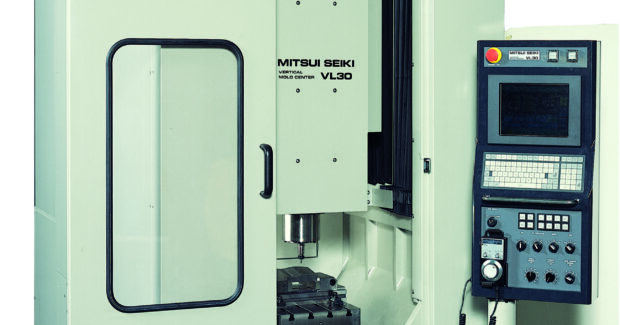

Mitsui Seiki Introduces Upgraded High-speed Vertical Precision Center

The VL30 Series features high thrust, high-efficiency linear motor drives for the X, Y and Z axes for machining hardened tool steel alloy components.

Posted: March 16, 2023

The Mitsui Seiki VL30 Series high-speed vertical machining centers were developed specifically for high-speed/high-precision hard milling of mold components as well as graphite and copper tungsten electrodes. The VL30 Series features high thrust, high-efficiency linear motor drives for the X, Y and Z axes for machining hardened tool steel alloy components. The 5-axis versions use Direct Drive rotary axes for smooth and perfectly controlled complex contouring. Delivering up to 1,574 ipm cutting feed rate with 1G acceleration/deceleration, it provides superior speed and motion control in performing high-speed point milling in multi-axis contouring applications. For accuracy, the precision glass scale feedback system detects 0.1micron increments.

The VL30 line has a proven track record of machining high-precision mold inserts for a wide variety of applications for medical, packaging, industrial, and aerospace applications for demanding manufacturers.

The upgraded offerings include advanced features for process automation, work piece and tool handling, and the latest Fanuc 31i-B with i-HMI operator interface making it easier than ever before to realize improved output and profitability. The latest Graphite Package option allows customers to machine completely dry with no risk of electrode contamination or premature machine wear. All versions allow simple integration with robotics and in-process part inspection.

Available in three models, the VL 30-5X five-axis machining center, and VL 30, and larger VL 50 3-axis versions, this series features a 15 hp 50,000 rpm spindle accepting HSK E25 tooling for precise roughing and ultra-fine finishing. An integrated tool changer holds up to 90 tools.

Specifications include 7.9 in. x 11.8 in. x 7.9 in. X, Y, Z axis travels, 11.8 in. x 15.8 in. table size and a compact 53 in. x 128 in. footprint.

Enhanced production features include a 4-point leveling bed, F.E.A. (finite element analysis)-designed main components, hand-scraped castings for excellent machine geometry and superior chip and dust evacuation with a choice of solution to suit most needs.

Subscribe to learn the latest in manufacturing.