Latest Version of Robotic Offline Programming Software Addresses Market Trends

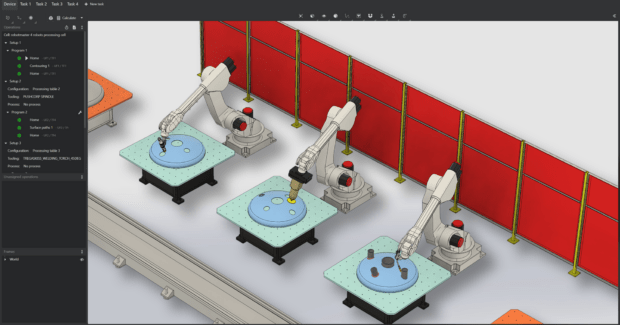

Among its updates, Robotmaster 2024 supports programming multiple robots in a work cell, and meets the demand for automatic trajectory optimization and robotic error correction.

Posted: May 11, 2023

Hypertherm Associates, a U.S.-based manufacturer of industrial cutting products and software, recently announced the latest version of its offline programming software with the launch of Robotmaster® 2024.

Addressing key market trends, Robotmaster 2024 supports programming multiple robots in a single work cell and meets the demand for automatic trajectory optimization and robotic error correction. In addition, the software update includes improvements to the cell and tooling editor, as well as improvements to the UX (User Experience) and UI (User Interface) to ease the programming experience, maximizing productivity for the user.

“We are excited to announce the release of Robotmaster 2024,” said Natalie Adams, Hypertherm Associates product marketing manager for Robotmaster robotic software. “This latest version of our robotic programming software includes new features and functionality that not only decreases programming time but also removes many of the programming nuisance’s robot programmers encounter.”

Robotmaster 2024 is designed for users who need to program multiple robots to perform a variety of processes within the same cell environment. The ability to program multiple robots enhances the programming workflow and gives the user a single view of the entire system to review the workspace for collisions. In addition, users can now leverage Robotmaster’s powerful programming capabilities and unmatched optimization strategies to shorten cycle times and increase output in multi-robot cell environments.

Robotmaster 2024 also comes equipped with Auto Solve, a new automatic optimization and error correction tool. Auto Solve empowers users of all levels of expertise to program industrial robots confidently in alignment with Hypertherm Associates’ mission to deliver an intuitive and easy-to-use software solution.

“Auto Solve leverages our users’ favorite optimization and correction tools. We’ve designed this new feature so that users can optimize the robot trajectory and correct robotic errors in a single click,” said Daniel Marcovici, Hypertherm Associates senior product owner for Robotmaster robotic software.

Robotmaster, a Hypertherm Associates brand, is an offline programming software for robots that helps manufacturers maximize productivity on production runs of all sizes. Robotmaster makes programming parts of any complexity quick and easy as a result of its integrated CAD/CAM functionality. This intuitive and powerful solution is designed with process experts in mind reducing the need for programming and robotic expertise. Learn more at www.robotmaster.com.

Subscribe to learn the latest in manufacturing.