Precise Press Brakes Achieve Perfect Bends

Innovative technologies and updated features to press brakes assist shops in doing more in a challenging labor environment.

Posted: January 17, 2023

High-precision electric press brakes ensure shops will meet their production goals with fewer pain points. User-friendly equipment means short training cycles so companies can start producing immediately with both long term and less experienced workers. And automation enables decreases in production time, supports a variety of bends, and the efficient production of high-mix, low-volume parts. Enhancements in software and controls create even more efficiencies in the process.

The Latest in Servo Press Control Technology

AIDA-America Corp.’s (Dayton, OH) exclusive Allen-Bradley based servo press control, the latest in servo press control technology, works with servo presses ranging from 315–to-3,500 tons. This fully operational and interactive 19-inch PC touch screen control includes direct access to a PDF of the press manual and display of actual and virtual crank angles.

AIDA is a global leader in the design, manufacture, sale, service and support, refurbishment, and modernization of metal stamping presses and metal forming automation equipment. AIDA servo and mechanical stamping presses range in capacity from 30-to-4,000 tons, from 1-to-1,500 strokes per minute, from gap frame to straightside, high speed to cold forging, transfer and progressive die, material handling and coil feeding equipment.

Eco-Friendly High-Speed Electric Press Brake with ATC

AMADA AMERICA, INC.’s (Buena Park, CA) EGB 6020 ATCe is a high-speed electric press brake with automatic tool changer. In its ongoing commitment to the development of eco-friendly manufacturing solutions that ensure maximum productivity, AMADA recently introduced the EGB 6020 ATCe to North America.

This innovative electric press brake greatly reduces power consumption while providing automated tool setup, repeatable bending accuracy, and eliminating gauging errors and part locating fixtures. The EGB is ideally suited for precise processing of high-mix, low-volume parts, even if the operator lacks experience.

The new AMNC 4ie control provides easy, efficient operation for operators of all skill levels. It allows voice commands to request and change bend information. A backgauge camera connects to an HMI tablet and AMNC 4ie to ensure the correct bend position. The HMI tablet links with the control to display bend information above the bed.

The EGB features a 3-axis backgauge to ensure stable positioning of asymmetrical workpieces. The Bi-S II automatically measures and corrects the angle up to 85% faster than Bi-S. An automatic foot pedal slides to the next bending position, which improves efficiency.

The ATC will load the most complex tool layouts within minutes and is ideal for variable lot sizes and the seamless introduction of rush jobs.

High-precision Electric Press Brake Offers High Productivity

The BLM Group’s (Novi, MI) E-Series ProBend press brake is available in sizes from 44-to-276-ton models, which are capable of handling bending lengths of 4’-to-17’. These high-precision press brakes offer reliability, high productivity, and are a perfect complement to the company’s flat sheet lasers.

The direct-drive design of this E-Series ProBend press brake features a ball screw directly connected to the torque motor, eliminating gear boxes and belts for fewer moving components. This precision Y1/Y2 press brake with positioning and repeatability of ±0.0001″ is energy efficient, provides noise and maintenance-free operation as well as extremely fast approach, bending and ram return speeds. The E-Series comes standard with a substantial amount of stroke and open height compared to industry standards, benefitting deep box or special forming needs. Built for optimum accuracy and high speeds on all 6-axes, the E-Series’ CNC-controlled backgauge meets the demands of the most complex sheet metal applications for high-production manufacturing.

The ProBend comes with a 21.5” touchscreen console, enabling graphical or direct mode programming directly on the machine or offline. The console includes integrated views for various OLP software applications. The software automatically generates the part program from the imported CAD model and calculates the optimal bend sequence, stop positions and tooling setup. A complete bending simulation, with automatic validations and checks, allows the user to verify the entire bending cycle and begin producing parts, correctly, from the start.

www.blmgroup.com

All-electric Actuation on Hot Forming and SPF Presses

Beckwood Press Co. (Fenton, MO), a leading manufacturer of hydraulic and servo presses, hydroforming machines, automation systems, and precision forming equipment is now offering all-electric linear servo actuators on any hot forming or superplastic forming (SPF) presses up to 500 tons.

Utilizing Beckwood’s patented LSP™ technology, new hot forming and SPF presses will have an all-electric option that eliminates the need for traditional fluid power systems. Additionally, existing hot forming presses can be retrofitted with linear servo actuators to reap the same benefits of a new servo machine at a fraction of the cost.

Because LSP systems are fully electric, users will experience a simplistic design with up to 80% fewer components than hydraulic presses. Eliminating the hydraulic power units and associated components make these systems safer, quieter, more efficient, and free of leaks — eliminating the risk for part contamination due to pressurized oil. By reducing the number of moving components, electro-mechanical presses are also easy to set up, maintain and troubleshoot. In fact, Beckwood LSP presses run for millions of cycles before maintenance is required.

Tonnage monitoring and overload protection are standard on these machines, and extreme bed-to-ram parallelism is a byproduct of the technology. The intuitive programming and cycle parameters offer the highest degree of flexibility in configuring speeds, pressures, positions, and recipe creation. The programming infrastructure offers full control with strict part traceability while monitoring key components to ensure system health and part quality.

New Press Brake Features More Options, is Faster and More Precise

Bystronic Inc.’s (Hoffman Estates, IL) ByBend Smart press brake increases the flexibility, and in particular, the speed of bending. Thanks to its numerous functions and options the new machine offers bending technology at an attractive price. One of the ByBend Smart’s flexibility-enhancing features is the Daylight and Stroke Expansion, which is available with the purchase of a new machine. It extends the daylight and stroke from 18.9 inches to 22.9 inches. The additional 3.94 inches boosts the ByBend Smart’s flexibility by as much as 30% because it can use taller tools, enabling users to produce parts with taller bending sides, which is useful when bending boxes and drawers.

