New Infrared Conveyor Ovens up to 78-inches Wide

Vastex Industrial EconoRed Series VI conveyor ovens are equipped with six infrared heaters in a single chamber for rapid curing, drying or preheating of parts, laminates and coatings.

Posted: April 14, 2023

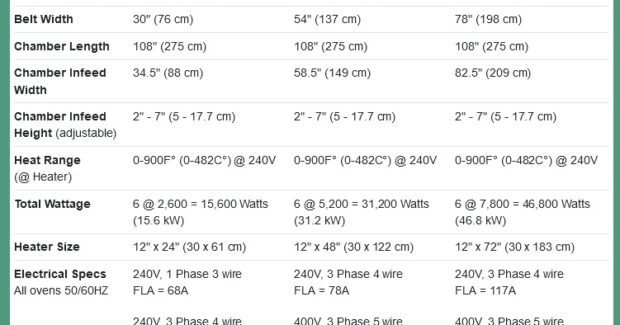

New EconoRed™ Series VI conveyor ovens, available in 30, 54 and 78 in. (76, 137 and 198 cm) widths, are equipped with six infrared heaters in a single chamber for rapid curing, drying or preheating of parts, laminates and coatings.

Model ER-VI-30 offers a 30 in. (76 cm) wide conveyor belt and 15,600 watts of power―model ER-VI-54, a 54 in. (137 cm) belt and 31,200 watts. Model ER-VI-78 with 46,800 watts and a 78 in. (198 cm) wide belt can accommodate large parts, sheet and film products in single or multiple rows.

All models include a digital PID temperature controller accurate to +/- 1°F (+/-0.5°C), and an exhaust system that removes fumes and moisture while cooling the chamber’s outer skin for operator safety.

The 13.25 ft (404 cm) long conveyor belt runs true by means of a low friction belt aligner patented by the company, with digital belt speed controls allowing infinitely adjustable dwell times to suit process requirements.

Capacity (belt speed) can be doubled or tripled as new or when needs increase by adding one or two modular heating chambers and extending the conveyor belt, increasing throughput in direct proportion to each additional chamber.

Heaters come with a 15-year warranty and are height adjustable from 2 to 7 in. (5 to 17.7 cm) to accommodate parts as well as sheet products.

A Teflon®-coated fiberglass belt is standard, with optional Kevlar® and stainless steel mesh belts available for high-heat and/or sanitary applications.

Other options include: Conveyor Extensions at the infeed or discharge end of the oven to optimize loading and cooling/unloading of products; a Conveyor Air Bar to speed the cooling and handling of items exiting the chamber; and an Exhaust Hood that can be mounted to the rear of the unit to remove fumes of adhesives, inks and other coatings that continue to off-gas after exiting the chamber.

Also offered are conveyor models with infrared heaters up to 68,400 Watts, and cabinet/batch ovens with forced, filtered air, adjustable racks and stainless steel finned strip heaters up to 3,100 Watts.

Subscribe to learn the latest in manufacturing.