Sneak Preview: FABTECH 2023

Foremost metal fabrication event returns to Chicago with live product demonstrations, a comprehensive conference portion, unique events and much more.

Posted: June 15, 2023

FABTECH 2023, “Driving Manufacturing Forward” will take place at Chicago’s McCormick Place, September 11-14. There will be more than 1,300 suppliers displaying and demonstrating new products and bestsellers. Stop by their booths to visit experts to learn the latest applications in automation, robotics, software and machine controls, machinery and more. Learn new ways to increase productivity at North America’s largest metal forming, fabricating, welding and finishing event.

Beyond the three exhibition halls, keynote speakers and expert panels will cover topics such as AI, robotic technology, labor shortages and workforce development. There will also be FABx Tech Talks, Women of FABTECH and more. More details at www.fabtechexpo.com.

Speed to Market Matters: Manufacturer Shares how to get There Faster

The struggle to get products to market as quickly as possible isn’t new. Manufacturers have always battled against inconsistent quality and inefficient processes. But today, the battle is even harder to win. Competition is tougher, market conditions are volatile, and labor is scarce.

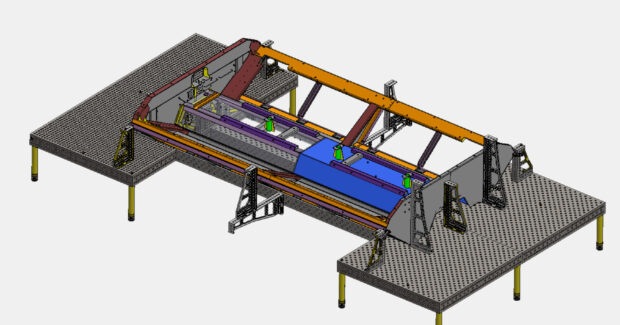

Across the board, manufacturers are being asked to do more with less. And because they’re stretched thin, they’re forced to use their limited resources to put out one fire after another while bigger issues are left smoldering. It’s a vicious cycle that ultimately puts cashflow and profits at risk. Luckily for manufacturers who’ve found themselves stuck in this reactive mode, Bluco® Corp. (Naperville, IL) is coming to Booth B33034 to break the cycle.

Bluco is uniquely positioned to provide exactly what manufacturers need right now: untapped reserves of efficiency and productivity. “In a sense, we’ve cracked the code,” said Bluco Sales Director Brian Dodsworth. “We see a pattern of companies actively looking for the right levers to pull to get over a hurdle, but they’re completely overlooking workholding. Once you understand that’s a lever you can pull, and then you add in the problem-solving expertise and modular toolset that only Bluco can provide, that’s where we change the game.”

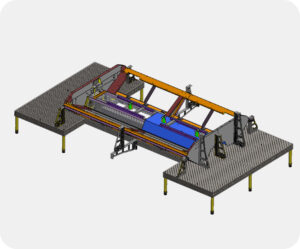

Bluco’s strategy enables three core capabilities for their customers: to move quickly; to adapt seamlessly; and to decide confidently. It’s a strategy that pays off for customers. Bluco’s booth will feature stories of customers who’ve shaved 50% off production time, reduced overall costs by 10%, achieved 7x greater accuracy, and finished parts a month faster.

Bluco’s process is unique in the industry. “People are used to choosing what they need from a catalog,” Dodsworth said. “But our process is different. When we assess a company’s needs, we take a step back from ‘I need a welding table,’ and identify what’s really holding them back.” Bluco creates solutions that give their customers a competitive edge. “By empowering them to manage change proactively,” Dodsworth said, “they can meet the demands of today’s market, and be prepared for whatever tomorrow brings.”

Saws and Ironworker Save Your Shop Time and Money While Increasing Production

AMADA MACHINERY AMERICA, INC. (Brea, CA) has more than 70 years of industry experience and is committed to helping customers deliver dependable service and top-quality work with exceptional sawing solutions. While AMADA MACHINERY takes great pride in its legacy, it is their drive and commitment to continuous improvement that sets them apart. AMADA MACHINERY works to achieve market-leading quality with reliable productivity. Stop by Booth A1114 to see and hear what their latest and greatest products are.

