Well Done Welding Finishes

Advancements in surface prep and finishing abrasive products ensure high-quality finishes, tool-free wheel changes and safer products that prevent breakage. Abrasives suppliers continue to collaborate and test products in the field with their customers to ensure the resulting products provide faster cuts, longer product life and reduce operator fatigue. What’s more, robotic and automated solutions provide alternatives to achieve the precise removal of a wide range of materials.

Posted: December 22, 2022

WELDING

First-of-Its-Kind Stringer Bead Brush Establishes a New Standard

Osborn (Richmond, Ind.) is once again bringing industry-leading innovation to the pipeline, welding and metal fabricating markets with its new stringer bead brush that offers twice the life and aggression of its already proven and industry-leading Four-Inch TufBrush Stringer Bead Brush. The innovative technology involving two brush sections also gives it the ability to clean both sides of a weld at the same time.

The new Honey Badger Double Stringer Bead Brush establishes a new standard in welding, as there are currently no other brushes on the market that can achieve what it can. The Honey Badger is built with two sets of wire knots on a unique face plate and nut. Because of how it’s constructed, the brush can hit both sides of the root, or hot pass, while cleaning out any slag or debris of a weld.

“We have a long history of listening to our customers and their demands, placing value on their feedback to create the best solutions and products,” said Brian Keiser, vice president of operations, Osborn. “Collaborating with you — the experts in the field — helps us drive innovation and create the products you really need.

“The Honey Badger Double Stringer Bead Brush already promises to offer a longer lifespan, a faster cut, less operator fatigue and less effort, so we’re excited to see the impact it has on our industry,” Keiser continued. “Thanks to this testing period and collaborating with specialists who use these tools, we expect to be able to further improve our final product.”

The patent-pending Honey Badger Double Stringer Bead Brush will be available to purchase this year. Osborn is the world’s leading supplier of surface treatment solutions and high-quality finishing tools for industrial and commercial applications within material finishing, deburring, cleaning, honing and surface polishing segments.

Abrasive Belt Machines Ideal for use with Coated and Non-woven Nylon Belts

The Dynastraight® Series of portable air-powered abrasive tools from Dynabrade, Inc. (Clarence, N.Y.) feature an ergonomically designed, lightweight composite housing which reduces tool vibration and is thermal-insulated to prevent cold air transmission to the operator. Specific applications of Dynastraight tools include paint and rust removal, refining before final finishing, medium and fine grain finishing and final finishing.

Ranging in availability from .4 – 1 hp, the tools are ideal for use with coated abrasive belts, abrasive impregnated non-woven nylon products, coated abrasive flap wheels, buffs and non-woven nylon belts mounted on Dynacushion® inflatable pneumatic wheels. Use the inflatable pneumatic wheel for finishing work surfaces of virtually any shape, contour or material; excellent for finishing stainless steel and other metals. The wheel conforms to the contour of the work surface.

The Dynastraight Series works on a variety of materials including stainless steel, aluminum, carbon steel, copper, brass, plastic, fiberglass, composites, wood and more. The straight-line tools feature high quality air motors ranging from 950-to-18,000 rpm. The tools also feature an adjustable speed air motor and a standard muffler, which reduces noise levels in the workplace. Made in the USA.

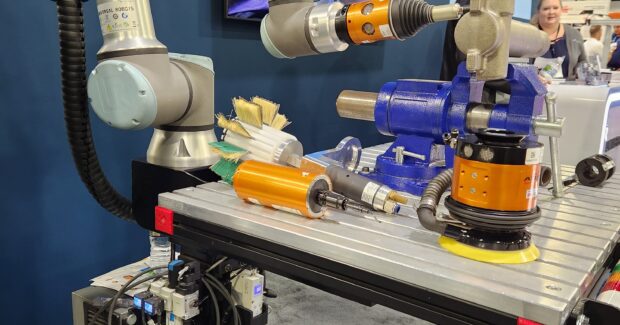

Robotic System Enables a Wide Range of Material Removal Operations

At FABTECH 2022, Kane Robotics, Inc. (Chino, CA) demonstrated in the Universal Robots booth the GRIT™ ST-X robotic system, which is ideal for sanding, grinding and finishing smaller products. It includes best-in-class hardware, customized programming and robust data solutions. The GRIT ST-X featured ATI Industrial Automation’s Universal Robots+ certified Compliant Reciprocating Tool.

The CRT-12-5 Compliant Reciprocating Tool enables a wide range of robotic material removal operations. The CRT-12-5 produces a filing motion that is uniquely compatible for precise tasks like deburring edges and removing flash from cast metal parts. It features built-in compliance, making programming easier, ensuring consistent results. The cutting force is adjustable on-the-fly so users can fine-tune the process to achieve their ideal finish and accommodate material removal from multiple features or parts.

The ATI Industrial Automation’s Compliant Reciprocating Tool utilizes widely available industrial finishing media and can be deployed in a variety of ways, which makes this tool a robust yet flexible alternative to filing by hand.

