Dependable and Affordable Welders and Welding Technologies Get the Job Done

Multiple options, robotic cell premiers, automated systems, and enhanced and upgraded technologies result in easy to program and use equipment, keeping workers and management happy.

Posted: March 16, 2023

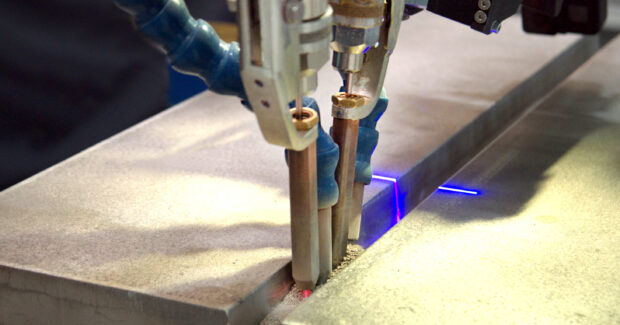

First-of-its-Kind Robotic Cell Automated TIG Welding Solution

Automation is the word in manufacturing today, and CINCINNATI Inc. (Harrison, OH) is continuing its tradition of innovation with the introduction of the industry’s newest welding technology. Simple to use and easy to program, the CINCINNATI Cobotic 100T Welding Cell is the first of its kind for TIG welding.

With a working range of 2400 mm-x-1200 mm (approx. 4’-x-8’) the automated system is suitable for large or small production batches. The cell is compact, easily repositioned, and contains advanced safety devices including the continuous robot elbow monitoring.

CINCINNATI’s Ryan Lemmel, the aftersales business unit leader, explained that the system offers advanced automation and features that make the system powerful yet easy to operate while measurably impacting the bottom line.

“With a touchscreen control interface and intuitive programming buttons, processes are quick and simple,” Lemmel said. “We’ve eliminated complicated off-line programming allowing the robot to be programmed using a tablet and buttons on the torch. The 100T autonomously detects sheet metal deformation without operator intervention. Automating the welding process maximizes limited resources and advances productivity by allowing shop floor personnel to be allocated away from welding operations.”

MIG and Multi-process Inverters are Loaded with Features in a Portable, Affordable Package

ESAB (North Bethesda, MD), a world leader in fabrication technology, offers a new series of Rogue EM (ESAB MIG) and Rogue EMP (ESAB Multi-process) inverter-based welding power sources. These easy-to-use, compact and lightweight welders feature an industrial design with digital controls and a five-handle roll cage for portability, cable management and protection. They appeal to users in various industries, including light fabrication and light construction industries.

The Rogue EM 125i, Rogue EM 140i, Rogue EM 180i, Rogue EM 190i, Rogue EM 210i MIG/flux cored welders and Rogue EMP 210i multi-process welder will be available globally in 2023. They use state-of-the-art power management technology to create positive arc starts and a smooth, stable welding arc with minimal spatter. All Rogue EM and EMP welders feature Arc Dynamics, a control to fine-tune arc characteristics for a crisp/stiff arc when welding carbon steel or a smooth/soft arc when welding stainless steel.

The Rogue EM 125i (maximum output of 125A) and Rogue EM 140i (maximum output of 140A) each weigh 28 lbs. and use 115V primary power. They both have a rated welding output of 90A at 30% duty and are optimized for use with .023” and .030” diameter solid MIG wires or .030” gasless flux cored wires. The Rogue EM 180i connects to 230V primary power to provide a maximum welding output of 180A to weld thicker materials and use .035” solid and cored wires. All three machines accept 4” and 8” diameter spools of wire. A 14-segment digital display shows parameters and details, and users set voltage and wire feed speed (which controls amperage) with traditional controls.

The Rogue EM 190i connects to 230V primary power, offers a maximum output of 190A, weighs 29 lbs. and features a 5” TFT LCD display, largest in its class. Using the display and adjustment knobs, operators can set advanced functions found in industrial systems, such as wire run-in speed (for softer arc starts), burnback control (to ensure the wire does not stick in the weld puddle), 2T/4T trigger control (standard or “latch” mode to reduce hand fatigue) and gas pre-flow and post-flow (to prevent weld puddle contamination). A Spool Gun Detection feature automatically detects when a spool gun is connected.

Rogue EM 190i also provides Synergic Control, which enables one-knob adjustment where welders set the wire type, wire diameter and shielding gas mix. Rogue will then automatically set and maintain optimized welding parameters throughout the range of material thicknesses. The Rogue EM 190i also features Power Factor Correction, which increases electrical efficiency, reducing the likelihood of tripping a circuit breaker.

For even more performance and location flexibility, welders can step up to the Rogue EM 210i and Rogue EMP 210i. They provide maximum output of 210A, weigh 29 lbs., connect to 115V/230V primary power and feature PFC and Synergic Control. The 5” TFT LCD display enables users to access a full suite of advanced MIG (Rogue EM 210i) and MIG/Stick/TIG (Rogue EMP 210i) process controls to further improve welding performance.

