Automation + Robotics = Smart Shops

Shops of all sizes are embracing automation and robotics systems and benefiting from major productivity gains with existing staff.

Posted: January 20, 2023

The metalworking industry is on the lookout for solutions that will assist in any number of areas of manufacturing. This is particularly true when it comes to ensuring efficient production while balancing skilled labor shortages. In addition, job shops of all sizes expect those solutions to be easy-to-use, intuitive systems.

Industry suppliers continue to respond to those needs by developing the next iterations of cobots, robots, automated in-process inspection systems, digital transformation — the list goes on. As a result of partnerships with job shops and fellow suppliers, companies offer smart solutions that range from the design process to the manufacture of quality, precision parts.

New Industrial Cobot Delivers Class-leading Speed and Safety

ABB Robotics & Discrete Automation’s (Auburn Hills, MI) new SWIFTIA™CRB 1300 collaborative robot (cobot) is six times faster and five times more precise than other robots in its class. Combining class-leading speed and accuracy with expanded load handling capability of up to 11 kg, the SWIFTI CRB 1300 can be used in a variety of production and product handling applications — from machine tending and palletizing to pick-and-place and screwdriving. “Our customers are looking to robotic automation to make their processes more flexible, efficient and resilient, helping to counter labor shortages by enabling their employees to perform more value-added work,” said Andrea Cassoni, managing director for Global General Industry Robotics at ABB.

The SWIFTI CRB 1300 incorporates several features that can improve production efficiency by up to 44 percent compared to other cobots in its class. Powered by ABB’s OmniCore™ C90XT controller, it is up to five times more precise than any cobot in its class. The SWIFTI CRB 1300 prioritizes operator safety, with a safety laser scanner integrated with ABB’s SafeMove collaborative safety software. The technologies enable safe collaboration to be achieved without the space and cost associated with installing protective fencing or other physical barriers.

Smart Automation for Factory Connectivity

ANCA’s (Wixom, MI) AIMS (ANCA Integrated Manufacturing System) solution considers the factory as a single machine. Rather than separating workflow into many different elements of design, blank preparation, grinding, laser marking, washing, packing and shipment — AIMS streamlines the entire tool manufacturing process and complementary technologies. The main modules of the AIMS system include an AutoSet job preparation station; AutoLine for pallet and tool transfer; the AutoFetch robot responsible for material transfer between processes — pallet and individual tools between job preparation; and grinding and tool measurement on a ZOLLER measuring machine.

AIMS responds to common challenges in the tool manufacturing sector of labor cost and availability as well as safety and production efficiencies. Access to skilled staff and the need for elimination of simple, repeatable tasks which could be easily automated – AIMS maximizes grinders’ productivity and in general improves OEE. Integration with ERP systems to streamline workflows is also a benefit.

The principles of the AIMS system are flexibility and modularity. Systems can be tailored to customer’s needs and can be scaled from a software-based monitoring solution to a fully automated manufacturing cell.

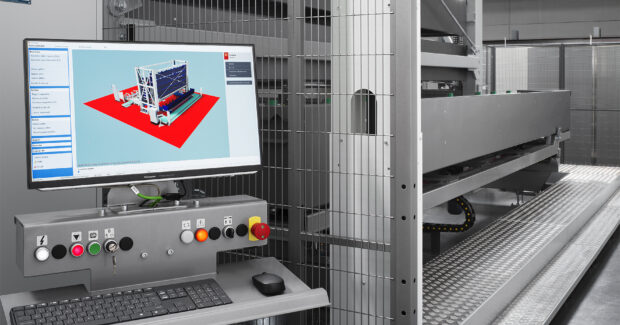

New Automated Tube Storage and Retrieval Solution

BLM Group (Novi, MI) offers new automated tube storage and retrieval solutions for integration with the company’s tube laser systems. These solutions feature special cassettes, pre-loaded with stock in a staging area, for loading directly inside the machine. The storage system automatically retrieves the correct material, quickly and safely bringing the material to the machine where it is loaded. When jobs are complete, the system will remove the used cassette with any remaining stock to be placed back into the tower. The system automatically checks the stock level and updates the warehouse management software. Automating these tasks helps to improve workplace safety and productivity by reducing the amount of downtime caused by moving raw material between jobs or restocking unused materials.

