuring sensors that ensure fingers and parts are in place and ready for production. High-strength aluminum alloy keeps gripper weight to a minimum while a hard-coat finish reduces wear and increases life in the field. The gripper’s size allows for smaller part handling, lighter minimum clamping force and easier storage where space is a premium. It is designed to work with a range of robotic applications and performs well on cobots or smaller robots.

“When we introduced the RV36 back in 2020, we knew it would be the first in a family of robotic grippers,” said Jeff Lenz, executive vice president of proprietary products, Kurt Manufacturing. “While working with customers we determined that a smaller cobot-compatible gripper made the most sense as our next robotic automation product.”

The gripper’s double-acting piston allows for flexible clamping and unclamping force. Customers can choose from machinable aluminum or steel finger options that can be machined to work in a variety of applications. Additional finger sets are also sold separately along with finger clips for holding multiple gripper sets.

Kurt Workholding, a division of Kurt Manufacturing, designs, manufactures and assembles its machine vises and workholding technology in the USA. It sells a complete line of workholding products for the machining industry.

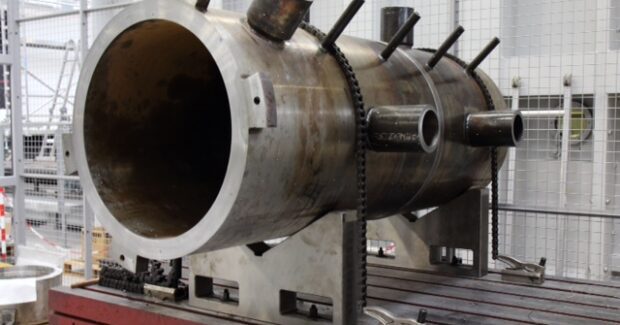

Quick Setup Workholding Solutions Save Time and Money

Lenzkes Clamping Tools (Christiansburg, VA) is known for its high-quality workholding solutions for all types of machines. Products are applicable for machine tables/platen with t-slot and/or tapped holes and feature high clamping forces ensuring quicker and safer changes. Lenzkes chain clamps provide the fastest and safest way to hold round and bulky workpieces securely in place by low torque settings. The chain clamp product is easy to adjust, which increases productivity by reducing setup time. The MQ150 and MQ160 quick release tools offer exceptional stepless, vertical and horizontal adjustment. The unique arch shaped clamping arm provides multiple options regarding clamping position. The MQ 160 provides a greater stepless horizontal adjustment due to an elongated slot in the clamping rail.

Dual Force Precision Multifunction Vises Lighter than Other Vises

Highly versatile, Palmgren’s (Naperville, IL) Dual Force Precision Multifunction Vise can be mounted on their base, bottom, either side or upright. They also can be mounted back-to-back to create a fast, easy and economical vise tombstone. As part of Palmgren’s Dual Force line of precision vises, the multifunction models are designed for precision part clamping, and are ideal for use in running production parts where datums, flatness and parallelism is important. The more than 100-year-old Palmgren is a C.H. Hanson® brand.

Automatic Tool Setter Clamps a Tool in Less Than 10 Seconds

REGO-FIX (Whitestown, IN) offers the PGU 9800, an enhanced version of its proven PGU 9500 powRgrip automatic tool setter, with integrated touchscreen controls, a quieter motor and a status display. The touch-and-swipe LCD displays the size of the current PG insert along with technology cycle counts by tool size, analytics, diagnostic codes and the machine build date.

Like the PGU 9500, the PGU 9800 clamps a tool in less than 10 seconds with up to 9 tons of clamping pressure. For convenience, the unit runs on standard 110V AC power, handles tapers including CAT, HSK, BT, CAPTO, BIG +, TC and ISO, and clamps carbide or HSS in h6 tolerance, including Weldon flat and long shank tooling.

Unlike other clamping systems that rely on heat or hydraulics, the PGU 9800 uses the mechanical properties of the holder material to generate tremendous gripping force, with TIR of less than 0.0001 (≤3 µm) and length adjustment repeatability of less than 0.0004″ (10 µm). Tools are ready to use immediately, with no wait time, loss of accuracy or shortened tool life.

The touchscreen control panel also displays full information about a customer’s PGU 9800 unit. The display enumerates cycle statistics and provides an easy-to-use digital indicator of error conditions.

The unit is available with customized wraps that feature a customer’s logo and corporate colors. A two-year warranty covers parts and labor.

Flexible Machine Loading and Unloading with New Centric Clamping Vise

SCHUNK (Morrisville, N.C.) now offers even more options in the field of automated machine loading. The TANDEM3 modular system for stationary use now has an additional component for flexible workpiece clamping with the new KRP3 centric clamping vise. With this powerhouse, even round workpieces can now be clamped automatically from the outside and inside in confined spaces. Like all stationary clamping devices from SCHUNK, it can be quickly and easily mounted on the VERO-S quick-change pallet system using console plates, which allows changes to be made as required. The clamping force block is also available in hydraulic (KRH), spring-loaded (KRF) and electric (KRE) versions. If you are still at the beginning of your journey and planning a cost-effective partial automation of your machine tool with a cobot, the new MTB application kits offer a convenient approach to automation. The grippers and power vises included are adapted for metal cutting machining and can be combined with robot-specific connections.

Subscribe to learn the latest in manufacturing.