Machine Innovations Drive Opportunities

Seamlessly integrate automation solutions with multitasking and EDM machines to achieve unparalleled throughput.

Posted: June 16, 2023

METAL CUTTING

The next generation of multitasking machines, which combine one or two lathes with a machining center, and electric discharge machines (EDMs), continue to elevate metal cutting performance for a variety of materials. Thanks to advances in control units and automation that assists in unmanned operations, quality, cost savings and the ability to overcome labor challenges are realized.

High-precision Multitasking Milling Machine Improves Productivity

The OPS Ingersoll Eagle V9C 5-axis milling machine from MC Machinery (Elk Grove Village, IL) is equipped with an integrated direct drive high-dynamic 4th/5th axis rotary table, which can handle a 550-lb. workpiece on a 23.6” table surface.

Other key features include:

● Stable gantry/bridge-style design

● Vibration-damping polymer concrete machine base

● Large work envelope

● Advanced thermal compensation on all axes

● High-precision ball screws

● Automation ready: It is designed with a side opening in the casting to allow robot loading from the right side with pallets up to 19.7” square.

● User-friendly controls: The HEIDENHAIN TNC 640 control unit is mounted on a movable pedestal for optimal positioning convenience.

● Serviced by MC Machinery’s robust service network

Other benefits include consolidation of operations with multiple axes and tool changers; simultaneous 5-axis machining; improved accuracy with the HEIDENHAIN TNC640 5-axis CNC control; reduced setup time with the workpiece secured in a single setup; increased flexibility to adapt to changing production requirements; and cost savings with fewer workers, minimizing material waste and lowering energy consumption.

New Series of Wire EDMs

GF Machining Solutions (Lincolnshire, IL) recently launched the first model of its new CUT F Series of wire electrical discharge machines (EDMs). The new CUT F 600 is designed for ease of use and flexibility thanks to many of the company’s most innovative technologies. These include the Uniqua control, ISPS and iWire intelligent functions along with design enhancements for thermal stabilization, vibration control and machine movement precision.

The CUT F 600’s intuitive Uniqua human-machine interface delivers optimal functionality and ergonomics with a 19″ vertical touchscreen, full keyboard and mouse. Uniqua supports legacy file types from various EDM manufacturers, and with offline and at-the-machine programming, ISO-based functionality and object-oriented programming, Uniqua provides a powerful graphic tool with integrated CAM and ensures compatibility with major CAD/CAM programs.

The iWire function, a true innovation for the industry, of the CUT F 600 automatically identifies and adapts wire speed to changing erosion height conditions during the wire EDM process. This capability eliminates wire breakage while reducing overall wire consumption per job, in some instances by as much as 29%. The iWire function works in tandem with the company’s Intelligent Spark Protection System (ISPS), both of which are part of the Uniqua control.

iWire can not only recognize exactly where the sparks of a wire EDM are happening during the process, it can also measure and identify the position of each spark along the length of an EDM’s wire. Knowing the exact location of a spark allows iWire to automatically adapt the wire spool speed accordingly. Such capability reduces the chances of wire breakage during unattended operations when EDMing parts with steps and other features that vary the erosion height – the length of the actual surface areas where the wire is eroding/cutting.

5-Axis Machining Center Offers Optimal Milling Performance

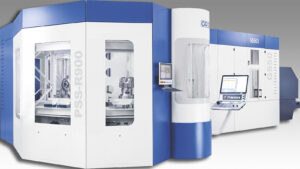

GROB Systems, Inc. (Bluffton, OH) demonstrated its G550 Generation 2 5-Axis Machining Center integrated with the PSS-R900 rotary pallet storage system at EASTEC earlier this year. GROB machining centers are made in the USA at GROB Systems’ 400,000-square-foot production facility in Ohio and include advanced automation solutions for dramatically increased productivity.

The G550 Generation 2 offers optimized milling performance for a broad range of part materials, and is equipped with a Siemens 840D SL control, 16k rpm spindle, and an HSK-A63 tool interface. The G550’s unique machine concept includes a horizontal spindle position that permits the longest possible Z-travel path and optimum chip fall. The arrangement of three linear axes offers maximum stability by minimizing the distance between the guides and the machining point (TCP).

The G550’s tunnel concept allows the largest possible component to be swiveled and machined within the work area without collision — even with extremely long tools. Three linear and two rotary axes permit 5-sided machining, as well as 5-axis simultaneous interpolation, with a swivel range of 230° in the A-axis and 360° in the B-axis.

The PSS-R900 rotary pallet storage system is a modular system with up to 13 pallets that can significantly increase machine utilization and productivity with longer unmanned periods. It has a high storage capacity and offers an easily accessible setup station next to the machine control panel, which can be rotated and locked.

Quality and Reliability Within Reach of Virtually any Shop

The Mazak Corp.’s (Florence, KY) QT-Ez 12MY Multi-Tasking Turner Center features milling and Y-axis off-centerline capability. For further increased productivity and unmanned operations, the machine seamlessly integrates with a range of automation solutions. These include simple bar feeders and parts catchers as well as full cooperative robot installations such as Mazak Automation Systems’ Cobot Cell System.

While the machine comes standard with a 12” chuck, Mazak offers a smaller 10” option. Available bed lengths are 20” and 40”, and machine turrets include 2-axis drum style with a bolt-on or BMT55 turret for rotary tool applications. Tailstocks are offered with either manual positioning via hydraulic quill or servo positioning capability.

All QT-Ez models feature powerful and reliable integral motor headstocks, Hybrid MX roller guideways and pre-tensioned ball screws supported at both ends for reliable, thermally stable, and precise machine axis movement. An innovative bed casting design provides outstanding rigidity as well as streamlined chip flow that helps to eliminate chip accumulation.

Mazak equips all its Ez Series machines with its MAZATROL SmoothEz CNC that provides dual 800 MHz processors, 512 MB of RAM and a vibrant 15″ capacitive touch screen that includes a full keyboard and displays up to 60 lines of code.

Upgraded High Speed Vertical Precision Center

Mitsui Seiki USA, Inc.’s (Franklin Lakes, NJ) VL30 Series high-speed vertical machining centers were developed specifically for high-speed/high-precision hard milling of mold components as well as graphite and copper tungsten electrodes. The VL30 Series features high thrust, high-efficiency linear motor drives for the X, Y and Z axes for machining hardened tool steel alloy components. The 5-axis versions utilize direct drive rotary axes for smooth and perfectly controlled complex contouring. Delivering up to 1,574 ipm cutting feed rate with 1G acceleration/deceleration, it provides superior speed and motion control in performing high-speed point milling in multi-axis contouring applications. For accuracy, the precision glass scale feedback system detects 0.1micron increments.

The VL30 line has a proven track record of machining high-precision mold inserts for a wide variety of applications for medical, packaging, industrial, and aerospace applications. The upgraded offerings include advanced features for process automation, workpiece and tool handling, and the latest FANUC 31i-B with i-HMI operator interface making it easier than ever before to realize improved output and profitability. The latest Graphite Package option allows customers to machine completely dry with no risk of electrode contamination or premature machine wear. All versions allow simple integration with robotics and in-process part inspection.

Available in three models, the VL30 Series features a 15 hp 50,000 rpm spindle accepting HSK E25 tooling for precise roughing and ultra-fine finishing. An integrated tool changer holds up to 90 tools.

Subscribe to learn the latest in manufacturing.