For additional flexibility, BLM Group offers a second retrieval system style for use with a central warehouse. In this style, the desired bundle is automatically extracted from the storage tower and staged near the machine in a queue for either crane or forklift loading. This system is great for customers who have older legacy machines that can’t use the automated system.

In the past, tube lasers have featured integrated bundle loading — which always required the use of overhead cranes or forklifts for loading raw material — and finished-part unloading systems. Given the variable tube specifications such as length, profile shape, automating this process is more difficult than in a 2D application. Additionally, maintaining a stable tube position during movements and separating the tubes is challenging. Despite these issues and some potential limitations, automating the storage and retrieval functions will increase manufacturing efficiency for tubular components, as well as improving workplace safety.

Cutting-edge Multiple Robot Motion Software

The KUKA.RoboTeam Coordinated Motion Software synchronizes motion start and motion time of two or more robots for geometric coupling of multiple robots and state-of-the-art production. KUKA’s (Shelby Township, MI) software transfers decision making and responsibility of conventional, centralized PLC functions directly to the robot group for autonomous group execution. Synchronization commands are programmed in the robot programming interface with modifications to the path or velocity of each robot in the group that have an immediate effect on all other robots in the group. All safety-relevant signals are communicated within the group, and an emergency stop of any single robot triggers synchronized, path-maintaining braking of the entire robot group.

Geometrically coupled robots provide a flexible solution for all handling tasks in which heavy loads need to be transferred and ensure process-optimized positioning even of pliant workpieces. This function can also be used for the application of parallel processes alongside the transfer of materials.

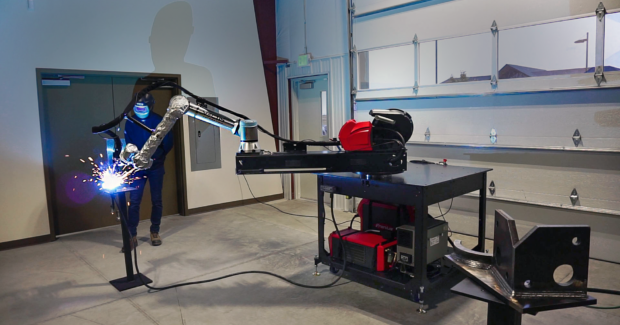

Cobot Welders Grow Up

It is time to refresh your expectations about collaborative robot-powered welding systems, according to Universal Robots USA Inc. (Ann Arbor, MI). He shared the following thoughts about the evolution of cobots.

Collaborative welding automation has been successfully deployed on thousands of industrial welding applications. It is proven technology that reduces waste and rework, improves ergonomics, and boosts welding productivity and throughput.

The first wave of collaborative welding systems was designed to tackle low hanging fruit; light and simple, predominantly MIG-based welding applications that don’t require water cooling or other advanced features. Within these limitations, the first wave of collaborative welders performs exceptionally well. Thanks to their low total cost of ownership, built in safety features, small footprint, fast return on investment, and ease of use, the first wave of cobot-powered welding systems continues to be a popular choice.

In the past few years, a new wave of collaborative welding systems has emerged. This second wave of automated welding automation delivers so much more in terms of functionality, usability, range, and power than its popular predecessors, that it’s fair to talk about a generational leap in capability.

For example, early cobot welding systems were air-cooled and couldn’t handle the demands of high amp rated welding applications. Many of the latest systems have water-cooled torches and can handle such tasks with ease.

Similarly, TIG welding, hardfacing and plasma cutting are now capabilities of some of the new wave of cobot welders. Complex cuts on 3D shapes, multi-pass welding, thru-arc seam tracking, and touch sensing capabilities enable cobot-powered automated welding applications that just weren’t possible a few years ago.