AMADA MACHINERY AMERICA, INC. (Brea, CA) has more than 70 years of industry experience and is committed to helping customers deliver dependable service and top-quality work with exceptional sawing solutions. While AMADA MACHINERY takes great pride in its legacy, it is their drive and commitment to continuous improvement that sets them apart. AMADA MACHINERY works to achieve market-leading quality with reliable productivity. Stop by Booth A1114 to see and hear what their latest and greatest products are.

On display, at the show, will be a few of the manufacturer’s industry leading Fabricating Vertical Tilt-Frame Saws. The VT4555M with cutting capacity of 18”-x-22” at 90° with a 1-¼” blade and the VT5063SW with cutting capacity of 20”-x-25” with a 1-½” blade. This saw will display a compact material handling system, with an infeed and outfeed table, showing off automatic material cuts. The saw will also showcase its Offline Program & Nesting software, making the operator’s job more efficient by being able to program thousands of parts and jobs offline. The blade that is specially designed for these Vertical Tilt-Frames is called the Eagle Beak VTR. The maximum pitch of this blade is two times the minimum pitch making the blade adapt well to various shapes and sizes. The Vertical Tilt-Frame line is backed by more than 110 years of unsurpassed performance, and is manufactured in Oshkosh, Wis.

AMADA MACHINERY will also feature a MSIW60D Spartan Ironworker. The Spartan Ironworker has five workstations, with LED lighting, and has the strongest stripper in the industry.

AMADA MACHINERY’s team has shown commitment and improvements in pushing the product lines to become their best versions. If you are looking to save time and money, while increasing production, then look no further. AMADA MACHINERY AMERICA keeps your best interests in mind while maintaining the philosophy of “GROWING WITH OUR CUSTOMERS.”

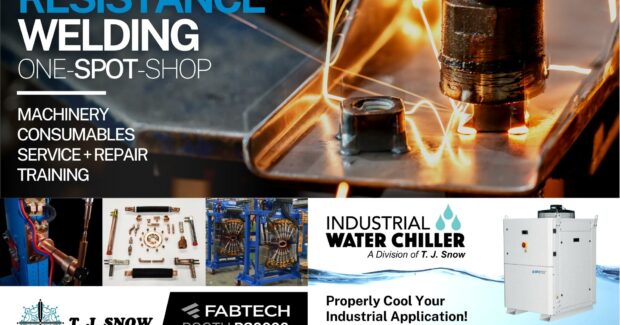

View the Latest in Resistance Welding Technology

T. J. Snow Co. (Chattanooga, TN), a leader in the specialized field of resistance welding machines and accessories, will exhibit a range of products in its large booth, Booth B30000, including:

• SlimLine dual-gun production spot welder with advanced HMI and T.J. Snow’s “Track & Trace” feature that documents weld quality.

• Size 2 MFDC press welder with Verifast Fastener Detection System.

• New-design heavy duty Rocker Arm Spot Welder with Entron EN6001 control and Unitrol’s “Soft Touch” pinch point operator protection system.

In addition to building its own line of resistance welders, T. J. Snow is a Master Distributor of TECNA® spot welders manufactured in Italy and imported by the container load to meet the demand for quick delivery of machines at attractive prices.

TECNA has a broad range of stationary and portable spot-welding machines, ranging from small foot-operated rocker arms to large press-type welders and hand-held spot-welding guns.

On display will be a 20 KVA air operated TECNA Model 4647 variable throat depth rocker arm spot welder that is ideal for most sheet metal shops. TECNA’s extensive product line of hand-held portable spot-welding guns will be represented by the new 90 KVA Model 3183, which features MFDC inverter technology.

Because most portable spot-welding guns are suspended from overhead, T. J. Snow will display TECNA’s broad range of spring balancers of various capacities. In addition to being used with spot-welding guns, TECNA balancers are popular in many different industrial applications, including assembly lines and food service.

