New Vertical Market Dedicated to Intralogistics in the U.S.

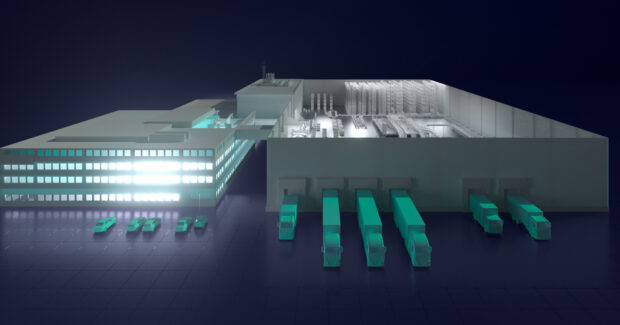

The Siemens Intralogistics segment will provide a holistic, systematic approach for materials handling, addressing the needs for digital transformation, cybersecurity, safety and sustainability.

Posted: March 15, 2023

Siemens recently announced the formation of the new Intralogistics vertical that brings best-in-class material handling thought leadership, hardware automation, software and service solutions to customers in the United States. Siemens is leveraging its broad technology to address the market needs for digital transformation, cybersecurity, safety and sustainability. This new group will operate both as a vertical industry group and a horizontal business operation. It will reside within the Siemens Digital Industries — Motion Control business and functions in tandem with the organization’s existing additive manufacturing, aerospace, automotive, food-and-beverage, and other industry verticals.

Joel Thomas is the head of the Intralogistics vertical. Besides management of the group, Thomas will also work closely with trade associations who serve the intralogistics industry and will foster programs at Siemens to educate the next generation of engineers, programmers, software developers and plant operations personnel who will manage the warehouses of the future.

This new group will serve machine builders and end-customers alike. For example, using the Siemens TIA Portal, a warehouse facility or postal clearing house will be able to integrate all its motion control hardware, software systems and communications protocols, internal and external, as needed. Additionally, Siemens digital twin and simulation technologies allow a warehouse or manufacturing operation to test all the “what ifs” before taking action on a material handling challenge.

Further, notes Joel Thomas, “The goal for all companies should be smart manufacturing and automated material flow, which is adaptable to changing market and technology conditions. This is especially challenging in older brownfield operations, where the legacy equipment might not handle the needs of the company, tomorrow or even today.”

Predictive analytics and predictive maintenance will also be among the key drivers for the Siemens Intralogistics business, as it strives to offer users the needed system components to maximize productivity and to gather the data needed to monitor and maintain the operation. The biggest challenge for this new group, according to Thomas, is to identify and bring the necessary skills and solutions to the resident knowledge base for each customer. He notes this varies considerably based upon each company’s size and onboard skill sets.

Thomas also comments how sustainability, which involves energy consumption and the ability to anticipate what equipment and software will be needed in the future to keep the plant running at maximum efficiency, will be a critical factor in the service package provided to customers.

Lastly, with use of this digital-to-real world technology, the Intralogistics business will help companies achieve a more productive eco-system and, with various Siemens solutions and services, a homogenous environment in the future-proofing of their operations.

Subscribe to learn the latest in manufacturing.