At the same time, cobots capable of handling larger payloads (20 kg/44.1 pounds) and with longer reach (1750 mm/68.9 in.) will soon arrive on the market to provide a further boost to capabilities. New accessories keep arriving too; from rotational range extenders to cobot-controlled rotary tables that allow users to create separate load and weld stations on a single cobot-powered system.

Available in ready out-of-the box welding application kits that contain all the hardware and software required to quickly set up a safe and effective welding automation cell — whether your welding source of choice is Miller, Lincoln or Fronius.

And, even though today’s cobot welding systems are vastly more capable than their predecessors, they are also significantly easier to operate thanks to user-friendly programming methods and interfaces, such as hand-guiding and smartphone apps. — By Joe Campbell, senior manager, Strategic Marketing & Applications Development at Universal Robots A/S.

Software Boosts Productivity in Connected Manufacturing

TRUMPF Inc.’s (Farmington, CT) new Oseon software package for production scheduling and control enables companies to create significantly leaner production processes and make major gains in productivity. The software includes new options for managing the transportation of materials in a flexible and automated fashion.

Oseon also offers production workers a clear display of all relevant production data directly within their work environment. “As well as reducing downtime and non-productive time, the software also makes a better use of machine capacity, makes life easier for employees and results in productivity gains,” said TRUMPF Inc.’s Software Solutions Sales Manager Claudio Santopietro. “And the software is easy to deploy in any sector thanks to its open interfaces.”

The software allows users to fully automate the flow of materials on the shop floor, potentially eliminating the need to invest in a large-scale storage system. “Oseon lets users synchronize material flow with their production schedule, so they can respond even faster and more flexibly to unexpected events such as rush orders, as well as processing more orders in less time,” Santopietro said. Once the user has loaded their production schedule into Oseon, the software takes over the task of managing many of the factory’s logistics processes. It receives continuous process data updates from all the production machinery. In addition to the data from the production schedule and machines, the software also holds information on batches, material stocks, the locations of each cart and trolley, and the parts that are required on the shop floor.

Staff can see data on the manufacturing process and on upstream and downstream activities in one intuitive display – no paper, no switching between different media, and no need to leave the shop floor.

Oseon allows sheet-metal fabricators to boost the competitiveness of their production activities. The software can be used on shop floors where digital connectivity is still in its infancy as well as in fully-fledged smart factories. Open interfaces mean the software also enables the integration of machines from other suppliers.

Laser Cutting System and Linear Loading Automation Offer Unmatched Productivity

AMADA AMERICA, INC.’s (Buena Park, CA) 12kW REGIUS 3015 AJ fiber laser cutting system is engineered with the world’s fastest 3-axis linear drive technology and autonomous features. Intelligent features and functions are integrated into the machine to enable continual self-monitoring. The REGIUS Series comes in 6kW, 9kW and 12kW fiber laser cutting systems.

This innovative laser cutting system automatically adjusts machine and process parameters according to the needs of the current cutting operation. Autonomous features enable REGIUS to achieve maximum productivity and cost-effective processing while simplifying machine operation and optimizing utilization. Features include lens monitoring, collision recovery, automatic head recovery, nozzle change and centering. The i-Cas allows operators to setup and cut on remnant materials safely and easily. Upward opening doors provide easy access to the entire laser bed.

Pairing the REGIUS with AMS 3015 LL (Linear Loading) automation further enhances productivity while maximizing the use of valuable floor space. The modules feature a symmetrical design that allow them to be placed at either the front or rear side of a laser cutting system. The 3.0-by-1.5-meter size of the system accommodates 5’-by-10’ sheets of material.

“Flying Motion” System Expands Features

Beckhoff Automation (Savage, MN) has created new possibilities in adaptive automation by expanding the functionality of the XPlanar “flying motion” system. The XPlanar solution can handle more products with even more flexibility through new mover identification, movers for two lanes of traffic on one tile, rectangular movers and mover coupling for higher payloads. XPlanar now provides greater traceability through ID technology integrated into the mover bumper. The ID functionality enables unique identification of XPlanar movers by reading the mover’s individual serial number. The ID bumper is easy to mount or retrofit on movers already in the field, and it requires no additional hardware. This solution makes it possible to seamlessly track movers and the products they carry – even after system shutdown and restart.