Most resistance welders are water cooled and T. J. Snow has developed a complete line of self-contained industrial water recirculators and chillers, one of which will be on display. These chillers, which are often available from stock, can serve the water-cooling needs of a single machine or a complete plant.

Now in its 60th year, T. J. Snow Co. will continue its longtime tradition of helping customers succeed with the resistance welding process. T. J. Snow has launched a new online e-course to introduce welding operators to the world of resistance welding. At FABTECH, T. J. Snow will be giving away a limited number of All-Access Vouchers for customers to audit the new course.

Alkaline Cleaner/Inhibitor Combo Products to be Showcased

KYZEN (Nashville, TN), the global leader in innovative environmentally friendly cleaning chemistries, will exhibit in Booth D40743. The KYZEN Clean team will highlight their combination alkaline cleaners, METALNOX M6314CP and M6324CP.

The METALNOX products are innovative combination products that provide cleaning and corrosion protection in the wash and rinse stages of the parts washing process using only one chemistry. Both products clean effectively, boosting the parts cleaning process while providing long-lasting rust protection. If you are looking to simplify your cleaning process and streamline your chemical use, either of these products will get the job done.

METALNOX M6314CP is an aluminum-safe alkaline parts cleaner formulated to remove a range of manufacturing oils used in machining, stamping and deep draw operations. It is equipped with effective steel corrosion inhibitors to provide long-term protection for both mild and cast steel. With its advanced formula, M6314CP successfully prevents flash rusting, which is common in aqueous processing of ferrous metals. It is also suitable for use on non-ferrous metals, stainless steel, chrome steel, aluminum, magnesium and HSS-parts.

METALNOX M6324CP is a heavy-duty, alkaline cleaner that provides effective steel corrosion protection for a maximum of 90 days of indoor protection. It has an oil-splitting formula to allow efficient oil removal as well as difficult soils including carbon smut.

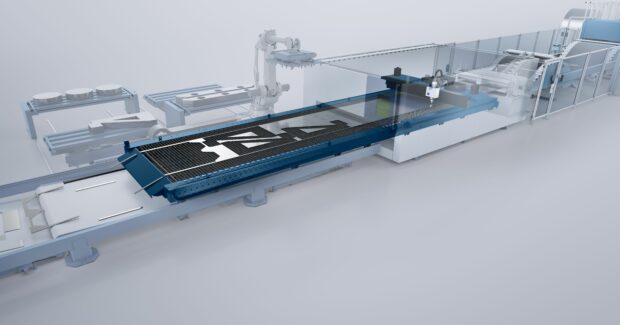

New Laser Blanking System Suitable for Flexible, High-volume Cutting Solutions

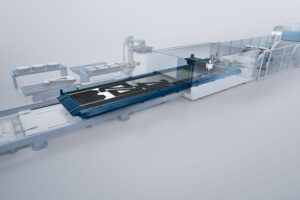

In Booth A2104, TRUMPF Inc. (Farmington, CT) will showcase the latest advancements in precision sheet metal fabrication and applications. One of the highlights in this year’s display is the TruLaser 8000 Coil Edition, a new laser blanking system suitable for any industry requiring flexible, high-volume cutting solutions. The system enables laser cutting and production “straight from the coil,” which saves up to 1,700 metric tons of steel annually and reduces costs.

The TruLaser 8000 Coil Edition can process up to 25 metric tons of coiled sheet metal from start to finish without any human intervention. It is an attractive option for companies interested in flexible, high-volume solutions for sheet metal fabrication, including automotive suppliers and automakers, electrical cabinet manufacturers, elevator producers and HVAC manufacturers.

“The TruLaser 8000 Coil Edition is another solution from TRUMPF that helps North American customers to join the drive toward greater sustainability in manufacturing while simultaneously boosting efficiency,” said Salay Quaranta, TRUMPF Inc. Head of TruLaser 2D. “Compared to conventional laser cutting machines, this setup allows companies with high volume manufacturing to save up to 1,700 metric tons of steel a year, which can equate to saving approximately 4,000 metric tons of CO2 and reducing material costs.”

