Safe and Sturdy Lifting Solutions Boost Throughput

Make the most of forklift, crane and hoist solutions and safely increase your shop’s maneuvers and operations.

Posted: January 17, 2023

Sturdy platforms, innovative sensors and the ability to choose options and adjust features based on your shop’s needs are among the advantages of lifting material handling solutions. What’s more, durable and ergonomic designs ensure operators are comfortable for their entire shifts.

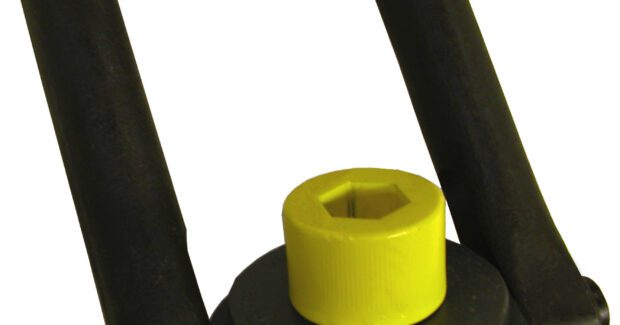

Corrosion Resistance Hoist Rings Come in a Variety of Thread Sizes

Actek Manufacturing & Engineering (City of Industry, CA) is your source for safe and easy lifting solutions, including hoists. The company maintains the largest inventory of hoist rings anywhere and offers same-day shipments. Actek offers a wide variety of hoist rings, including: deep-forged hoist rings; forged-steel plate swivel hoist rings; side-load hoist rings; hoist ring kits; and round-based swivel and pivot hoist rings.

The hoist rings can be supplied with either a shorter or longer bolt length. They come in a variety thread sizes, as well as corrosion resistance such as stainless steel, and alloy rings that can be electroless nickel plated, cadmium plated and zinc plated. The company’s hoist rings can also be custom designed to meet specific needs.

Actek manufactures top-quality products and is ISO 9001:2015 registered. The hoist rings are 200% proof-load tested and come with a certificate. The hoist rings also feature individual serial numbers for better traceability.

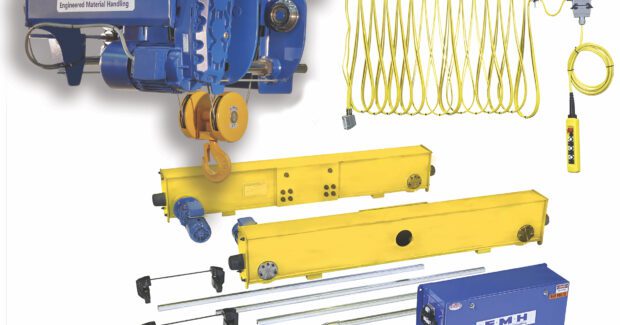

New Crane Kits Enhance Trolley Adjustment

Engineered Material Handling (EMH) (Valley City, OH) makes it easier to design, manufacture and install your own crane. By integrating the new EMH EG Series Hoist, users can count on more capability, including enhanced trolley adjustment. The new G-Series Crane Kits also include all the quality components customers need to install EMH ZLW Double Girder Top Running Cranes, ELV Single Girder Top Running Cranes, DLV Single Girder Cranes, and EDL Single Girder (low headroom) Cranes under Running Cranes.

Each kit includes the EG Series Hoist with 20 feet of lift and a lifting speed of 16/2.6 FPM with trolley speeds at 65 FPM VFD (optional lifts and speeds available); end trucks with a travel speed of 120 FPM (VFD) complete with mounting plates, bolts and bumpers (single and two-speed drives also available); trolley tow arms with pipe clamps to be cut by the builder, bolted or welded to the trolley; a complete trolley and sliding push button Festoon System with all required mounting hardware (cables are pre-wired to quick disconnect plugs, Festoon trolley is already attached to cables); bridge conductor cables pre-wired to quick disconnect plugs; trolley end stops, and detailed engineering for bridge construction and crane assembly, including two sets of maintenance manuals.

The bridge control panel is comprised of lockable fused mainline disconnect mainline fuse, mechanical and electrical interlocking contractors and motor protection, and power and control connections pre-wired through terminal strips to disconnect plugs. The panel is mounted in a NEMA-12 enclosure. All components are based on a 480 3-60 power supply. For other voltages, contact EMH.

Configurable Lift Truck Platform Maximizes Performance

Hyster Co. (Greenville, N.C.) has released the first models built on its all-new A Series platform, the award-winning Hyster H40-70A series. These 4,000-to-7,000-pound capacity lift trucks offer world-class ergonomics, low total cost of ownership and safety features designed to bolster confidence and productivity, including the innovative Dynamic Stability System (DSS).

The A Series is a new line of forklift trucks manufactured using the company’s A+ Logic design philosophy. A+ Logic is a scalable approach that begins with the strong base of the A Series truck platform and allows customers to choose the options they need from a fully integrated set of scalable and adjustable features based on their unique application.

“We developed A+ Logic because no two customers face identical challenges and meeting their needs means building the truck around them – not a generic, off-the-shelf solution,” said John Santiago, director, Product Planning and Solutions, Hyster.

Options ensure the H40-70A delivers the capability operations required while protecting budgets. Durable components and extended service intervals help further control maintenance spend and bolster reliability and uptime.

The A Series also offers robust standard features, such as DSS sensors, which when they detect the truck exceeding designated thresholds, they automatically implement measures such as limiting truck speed and hydraulic function to help minimize the risk of forward and sideways tip-overs. The H40-70A is also designed with high levels of visibility and comfort to equip operators for optimal performance all shift long.

Lithium-Iron Forklifts Available for Indoor and Outdoor Applications

NOBLELIFT® North America’s (Des Plaines, IL) Four Wheel Lithium-Iron Phosphate (LiFe4OP) forklifts are highly efficient, durable forklifts. The forklifts come in models FE4P50Q (5,000 lb. capacity), FE4P60Q (6,000 lb. capacity) and FE4P70Q (7,000 lb. capacity). The forklifts have a 10 year or 20,000 hours warranty on the lithium-ion battery. The batteries fully charge in two-to-three hours; no battery changes are necessary. Lithium-ion batteries have a 3x longer lifespan than lead acid batteries.

The forklift’s mast system, front/rear axles and chassis are engineered to be tough like an internal combustion engine forklift, but with all the advantages of lithium-iron. AC drive technology is used to achieve high performance with low operating and maintenance costs.

The large, ergonomic cab and user-friendly design ensures operator comfort throughout the entire work shift. Deluxe suspension, fully adjustable seat reduces vibration to the driver to effectively reduce driver fatigue. Ergonomic U-shaped steering wheel with knob, together with hydraulic controls, provide comfortable and effortless operation.

Other features include intelligent buffering when descending to the ground, effectively protecting the ground and cargo from damage. The drive system’s horizontal fan-shaped axle and large transmission, coupled with the battery location and long wheelbase (67 inches), provide superior stability. The lifting motor location allows the truck to work in applications where water is on the ground.

Subscribe to learn the latest in manufacturing.