A third new variant of the XPlanar is the AMP4350 rectangular mover, which measures 155-by-235 mm and supports payloads of up to 3 kg. By adding a second row of tiles to the XPlanar base, the APM4350 rectangular mover enables up to three lanes of transport for longer products, further increasing adaptive automation capabilities, and transporting payloads up to 4.2 kg. Elaborate workpiece carriers and attached tooling can also help meet specific application requirements. Using an adapter, movers can be connected, and the payload increases linearly. Coupling four APM4550 movers results in a maximum payload of approximately 14.8 kg.

Affordable Machine Pairs with Cobot for Unattended Production

Mazak Corp.’s (Florence, KY) VC-Ez 20 Vertical Machining Center is an automation-ready machine featuring a 40-taper spindle and space-saving design (26.5% floor space savings over other models) that offers affordability, with a full range of spindle, auto tool changer and chip/coolant management options. A generous work area eases the loading and unloading of workpieces and tools, while a fast traverse rate of 1,654 ipm (42 m/min) in the X, Y and Z axes enables higher throughput. It accommodates maximum workpiece sizes of 49.21″ long, 19.37″ wide and 22.4″ tall (1250 mm-x-490 mm-x-570 mm) and weights up to 2,204 pounds (1,000 kg).

The VC-Ez 20 is designed for standard or customized automation solutions for unattended production and productivity, including cobot installations such as Mazak Automation Systems’ CC-10 and CC-16 Cobot System models. The CC-10 system uses a FANUC CRX-10iA/L with 10 kg payload capacity, while the CC-16 is built around a Universal Robots UR16e platform with a 16 kg payload capacity. Both cobot models come with three available grip systems and use an area scanner with limited fixed fencing for fully collaborative human-robot workflows.

Cobot-controlled Rotary Table Enables the Weldment of Larger and Complex Parts

Hirebotics (Nashville, TN) and partner Kinetic Technologies LLC, have launched the RT1, a new cobot-controlled rotary table designed to maximize welding capacity. “The need for this system is two-fold,” said Rob Goldiez, co-founder of Hirebotics. “RT1 gives customers the ability to rotate the part to the front and back for welding. Secondly, it gives users with high volume production the ability to have separate load and weld stations; loading a part on one side while the cobot is welding on the other, increasing arc on time and throughput.” The Hirebotics Cobot Welder is equipped with the new indexing table, RT1 from Kinetic, and excels on handling hard-to-reach joints and products such as large frames and welded steel boxes where a cobot on a single table cannot reach fully across the part. Users can control the A/B position directly within Hirebotics’ Cobot Welder’s Beacon cloud-based software platform.

Intuitive CNC Controller for Automated Plasma and Oxy-fuel Cutting

This year, ESAB Cutting Systems (North Bethesda, MD) will begin offering the Vision T6 CNC for automated plasma and oxy-fuel cutting machines to help operators become productive with minimal training, plus add new functions that increase productivity and quality. “Customers asked us to help reduce the CNC controller learning curve so that their new employees could become productive with minimal training,” said Steve Zlotnicki, global product manager, ESAB Cutting Systems. The Vision T6 is available for both new machines and retrofit applications, and supports ESAB’s wide range of cutting, beveling, and marking tools, including the DMX Plasma Beveler.

The Vision T6 connects with Columbus®, ESAB’s industry-leading CAD/CAM programming and nesting software, now part of the InduSuite family of software products. With Vision T6’s new plate and part awareness function, operators do not need to physically align the plate. Instead, the operator can jog the machine to the plate corners or pick points along a plate remnant, even if it’s an irregular shape. The controller then knows the exact shape, size and location of the plate on the table displayed graphically for operators to see. Operators can then choose a program and simply drag and drop the part or parts nest onto the plate and it will snap to the correct position. The Vision T6 controller lines up the plate, ensuring accuracy without the need for a dry run.