TRUMPF’s new laser blanking system helps companies enjoy the benefits of laser processing even in high-volume production environments. “Volume manufacturers often use die presses for blanking operations, but that means they need to adjust or even replace the tool whenever they make the slightest modification to their components, ultimately costing time and money,” Quaranta said. “Many industries are seeing significant reductions in the scale of individual production runs, which makes modifications even more costly and time intensive. The laser allows users to carry out modifications without a new tool, so it’s much easier, faster, cheaper and more flexible.”

TRUMPF is a high-tech company offering manufacturing solutions in the fields of machine tools and laser technology.

Discover and View Innovative Fabrication Solutions

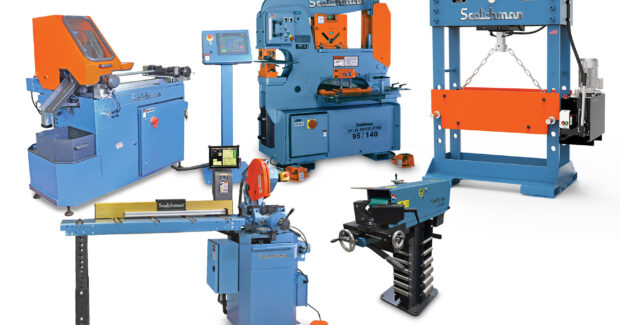

Scotchman Industries, Inc. (Philip, SD) invites you to stop by either Booth A3431 or Booth A3531 for live equipment demonstrations to discover innovative fabrication solutions using the company’s range of general to heavy-duty metal fabrication machinery.

Cold Saws:

• CPO 350 w/Digital Quick Stop Measuring System – 14” manual cold saw with digital length gauge.

• CPO 350 PKPD VS – 14” variable speed semi-automatic cold saw.

• CPO 350 AutoLoader – fully automatic sawing system with bundle loader option.

• CPO HFA CNC – hitch feed automatic saw CNC for unlimited cut length settings.

• SUP 600 AngleMaster – large capacity precision upcut nonferrous saw. Combines an automatic mitering ability with a programmable feed.

• GAA 500 CNC DT20 – precision CNC controlled upcut automatic saw for cutting nonferrous at 90° with 20 mm drill tap.

Scotchman Ironworkers:

• DO95 American made dual operator ironworker has a hydraulic system designed with two pumps for two-person simultaneous operation. Also includes a 95-ton capacity punch and a 9” throat depth, which can punch a 1-3/16” hole in 1” material, a 24” flat bar shear, rectangle notcher, angle shear and tool table.

• 5014-ET Ironworker, the world’s first and only 50-ton hydraulic ironworker with a revolving three-station turret punch. A revolving turret accepts up to three different punch sizes that can be changed in seconds. This American made hydraulic ironworker features 50 tons of pressure and can punch a 13/16″ hole in a 3/4″ plate. Other workstations include a 14” flat bar shear, rectangle notcher, angle shear and tool table.

• FI85 – 85-ton ironworker with five fully integrated workstations.

• 50514-EC w/Automated Measuring System – 50-ton ironworker coupled with an automated measuring system.

Range of New Technologies Enables Competitive Welding Operations

Airgas, an Air Liquide company (Radnor, PA) will showcase innovation for the automation, welding, and cutting industries from Booth B20020. Airgas’ booth will highlight a full range of new technologies, products, and services to help customers stay competitive and drive efficiencies, including:

RADNOR™ Plasma Cutting Table: Airgas’ robust plasma cutting table provides industrial strength in a compact footprint, with easy setup and is ready to ship. Available in 4′-x-4′ and 4′-x-8′ options, this table includes FlashCut® software and robust motors, gear boxes and helical gear racks typically used on high-end larger systems.

BotX Welder™: The BotX collaborative robot welding system addresses the skilled labor shortage by enabling companies to quickly acquire easy-to-use automated welding through short or long-term rental, lease or purchase programs. In just a few hours, users can learn how to easily train and operate this cobot system from RedDArc.