Solid, Dependable 200-amp MIG Welder

Lincoln Electric (Cleveland, OH) offers the POWER MIG® 211i MIG welder, the newest member of the Power MIG family of welding machines. This welder is a straightforward, dependable 200-amp machine — for MIG, flux-cored, and spool gun welding — that you can depend on for just about any environment or application: the small shop, maintenance, repair work and more.

The POWER MIG 211i is portable enough to find its way into all of these places, thanks to the sleek design with multiple lift points and inverter technology that reduces weight while maximizing power, ensuring more efficient operation. At 41 lbs., this machine can go anywhere and handle any job.

The user interface is incredibly simple. The seven-segment display and basic knob controls enable you to get to welding quickly in a simple three-step process: 1) select welding process, 2) select wire diameter, and 3) select material thickness. The machine takes it from there, automatically providing the optimal voltage and wire feed speed settings.

“The lightweight, portable design combined with the incredibly easy to use interface enable the operator to start welding in seconds,” said Joe Keipert, commercial products manager at Lincoln Electric.

The POWER MIG 211i has a duty cycle of 175 @30% and can operate on 120V or 230V input voltage, enabling you to power up wherever and whenever you need to. The machine is loaded with accessories and attractively priced.

New Collaborative Welding System is the Most Intuitive Welding Cobot

Miller Electric Mfg. LLC (Appleton, WI), a leading worldwide manufacturer of Miller® brand arc welding equipment, offers the Copilot™ Collaborative Welding System. This all-Miller system is an entry-level cobot with advanced capabilities designed for shops and welders who are new to robotic welding and looking for ways to keep up with demand.

The welder-centric design removes complexity and makes it easy to handle quick changeovers for high-mix, low-volume parts. With effortless implementation and ease of use, welders of any skill level will be empowered to take on more, expand their skill sets and optimize their time — all while the Copilot system continually produces repeatable, high-quality welds.

“Our goal was to create a system that’s focused on automated welding for users who have never programmed robots before — to take their different skill levels and amplify them,” said David Savage, product manager, Miller Welding Automation. “I think we’ve nailed it.”

Built to be rugged and reliable, the Copilot system is the only cobot with Miller-developed software, fine-tuning capabilities, and the ability to easily set and store parameters. Powered by the Auto-Continuum™ 350 welding power source and featuring Accu-Pulse®, Versa-Pulse™ and Regulated Metal Deposition® welding processes, the Copilot system will grow with businesses and operations as they take on more projects.

Exclusive Copilot features include:

- AccuGuide™ Precision Joystick

For the most accurate welds, the AccuGuide Precision Joystick simplifies precise gun positioning and adjustment with easy, fingertip control.

- IntelliSet™ Weld Settings Assistant

Welders simply input the material thickness and wire diameter and IntelliSet technology will configure the ideal settings for the best results.

“A common reaction to automation offerings is concern that ‘robots will take my job.’ We’re finding that with the Copilot system, it’s just the opposite,” said Ross Fleischmann, marketing manager, Miller Welding Automation. “Welders quickly identify that it’s another tool to help them, like their MIG gun. With the Copilot system, the skilled welding workforce is going to increase their value and extend their capabilities.”

Cutting and Grinding Wheels for Aluminum are Best in Class

Saint-Gobain Abrasives (Worcester, MA), one of the world’s largest abrasives manufacturers, offers Norton for Aluminum Thin Wheels for the right angle cutting and grinding of aluminum and other non-ferrous soft metals. High quality, extra-friable and self-sharpening aluminum oxide grain and specialized bond technology results in the best cutting and grinding wheel market performance in its class. These wheels offer aggressive, fast cutting that resist loading and minimizes heat on the workpiece, providing consistent, long-lasting wheel performance.

The wheels have a range of features and benefits including a 5/8″-to-11″ hub for quick, tool-free wheel changes. Helping to keep metal surfaces clean for defect-free, corrosion-free welding, the new wheels have a contaminate-free bond that does not need waxes or lubricants. Also, a double coarse layer construction adds versatility and life on applications such as back-grinding and notching.

Norton for Aluminum Thin Wheels construction is strong and safe, exceeding the North American ANSI and international safety standards. Applications include aluminum, cut-off, portable grinding, beveling, notching, smoothing welds and offhand stock removal. The wheels are available in 1/4″ Grinding Type 27, 1/8″ Cutting/ Notching/ Grinding Type 27, .045″ Right Angle Cut-Off Types 01/41 and 27/42, and Straight Cut-Off Type 01/41.

Solutions for Semi-Narrow Groove Welding Technologies for Thick Plates

Pemamek LLC (Mason, OH), a North American subsidiary of Finland-based Pemamek Ltd., has developed an automated semi-narrow groove welding solution with proven success in welding exceptionally thick plates ranging in size from 2-to-6.5”. Called Semi-Narrow Gap Welding, this Submerged Arc Welding (SAW) process uses significantly less consumables over the length of the operation resulting in a strong bond in less time and with fewer costs.