The Efficiency Booster option increases not only the bending speed, but also the ram retract speed by up to 20% over conventional ram retract speeds. With the Energy Saver option, the machine’s main drive is only active when the machine is in operation, reducing energy consumption by 40%.

The Fast Bend M Safety System is a high-precision laser sensor that allows the control to reduce the upper beam’s speed from up to 7.0 inch per second (rapid movement speed) to 0.74 inch per second (bending speed) just before reaching the metal sheet. The laser safety system functions like an intelligent brake assistant that permits the machine to move at a higher speed for longer. This offers users a speed advantage of up to 30%. Other options include the Electric Lifting Aid and ByVision Bending. The Active Hydraulic Crowning feature ensures high-precision air bending results.

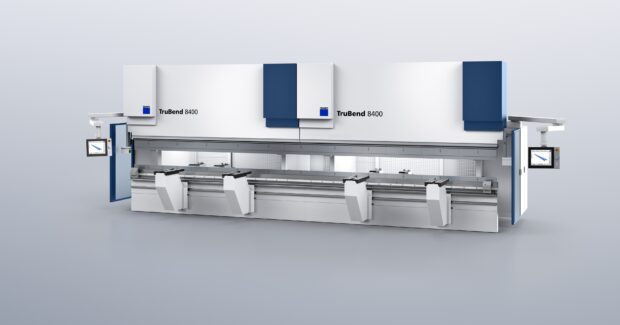

Two in One: Tandem Press Brakes

The TRUMPF Inc. (Farmington, CT) TruBend Series 8000 press brakes are already well known for their size, precision and productivity, but now, the TruBend machine can deliver twice the performance in a tandem version. “Using two machines as one doubles the bending length to more than 20 feet, while also doubling the press force,” said Roger Michaud, product manager for stand-alone TruBend, TruPunch and TruMatic at TRUMPF Inc. “In other words, users can achieve longer bend lengths and can increase part variety yet maintain the flexibility to run shorter parts separately on either machine.”

The tandem version comes as standard with a C-frame with a throat depth of 24 inches and a maximum distance between table and press beam of 32 inches. This, combined with the fact that the table width is a mere 5.5 inches despite the enormous bending forces, further increases bending flexibility and part variety. Of course, each machine can also be operated individually, for double the capacity with less setup work.

For safe operation in stand-alone mode, the two machines are separated from each other at the push of a button by a protective door. In tandem operation, the door moves back automatically, so that bending can take place along the entire length. To ensure maximum process reliability, the BendGuard safety systems of the two individual machines are connected to one another, so the entire bending length is directly under control on the tandem machine, enabling rapid speed even in connected operation.

The TruBend Series 8000 tandem version enables lower tool offset (I-axis) along the entire bending length. This allows a great variety of different bends, and also folds, using the same combination of upper and lower tools. The number of tool changes decreases, while productivity and part variety are both increased.

For TRUMPF bending machines in the 8000 Series weighing more than 600 tons, the ToolShuttle has room for up to 28 upper and 32 lower tool compartments — that adds up to storage space for more than 196 feet of tools. Easy transportation of heavy tools is possible with the intelligent transfer unit, where tools are brought to the bending machine via a moveable transfer unit with three tool holders at the top and three tool holders at the bottom.

New and Powerful Features Added to Press Automation Controller

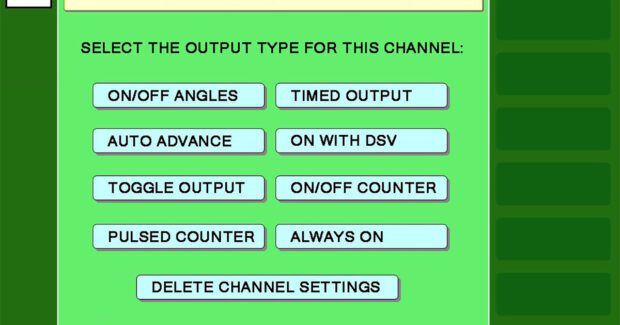

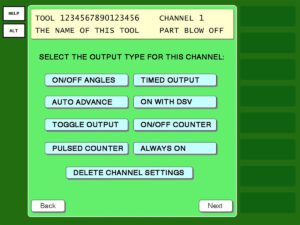

For a connection to a smarter factory the latest functionality in Wintriss Controls Group’s (Acton, MA) SmartPAC PRO gives fabricators and metal formers efficient and easy-to-use tools. Wintriss has developed the world’s most advanced Programmable Limit Switch (PLS) — the new ProCamPAC PRO, for its flagship SmartPAC PRO Press Automation Controller. The new PLS includes counter driven outputs that operate only on specified strokes to precisely control gagging operations, new asymmetrical toggle outputs for controlling complex configurable tooling, and additional timed outputs for even greater versatility.

New features include a Toggle Cam Output, an On/Off Counter Cam Output, a Pulsed Counter Cam Output, and Channel Always on Cam Output. The ProCamPAC PRO PLS also features a unique Triggered Cam Output, which actuates a precision one-time cam timing signal based on a preset trigger such as an external input from ancillary equipment, an extended period of machine idle time or a job change.

The new Advanced DiProPAC available on the SmartPAC PRO Press Automation Controller boasts more than 10 new capabilities for even greater die protection for presses. Highlights include a new customizable green sensor type called Green Flex™ that combines all the elements of the other green sensor types. This sensor monitors intermittent events such as gagging operations, and also has a function for the precise monitoring of events that need to occur multiple times per press cycle.

Subscribe to learn the latest in manufacturing.