ARCAL™ Welding Gases: The ARCAL line includes five ready-to-weld pure argon and argon gas mixtures and provides welders with high quality shielding gas that allows them to produce better welds. ARCAL gas cylinders are equipped with SMARTOP™ and EXELTOP™ valves to help improve productivity, lower operating costs, and create a safer work environment.

RADNOR by 3M™ Speedglas™ welding helmets: These professional-grade helmets offer durability, comfort, and the rugged reliability and value of the RADNOR brand with the performance technology of the 3M Speedglas brand.

One-stop Source for Metal Fabrication Machinery

Roll. Punch. Form. Shear. Automate. Better. Trilogy Machinery, Inc. (Belcamp, MD) is a nationwide leader in metal fabricating machinery and the exclusive distributor of top global brands such as Sunrise, SweBend, Lemas, Synergy and BSP.

Stop by Booth A4567 to learn about the latest innovations in metalworking machinery and enjoy live demonstrations of a full range of equipment — including ironworkers, bending rolls, processing lines and more.

Whether you’re a small-scale workshop or a large manufacturing facility, we’ve got a machine to fit your needs. Count on our knowledgeable team to understand your business, recommend a solution, and support you throughout the lifespan of your purchase.

See the Latest in Powder Coating Technology

Gema USA Inc. (Indianapolis, IN) will conduct demonstrations of the Dynamic Contour Detection Laser Scanner, designed to detect object geometries, aligning each gun to the correct position to coat the most complex components. Also on display will be Gema’s cloud-based digital intelligence tool, GemaConnect®, providing data on performance and operational status, as well as maintenance and system health information. Try out firsthand the OptiFlex® Pro manual spray unit, featuring the highest charging power in the industry at 110,000 V/110 µA. Visit Gema in Booth D40311 and find out about the latest developments in automatic and manual powder spray guns, booths and powder management technology.

LS7 Laser Cutter Demo Coupled with Automation System

In Booth A1338 BLM GROUP (Novi, MI) will demonstrate its LS7 laser cutting machine, the latest sheet laser in its lineup, which will be coupled with an automated load/unload system. The LS7 is available in laser powers up to 12 kW and can cut steel, stainless steel, iron, copper, brass, and aluminum in thicknesses from 0.20”-to-1.57”, or even double sheets, depending upon the material and selected laser power. It is available in two versions – the 3015 with a maximum sheet size of 121.5”-x-62.2” and the 4020, capable of handling sheet sizes up to 162.5″-x-79.5″.

The LS7 offers an axis acceleration of up to 2g to optimize processing cycles and minimize down time. Plus, the fully electric pallet change helps to increase productivity by up to 9%, with an average of 10 pallet changes per hour. It only takes a few seconds to extract the laser-cut parts and load the new sheet metal. Because the handling is fully electric, without pneumatic or hydraulic actuators, the LS7 also offers improved maintenance and energy usage. These features, in combination with the ability to use laser power up to 12 kW, makes the LS7 a highly productive machine.

Automatic sheet loading and unloading is also available for the LS7, which can accommodate one or two storage towers for automated material type and thickness changeovers, which is especially well-suited for unmanned operations.

Other features of the LS7 include plug & play operations that lead to fast and easy equipment setup, the ability to integrate with ERP systems, as well as material handling and storage systems, leading to better interconnectivity. The system also comes equipped with the company’s patented Active Tools, which automatically adapt process parameters for optimal results independent of operator experience, ensuring the highest cutting precision and speed.

Importantly, the system is built in a way that enables extremely quick installation.

New Line of 1.3 HP Air Tools Features Right Angle Grinders and Sanders

Dynabrade Inc. (Clarence, NY) introduces a new line of 1.3 HP Air Tools. Dynabrade will be in Booth B13045. These new high quality air tools are available as a Right-Angle Disc Sander and a Right-Angle Depressed Center Wheel Grinder.