Based on SAW, the LSO process employs a welding head equipped with 5/32” wires. Stick-out is defined as the distance between the contact tip to the wire end. Pemamek’s tiltable welding head provides more control over the fusion process and welds bead creation for better accuracy and penetration. Full welds are possible from the root weld all the way through to the surface. For welding tubular structures, longitudinal and circular milling machines are used to mill the groove root; a 16-degree included angle is standard with an 8-degree radius on the base. The tiltable welding head helps direct the energy into the side walls of the semi-narrow groove for full penetration. Any unconsumed flux can be vacuumed, circulated and recycled.

“Pemamek’s specialized milling machines can mill both longitudinal and circular grooves,” said Michael Bell, director of sales for Pemamek North America. “They mill the semi-narrow gap bevel immediately after the inside seam of the weld piece is welded hereby milling out the root to achieve a perfect fusion. By starting with a workpiece milled to the ideal welding groove geometry, the volume of the weld joint is minimized while the joint itself is geometrically correct with clean groove edges, which is especially important when working with the external side of a tubular structure. Additionally, deformations and tensions are kept to a minimum because inefficient and imprecise back gouging is no longer required.”

New and Upgraded High-Precision Automated Plasma Sources

Thermal Dynamics® Automation’s (West Lebanon, NH) new UC Series of high-precision automated plasma sources, an updated version of its Ultra-Cut® XT systems, features a modernized inverter block with state-of-the-art power switching components, a new cabinet design with an LED strip for an at-a-glance assessment of machine status. The UC Series features four models, all rated at 100% duty cycle: the UC 131 (130A), UC 201 (200A), UC 301 (300A) and UC 401 (400A).

“Over the last two years, we made so many incremental improvements to cut faster, better and smarter that it warranted rebranding our high-precision automated plasma systems as the UC Series,” said Dirk Ott, vice president of global plasma automation, Thermal Dynamics. “For example, two UC 201, UC 301 or UC 401 can now be connected doubling cutting output to 400, 600 or 800 amps, respectively, or they can operate independently.”

Target applications for this new capability, which is similar to paralleling welders, include fabricators and steel services centers that use two torches on the same gantry and want to increase cutting speeds on steel plates up to 2” (50 mm) thick. It also lets fabricators cut stainless steel and aluminum sections up to 6.25” (160 mm) for applications in the power generation, pressure vessel, chemical and petrochemical processing industries. To double a torch’s cutting output, users need to change the SpeedLok™ consumables cartridge, which takes less than a minute.

“This new capability features modest software and hardware enhancements, but the challenge was developing the new 600A and 800A consumables for stainless steel and aluminum that fit into the same footprint as our existing SpeedLok consumables,” Ott said.

The UC 131 features new consumables and is optimized for piercing and cutting 3/4″ (20 mm) steel, stainless and aluminum. It covers the majority of high-precision cutting applications at an aggressive price point, and it offers a good retrofit opportunity for older 100A systems. Compared to the previous Ultra-Cut 100 XT, it offers 30% more power, 20% faster cutting speed and 50% longer parts life when cutting at 130A on mild steel. The UC 131 cuts 3/4″ steel at 52 IPM (20 mm at 1321 mm/min) and 1/2″ steel at 85 IPM (12 mm at 2159 mm/min).

Other improvements Thermal Dynamics made to its UC high-precision systems to boost performance and quality include new bevel wear parts, bevel angle data, improved XT torch head and more.

Enhanced Technology for Unicables Increases Cable Life up to 300%

Tregaskiss (Windsor, Ontario, Canada) has enhanced its LSR+ (Low Stress Robotic) unicables with SmoothTurn™ technology for use with TOUGH GUN® TA3 robotic MIG guns. This technology reduces friction on the internal components in the power cable, increasing overall cable life up to 300% and maximizing productivity.

While conventional unicables generally have connections with limited rotational capability, producing torsional stress, the LSR+ unicable has a rotating power connection to reduce that stress. Tregaskiss also incorporated improved electrical connections to ensure a more stable arc, resulting in reduced spatter.

Special internal components increase power cable support and bend radius to better accommodate heavy robot articulation. The addition of a protective external conduit further extends cable life by guarding components against harsh elements in the robotic welding cell.

The LSR+ unicables complement the other durable features of the TOUGH GUN TA3 robotic guns, including the aluminum armored neck, the precision-engineered keyway system for accurate alignment and a resilient neck clamp.

New Welding Helmet Offers a Wider Fit with Innovative Features

WALTER Surface Technologies’ (Windsor, CT) new ORBIT™ welding helmet offers innovative features like three high-definition auto-darkening lenses with a three-year warranty, anti-scratch cover plates, and a 24-square-inch viewing area. The three lenses and viewing area offer optimal peripheral vision for increased safety and productivity while on the job. In addition, its HD technology allows you to see colors well and have a clearer and more defined view to ensure your senses are not impaired when wearing the helmet, furthering WALTER’s commitment to safety and productivity.

It also includes external controls for shade adjustment and for selecting grind mode without having to lift the hood. It is solar powered and has a USB charger for backup charging for enhanced ease of use.

Subscribe to learn the latest in manufacturing.