Cobots Expand Capabilities and Overcome Labor Issues

FANUC America Corp.’s (Rochester Hills, MI) CRX-25iA welding cobot offers a 25 kg payload and 1,889 mm reach. Users teach weld joints using hand guidance or a tablet interface with drag and drop icons. The easy-to-use CRX welding cobots support FANUC’s advanced features including iRVision®, Torch Angle Control, Touch Sensing and Thru Arc Seam Tracking.

Last year, FANUC expanded its popular series of CRX cobots with the new CRX-5iA, CRX-20iA/L and CRX-25iA. With a total of 11 CR and CRX cobot model variations, FANUC has a cobot to handle products ranging from 4-to-35 kg in applications such as welding, inspection, machine load/unload, packing, palletizing, sanding and more. “Our CRX cobots are designed for every type of manufacturer — small or large — looking to expand their capabilities and overcome labor issues,” said Eric Potter, general manager of FANUC America’s General Industries and Automotive engineering groups.

The CRX cobots can detect external forces in the workspace, stopping safely when making contact with a person or object. The CRX works safely alongside people without the need for expensive guarding.

Automated MIG Welding System Provides Greater Deposition Rates

Miller Electric Mfg. LLC (Appleton, WI), Hobart Filler Metals and Tregaskiss have released the Hercules™ single-wire, high-deposition, automated MIG welding system. The Hercules system significantly boosts welding productivity rates without the expense of adding more automation welding cells.

The system delivers a gain of up to 30% or more in deposition rates and corresponding productivity with no loss of weld quality. Even operations that have optimized their processes and consider themselves at the forefront of high-deposition-rate welding can benefit from the Hercules system.

The Hercules welding system is ideal for medium to large manufacturing operations with robotic welding, specifically for those with long welds in the flat and horizontal welding positions. The system has been in a soft introduction phase with targeted Miller customers for several years, and Miller has worked with those customers to integrate the system. “That valued relationship and feedback made us aware of where the system was lacking and therefore, we were able to revise the process to make it more reliable and robust,” said Seth Perrin, advanced welding product specialist at Miller.

The Hercules MIG welding system combines a Miller power source and wire-feed technology, a Tregaskiss torch and a specialized Hobart metal-cored wire.

A Flexible Human-Collaborative Workcell for Robotic Welding

Designed for human-collaborative (HC) interaction, the highly flexible Yaskawa Motoman (Dayton, OH) ArcWorld® HC is a complete robotic welding solution for the fabrication of small- to medium-size parts. Ideal for replacing or supplementing manual weld processes, such as pre-assembly before welding in larger robotic workcells, this pre-engineered mobile cart system is well-suited for high-mix, low-volume production.

Joining Yaskawa’s proven line of ArcWorld welding workcells, this portable job shop comes complete with a 1,200 mm-by-2,400 mm perforated fixture table, a single human-collaborative HC10DTP robot, retractable arc curtain, built-in exhaust hood, a compatible Miller®, Lincoln Electric, SKS, OTC or Fronius power supply, a 14-guage metal tool board, tool balancer and debris tray. A 120 VAC 20-amp electrical extension outlet and 120 psi air connection are provided for common welding tools. Wire spool and shield gas bottle holders are optional.

The HC10DTP features power and force limiting technology for safe operation and hand-guided teaching for easy programming without a pendant. Offering a 1,379 mm maximum working range and a 10 kg payload capacity, the HC10DTP can process parts up to 500 H-by-2,000 W-by-800 D mm. Its IP67 rating enables welding without additional coverings or equipment. Fast air cut speeds (500 mm/s) are easily achieved with arc curtain closed or they can be maintained at collaborative speed (200 mm/s) when the curtain is open. Risk assessment provided for assured, safe design.