Available in 4”, 4-1/2” and 5” diameters, the tools are excellent for fast stock removal, metal clean up prior to welding, removal of weld beads and various material removal applications. The Depressed Center Wheel Grinder is available in either 12,000 rpm or 13,500 rpm. The grinder is ideal for use with Type 27 grinding wheels. The 1.3 Hp Disc Sander, available in 12,000 rpm, is for use with a variety of coated abrasives.

The tools feature a governor assembly for maintaining rpm under load. Also included is a safety-lock throttle to prevent accidental startup and a spindle lock for fast, easy abrasive/wheel change. A two-position side handle for left or right-hand use is included. This vibration-dampening handle also reduces vibration to the operator’s hand. This line of air tools was also designed with a wick lubrication system, which extends gear life when the tool is properly lubricated with gear oil. Also included is a 360° rotational exhaust for directing the exhaust away from the operator. The Depressed Center Wheel Grinder also includes a safety guard and wheel flange kit; 3/8”-24 and 5/8”-11 spindle models are offered. Made in the USA.

Come Interact with the Power of Industrial Grade Lifting Magnets

strength in a lightweight, compact package.

Industrial Magnetics, Inc. (IMI) (Boyne City, MI) invites you to Booth A2979 to feel the raw power, durability, and superior design features of our many industrial magnetic products. Experience the difference firsthand as with magnets, feeling is believing. IMI will feature many Mag-Mate® brand products like our top selling PowerLift® magnets, our best-in-class series of FX and FXE permanent magnetic lifts, among other handy, industrial grade lifting magnet solutions. IMI will also display a fan favorite, the Kant-Twist® brand cantilever clamp line up. Don’t miss a chance to gain some knowledge on the Kant-Twist, a well-known social media sensation of the fabrication world. IMI will also showcase our versatile line up of magnets for welding, hot plate/parts handling, and everyone’s favorite interactive display of the RapidFire® Retrievers.

With solutions listed above for under the hook, on the welding bench and in the workshop, we must not forget IMI also offers solutions for automated application, including our family of Transporter® magnets for lifting and shuttle applications, Sheet Fanners to separate oily or sticky steel blanks and formed parts, and Magnetic Conveyors for sheet and parts transfer systems.

We look forward to meeting you face-to-face at the show. Our expert sales staff and marketing staff will help you select that perfect standard off-the-shelf solution, or start the process of creating a unique, custom engineered solution to meet your specific needs. At IMI we love a challenge, and our customers’ unique requirements drive our innovative spirit. Our slogan is “Making Things Better,” but with our products and your skills, you’ll be “Making Things Great.”

Cutting Solutions Manufacturer to Unveil Cutting-edge Products

Cosen Saws (Charlotte, NC), a global leader in the manufacturing of premium industrial cutting solutions, will showcase its industrial metal cutting band saws at Booth A5126.

Attendees can expect an unparalleled experience at the Cosen Saws booth, where they can explore an impressive array of advanced cutting solutions designed to optimize production processes, increase efficiency, and deliver superior performance. With a strong commitment to innovation and quality, Cosen Saws is at the forefront of the industry, constantly pushing boundaries to meet and exceed customer expectations.

Cosen Saws will showcase new and original band saws at its booth. Cosen Saws offers a comprehensive range of high-precision band saws designed for a wide variety of cutting applications. With advanced features such as automatic feed systems, adjustable cutting angles, and digital displays, these band saws provide unmatched accuracy and efficiency. The CNC band saws are equipped with state-of-the-art technology, enabling automated and precise cutting operations. With user-friendly interfaces, customizable cutting programs, and advanced control systems, these saws ensure optimal efficiency and accuracy. Cosen Saws will also display part of their vertical saw lineup which offers versatile cutting capabilities, allowing operators to make precise cuts effortlessly. These saws feature robust construction, ergonomic design, and intuitive controls, making them ideal for a range of industries and applications.

Visitors to the booth can also interact with our team of experts, who will be available to provide in-depth product demonstrations, answer questions, and discuss specific cutting needs. There will also be live cutting demonstrations which will showcase the speed, precision, and reliability of our cutting solutions firsthand.

Subscribe to learn the latest in manufacturing.