Optimize Your Facility’s Airflow by Safely Capturing Fumes and Dust

Determine how best to clear the air, extend the life of your products, and conduct effective maintenance of equipment.

Posted: April 19, 2023

Keep your employees and facility safe from the toxic fumes and combustible dust associated with metalworking with the latest in extraction and air filtration systems.

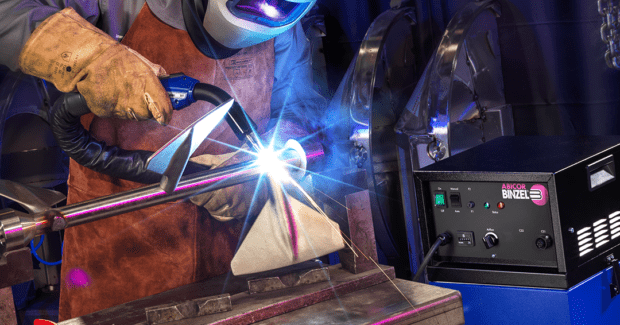

Lightweight Fume Extraction

ABICOR BINZEL (Frederick, MD) continues to strive to develop and provide the best fume extraction solutions on the market. The most recent product release is the xFUME® PRO, which includes improvements made to the front-end design and decrease the weight of internal components by 20%.

To fully realize the performance benefits of the xFUME PRO, we recommend pairing it with our xFUME ADVANCED fume extraction vacuum systems.

Through coordination between a high-vacuum system and a high-vacuum welding gun, we ensure highly efficient extraction directly at the source with a clear view of the arc. Our complete xFUME fume extraction product line easily integrates into your current welding operation. When the high-vacuum system and high-vacuum welding gun are used in tandem, this creates an optimal welding environment to keep your welders safe from toxic fumes.

As with all our MIG guns, the xFUME extraction MIG guns can be connected to any wire feeder/machine on the market by utilizing our various connector kits and adapters.

The overall goal of ABICOR BINZEL is to improve the working conditions of the welder and providing solutions in the process. Not only by protecting them from toxic welding fumes, but also by reducing the physical impact of welding day-in and day-out.

General Ventilation Self-cleaning Dust Collector — Key Intelligence Behind the IVEC Ultra System

Hastings Air Energy Control, Inc. (New Berlin, WI) offers medium to heavy duty ambient systems. 5,000-to-20,000 CFM with IVEC controls maintain optimum airflow and manage the automated self-cleaning system to improve air filtration, extend filter life and reduce equipment maintenance requirements. Used in medium to heavy-duty ambient air cleaning systems for fine to heavier metal and composite dust and solids found in welding, grinding and finishing as well as plasma, laser, and arc cutting.

Advantaged Operating Characteristics:

- Extremely Low Air-to-Cloth Ratio

- Dual Action, Self-Cleaning Filter System

- Very Quiet

- Easy to Maintain

Cost Reduction Guarantee:

- Low Up-Front Cost per CFM

- Lower Energy Costs by up to 85%

- Significantly Improved Filter Life

- Lower Maintenance Costs

https://hastingsair.com/products/ivec-ultra-dust-collection-system/

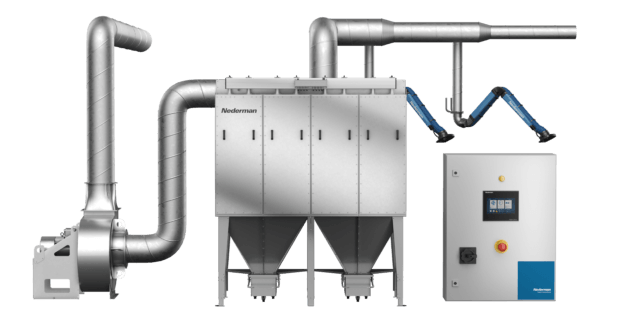

Complete Industrial Air Filtration Solution

Nederman – The Clean Air Co. (Charlotte, NC), a global leader in industrial air filtration technology, introduces the new MCP SmartFilter. The MCP SmartFilter is ideal for safely handling fumes and combustible dust associated with multi-source metal fabrication processes. MCP brings together industry-leading filtration technology in a smarter way that leads to improved air quality, reduced operating costs, improved processes and worker safety. But more importantly, it enables you to focus more time on your business by relying on Nederman to support your factory’s clean air needs.

Optimized, Flexible Design

- Innovative squircle-shaped cartridge design optimizes space within the dust collector, generating high airflow and enables easier filter maintenance.

- Horizontally stacked nanofiber filter medias improve ability to handle fume applications more effectively with high dust holding capacity and improved filter cleaning.

- Enhanced IntelliPULSE™ cleaning mode and UniClean filter cleaning that reduces compressed air and energy consumption, decreases emissions from fewer required pulse cleaning cycles, improves management of filter pressure drop and reduces overall operational costs.

- Flexible, modular design configured to match your specific needs with a wide range of options and accessories.

Future-proof IIoT Filtration Solution and Service

- Smart components and controls capable of monitoring the system performance through Nederman Insight: a cloud-based, filtration specific IIoT solution.

- Real-time data accessible via the web or mobile devices featuring auto-generated alerts and notifications.

- Operate and maintain your filtration system more effectively improving plant productivity, worker safety, regulatory compliance and energy consumption.

Solutions to Help Workers Breathe Safely

WALTER Surface Technologies (Windsor, CT) has been helping metalworkers achieve greatness for more than 70 years and now offers a wide array of trusted ventilation solutions, like it’s newly acquired Allegro blowers. Made from premium materials, these fully certified blowers adhere to OSHA standard 1910.146 and are the safest and most reliable ventilation solution for any type of work environment or application. They are particularly useful when working in confined spaces, where ventilation options are limited, to not only properly ventilate the area but also remove potentially poisonous, explosive, or hazardous fumes.

For robust, industrial applications, Venturi blowers are a great option. Built from lightweight one-piece construction without any moving parts, they are extremely portable, maintenance-free, and can be used in hazardous locations. They are often used in refineries, utility and power plants, shipyards, paper and pulp plants, marine and steel industries, and manhole operations due to their high yield and versatility.

The Allegro plastic axial blower options are compact and lightweight, allowing for easy portability to and from the job site. They are made from UV-, corrosion-, and chemical-resistant polyethylene and are durable enough to withstand any rugged condition. Rust-proof metal blower options are available where higher amounts of CFM are needed and are also designed to be extremely durable and reliable.

In some environments, ventilation is simply not enough. That is why WALTER offers an extensive line of respiratory solutions, from air purifying respirators to supplied air systems, depending on the hazards employees may be exposed to. For questions on respiratory safety, our safety specialists would be happy to help and for information on which blower is the best for each application, users may explore Blower Selector tool on the Allegro website.

Subscribe to learn the latest in manufacturing.