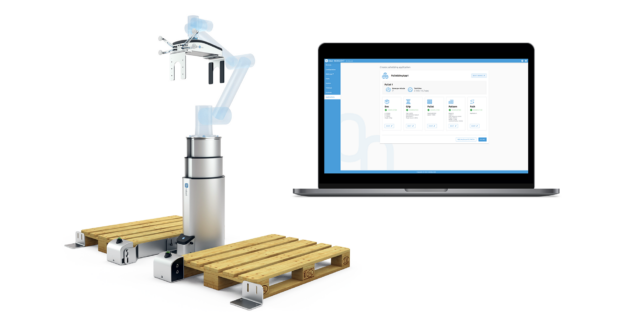

Automated Palletizing Hardware and Software Solution

The OnRobot (Odense, Denmark) Palletizer combines affordability, performance and fast integration with a small footprint to deliver flexible palletizing automation to companies of all sizes. OnRobot’s application-first approach to collaborative automation allows users to choose a palletizing system that works for their specific application needs thanks to its space saving footprint, and ability to handle many different types of boxes, packages, patterns, pallets and stacking heights. Compatible with cobots and light industrial robots from the Doosan, FANUC, OMRON, Techman and Universal Robots brands, the Palletizer is available as a complete out-of-the-box system or as individual components to create a mix-and-match solution.

One of the Palletizer’s components is OnRobot 2FGP20, a versatile, electric palletizing gripper with a 20 kg payload and customizable arms that can handle standard cardboard boxes as well as open boxes and shelf-ready products, while also handling slip sheets without changing the gripper or requiring additional handling; no external air supply is required.

Another component is the Lift100, an elevator with a total payload of 100 kg that provides a 7th axis for cobot and lightweight industrial robot brands; its TÜV-certified stop-functionality facilitates safe and effective collaborative deployments.

“By making affordable collaborative automation available to companies of all sizes and technology skill levels, OnRobot is breaking down the global barriers to adoption while building a unique ‘One Stop Shop’ designed to meet all the automation and business requirements of manufacturing and warehouse companies,” said Enrico Krog Iversen, CEO of OnRobot.

New Cobot with Extended Range

Vectis Automation LLC (Loveland, CO) offers the new Park’N’Arc; a “diving board” rotational range extender that allows for the base of the cobot to be manually moved to various locations. “Compared to a short linear track, the Park’N’Arc is an improved design for increasing range as the cobot base can be translated nearly eight feet in a linear direction while maintaining simplicity, robust cable management, and portability,” said Josh Pawley, co-founder of Vectis Automation.

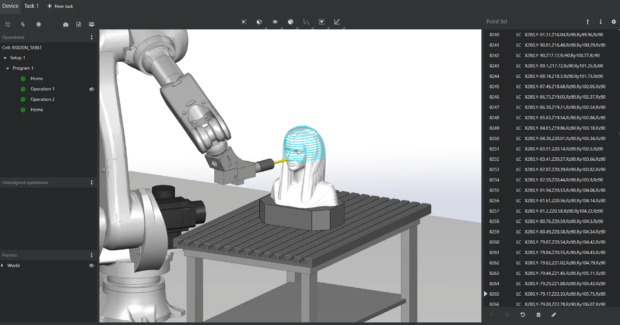

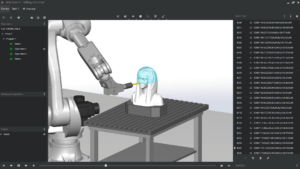

Software Bridges the gap Between CAD/CAM and Robotics

Last year, Hypertherm Associates (Hanover, N.H.) released a major version update and new name for its Robotmaster® offline programming software for robots: Robotmaster 2023. It bridges the gap between CAD/CAM and robotics by enabling seamless integration between a user’s chosen CAD/CAM software and Robotmaster. This automatic integration eliminates the need to import and sync data for a 75% reduction in programming time. It also eliminates the programming errors that can happen when using a manual process.

The new Robotmaster version allows for the creation of libraries that provide a more convenient way to store and re-use robotic cell components. Users can easily preview and select components within the library and save modified or proprietary components for later use. This reduces the cost of building and editing a cell by approximately 50%.

Software developers have also added several customer-driven improvements. Improvements support the latest CAD formats, and include enhancements to the CAM modules, UI (user interface), and UX (user experience) to create trajectories and further improve programming.

Subscribe to learn the latest in manufacturing.