Tooling Company Fulfills Customer Demand with New and In-Stock Products

CERATIZIT offers three advanced tooling solutions that are in-stock and ready for immediate delivery; includes the EcoCut Series, and the new PolyClamp Verso and MaxiLock-N.

Posted: February 22, 2023

To ensure customers receive the tooling they need as quickly and possible, CERATIZIT offers three advanced tooling solutions that are in-stock and ready for immediate delivery. Among the company’s latest UP2DATE product developments, these innovative solutions include enhancements to the popular EcoCut Series of indexable inserts, the new PolyClamp Verso universal part clamping system and new MaxiLock-N turning toolholders that incorporate the company’s DirectCooling technology.

Turn and drill ISO-P steels with ease

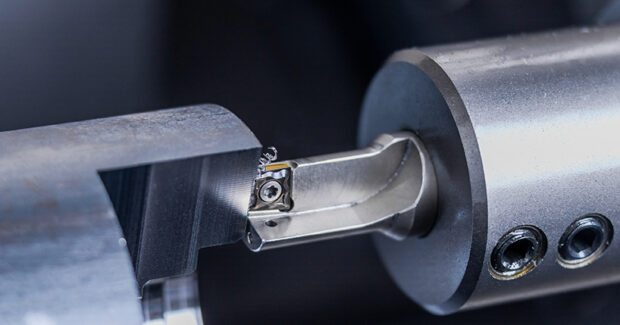

To overcome the challenges of turning and drilling steels, CERATIZIT has updated its classic EcoCut to the new EcoCut-P, and extensive tests have shown that the new inserts achieve 15% greater performance than the predecessor models. With the company’s special DRAGONSKIN coating for ISO-P materials, the inserts increase tool life and reduce machining time – thanks to the coating’s optimised layer structure.

The coating’s mechanical post-treatment induces a unique state of residual stress in the layer surface, which in turn increases process security. The DRAGONSKIN grade CTCP425-P with advanced AL2O3-TiN CVD coating is particularly well suited for when uninterrupted cuts are required. It delivers excellent wear resistance even at increased cutting speeds.

When it comes to general steel machining with interrupted cutting, the AL2O3-TiN CVD DRAGONSKIN grade CTCP435-P excels in poor machining conditions and in all applications where a high degree of toughness is required.

Flexible clamping for multi-axis machines

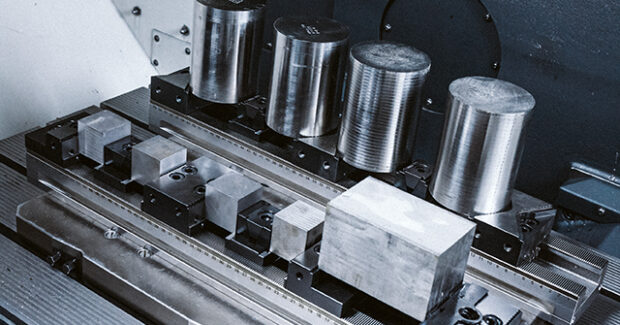

Featuring universal multiple vices, the PolyClamp Verso from CERATIZIT is ideal for use in 3-, 4- or 5-axis machines, where it easily clamps all part variants. The system’s jaws are slimmed down for this purpose while allowing even more jaws to be clamped per base rail for clamping larger unmachined or finished parts.

A scale lasered onto the centric vice is a further benefit when it comes to handling. It allows the jaws to be positioned evenly and precisely on the rail, in accordance with requirements.

The PolyClamp Verso is equipped with a quick jaw change system as standard. Using just two screws, the fixed and adjustable jaws are released, removed upwards or repositioned. This significantly reduces setup times because each jaw is individually removable without having to dismantle the others.

Precision targeted coolant extends tool life

Complementing CERATIZIT’s DirectCooling product range, the MaxiLock-N turning tool holders incorporate two internal coolant holes that aim coolant directly at the cutting edge to prevent wear and ensure stable processes. Using these coolant holes, nozzles direct coolant to the clamping flat from above as well as from below to the flank. This additional flank cooling contributes to the tools ability to extend tool life by 60% compared those that cool only at the clamping flat.

To avoid interference with workpiece contours, the lengths of DirectCooling Series holders are ideally matched to one another and offer optimal stability and unlimited flexibility. This flexibility is further enhanced with an HSK-T universal standard interface for turning tools that ensures straightforward connection to multifunction machines such as turning/milling centers and milling/turning centers.

For more information or to download the interactive, February 2023 UP2DATE catalog click here.

www.cuttingtools.ceratizit.com

About CERATIZIT USA, Inc.

Part of the CERATIZIT Group, CERATIZIT USA designs and manufactures high quality standard and custom tooling for the metalworking industry. With headquarters in Schaumburg, Illinois, CERATIZIT USA is a solutions and service provider for many different industry segments, including automotive, aerospace, and energy. With a highly specialized staff, expansive product portfolio and an International Traffic in Arms Regulations (ITAR) registration, CERATIZIT USA provides manufacturers with the complete application engineering, service and training support needed for maximum productivity and cost-effectiveness.

Subscribe to learn the latest in manufacturing.