Kane Robotics automates dull and dirty processes with next-generation robotic solutions. The products are developed around a common platform designed for reliability.

Automated Surface Prep Cell Performs High-Precision Cleaning

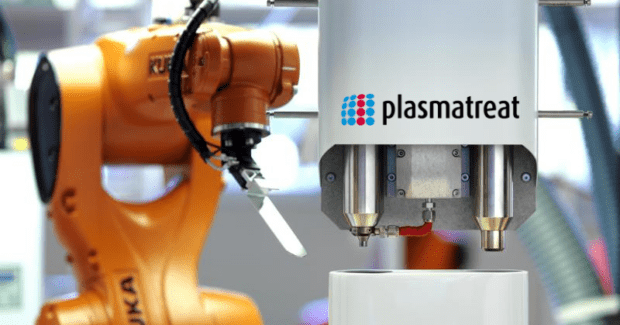

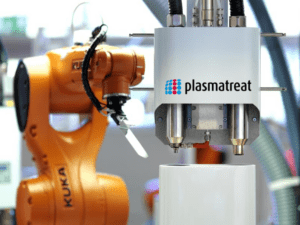

To meet ongoing demand for increased efficiency and standardization for surface bonding pretreatment solutions, KUKA Robotics (Shelby Township, MI) offers the ready2_activate surface preparation cell application with system partner Plasmatreat. The ready2_activate application was specifically developed by KUKA to be used with all standardized pretreatment using Openair-PlasmaÒ technology.

With the ready2_activate application and utilizing a KUKA KR AGILUS robot and modular platform, the Plasmatreat Openair-Plasma jet technology performs high-precision cleaning by activating or nanocoating material surfaces. Many materials, such as plastics and polymers, do not bond easily with certain types of printing or coating unless their glossy textures are pretreated. Plasmatreat’s process prepares surfaces for gluing, printing or lacquering without generating any chemical waste. The KUKA robotic motion sequence and plasma process are controlled by processors in close communication for easy integration into a production line or process.

The KR AGILUS robot is a precise, high-speed 6-axis robot that comes in a variety of variants, including extreme environments, for virtually any application requiring short cycle times, continuous repeatability and high production. This new system integration platform with KUKA robots provides simple, standardized automated solution to incorporate plasma surface treatment into a variety of production processes that require surface pretreatment.

KUKA is one of the world’s leading suppliers of intelligent automation solutions; from robots and cells to fully automated systems and their networking in markets such as automotive, electronics, metals and plastics and more.

New Cutting and Grinding Wheels for Aluminum Offer Best-in-Class Performance

Saint-Gobain Abrasives (Worcester, MA), one of the world’s largest abrasives manufacturers, has introduced the Norton for Aluminum Thin Wheels for the right angle cutting and grinding of aluminum and other non-ferrous soft metals. High quality, extra-friable and self-sharpening aluminum oxide grain and specialized bond technology results in the best cutting and grinding wheel market performance in its class. The wheels offer aggressive, fast cutting that resist loading and minimizes heat on the workpiece, providing consistent, long-lasting wheel performance.

Norton for Aluminum wheels have a range of features and benefits including a 5/8″- 11″ hub for quick, tool-free wheel changes. Helping to keep metal surfaces clean for defect-free, corrosion-free welding, the wheels have a contaminate-free bond which does not need any waxes or lubricants. Also, a double coarse layer construction adds versatility and life on applications such as back-grinding and notching.

Key markets include aluminum and metal fabrication, welding, shipbuilding, automotive and transportation, aerospace and construction. Applications include aluminum, cut-off, portable grinding, beveling, notching, smoothing welds and offhand stock removal. The new wheels are available in 1/4″ Grinding Type 27, 1/8″ Cutting/ Notching/ Grinding Type 27, .045″ Right Angle Cut-Off Types 01/41 and 27/42, and Straight Cut-Off Type 01/41.Wheels-Thin-ALU-02.

Foundry Abrasives Improve Safety and Productivity

Weiler Abrasives Group (Cresco, PA), a leading provider of abrasives, power brushes and maintenance products for surface conditioning and solutions for a variety of industries, offers a line of cups, cones and plugs with specially designed anchored mounting systems for additional safety. Tiger Type 11 cup wheels are available with industry-exclusive ceramic grain technology to deliver up to 30% faster cut-rate compared to zirconia cups. The advanced micro-structure of the ceramic grain results in extremely low specific cutting energy, providing ultra-high metal removal rates to improve productivity when grinding cast and ductile iron, cast steel and other hard-to-grind materials. Tiger cup wheels are available with multiple grain technologies and include a unique anchored nut to secure the cup in place, increasing safety and preventing product breakage.

The Tiger Type 27 depressed center grinding wheels are available in three performance tiers specifically designed for foundry applications, including Tiger Ceramic for superior cut and long life. The ability to remove 40% more material over the wheel’s life compared to zirconia products increases productivity and reduces abrasive usage. Tiger Zirc and Tiger AO grinding wheels are also available, providing cost-competitive material removal rates and extended product life.

Subscribe to learn the latest in manufacturing.