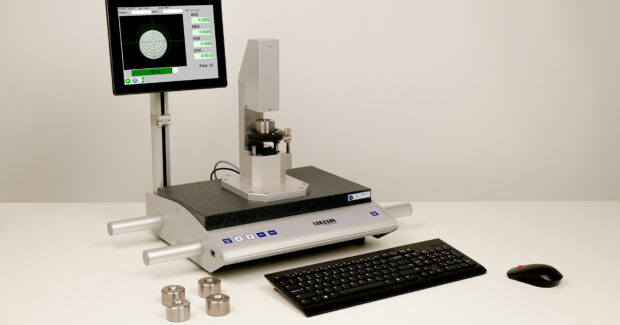

New Aeroel D-Lab Available for Contactless Measurement of Drawing Dies

Marposs Corp.’s Aeroel D-Lab is able to capture a measurement within 1 second and with +.01 µm repeatability.

Posted: April 27, 2023

Marposs has announced its Aeroel D-Lab, a table-top non-contact measuring system for controlling the diameter (avg, max, min) and ovality of drawing dies for wire and other extruded products. D-Lab is able to capture the measurement within 1 second and with +.01 µm repeatability. It works by comparing the diameter and ovality against a pre-set nominal value and a tolerance range, immediately displaying colors indicating the tolerance status of the part. These systems are ultra-accurate, highly flexible, extremely fast and easy to use regardless of operator skill level.

The D-Lab can be used to measure different dies without requiring system re-mastering. It also features intuitive software along with an extensive number of control sets (tolerance limits, measuring mode, etc.) stored in a “part library”, making it very easy to use. Additionally, its rugged construction is designed to withstand workshop environments.

The D-Lab has a measuring range of 0.5mm – 8mm, repeatability of ± 0.01 µm, resolution of 0.1 µm and accuracy between +1.0 – +2.0 µm, depending upon the die size. All measured data is saved in the computer memory and ready to be exported in test or CVS format. A statistical report is available, which can be immediately printed by using a standard PC printer.

The D-Lab non-contact technology is based on telecentric optics with an LED collimated illuminator. The image is analyzed using a 2D CMOS sensor and subpixel edge detecting algorithm.

https://www.aeroel.it/eng/product/d-lab

Subscribe to learn the latest in manufacturing.