What’s New in Tool Presetting?

Learn all about the latest tool presetters that will ensure your product is within specifications before the tooling process starts.

Posted: June 16, 2023

Presetting tools maximizes the rates of your productivity and uptime. Suppliers continue to conduct research to reduce the time it takes to preset tools, while ensuring higher measurement accuracy and precision.

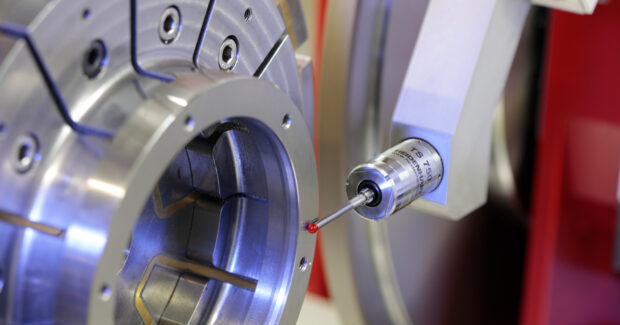

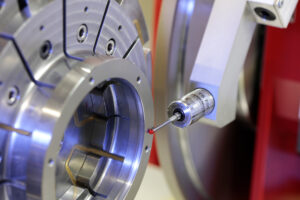

Reliable and Proven Tool Setting Probes

Blum-Novotest, Inc. (Erlangen, KY) offers the Z series (Z-Nano and Z-Pico), which are tool setting probes with a linear working principle for monitoring the smallest tools. They are economic solutions for fast tool breakage detection and highly precise length measurements in machine tools. The wear-free optoelectronic measuring mechanism with the linear working principle provides the highest reliability under the most adverse manufacturing conditions.

The ZX-Speed series consists of 3D tool setting probes for precise tool measurement and breakage detection. The series is comprised of universally applicable probes for the measurement of length, radius, and tool breakage in the machining center. The probes use a modern, optoelectronic measuring mechanism, which is unparalleled in its precision and longevity.

Tool setting probes from Blum are available with cable, radio or infrared technology.

Universal Presetting Machines with Integrated Tool Heat-shrinking System

The ZOLLER (Ann Arbor, MI) redomatic series provides a unique, two-in-one solution that combines a universal presetting and measuring machine with an integrated tool heat shrink system to maximize efficiency in high-volume and high-speed manufacturing.

The redomatic meets tolerances required for multi-spindle CNC machines and guarantees tool lengths are preset within 10 microns, thanks to the automatic length setting system in the Z-axis. A high-precision spindle ensures different toolholder interfaces are clamped with micron-precise accuracy.

The redomatic 400 accurately measures tools with lengths up to 23.62” (600 mm) and diameters up to 24.4” (620 mm), while the redomatic 600 measures lengths up to 39.4” (1,000 mm) and diameters up to 31.5” (800 mm). Safety is paramount at ZOLLER, and that’s why machines in the redomatic series are certified by TÜV SÜD to meet UL/CSA safety standards.

A recent redesign of the redomatic deployed the latest heat shrink technology to consistently heat and cool a tool in less than 60 seconds, which reduces machine downtime, limits wear on toolholders and drives down energy consumption. It uses up to 30% less electricity than prior models.

ZOLLER has also revamped the induction coil where two parallel windings can be controlled separately to optimize energy usage for that toolholder, and the shielding system automatically adjusts up to a shank diameter of 1.25”. Cooling bells that accommodate shrink-fit toolholders from 0.25-to-1.25” expedite the cooling process.

Tool Presetting Machine Reduces Setup Time by up to 70%

HAIMER USA, LLC’s (Villa Park, IL) Microset VIO linear tool presetting machine improves your machine utilization by reducing setup time by as much as 70%, increasing machine uptime. Using an optical camera for measurement ensures higher accuracy and extends tool life. Eliminating manual entry of offsets reduces errors caused by operator mistakes. Achieve efficient, accurate, and reliable results with this tool presetting machine.

Leverage In-process Workpiece Monitoring

HEIDENHAIN (Schaumburg IL) introduces the new TS 760, a more accurate variant of the familiar TS 460 workpiece touch probe with cleaning jets and EnDat support. The TS 750 was developed specifically for in-situ workpiece inspection in grinding applications.

The TS 760 is a high-accuracy workpiece touch probe with an accuracy of ±1 µm (with the T434 standard stylus). It offers high probing reproducibility of 2 σ ≤ 0.25 µm. The signal transmission is radio and infrared (at same time as tool touch probe.) There are minimal probing forces, Finally, it features HTL or EnDat 2.2 (via transceiver) interfaces.

The TS 750 is a workpiece touch probe for grinding machines and lathes. It offers high probing accuracy of down to ±1 µm (with the T434 standard stylus). There is a high probing repeatability for very high measurement quality down to 2 σ ≤ 0.25 µm. Signal transmission is via cable, and the interface is HTL. The probing speed is 1 m/min. The protection rating is IP68.

Thermal Stability coupled with High Precision

Elbo Controlli Tool Presetters (a brand of Lyndex-Nikken, Mundelein, Ill.) combine the best of both worlds for thermal stability and optical precision. This combination provides the highest level of repeatability and reproducibility, ideal for most tool measuring and inspecting. The presetters incorporate custom optical scales and vision systems that are geared for measuring and inspecting cutting tools.

An addition to the offering of presetters is the newly designed E346+/E346V+, which delivers the punch of larger, more sophisticated presetters, but in a smaller footprint.

The E346+/E346V+ features a new larger 15” TFT LCD Touch Screen that provides full operator control via an intuitive icon system. Also included as standard is the capability to inspect the cutting edge. Includes up to 9,999 machine tool origins and up to 999,999 tool table capacity.

With the incorporation of the TID (automatic Tool Identification System), Elbo Controlli presetters offer a direct connection to a two-way communication between the presetter and CNC. Measurements are sent directly to the CNC without downtime. TID can acquire tool data from the CNC offset table. Unlike other presetters on the market, all software updates are free for the life of the presetter.

Compact Optical Tool Setter for Small Applications

Marposs Corp. (Auburn Hills, MI) has expanded its VTS (visual tool setter) family with the VTS SF-45 Compact, suited for non-contact, optical measurement of small, complex-shaped tools in constrained working spaces such as micro-machining, semiconductor or other applications. The VTS SF-45 units are installed inside the machine working area, monitoring actual tool working conditions without any contact while the tool rotates at full spindle speed (up to 80k rpm) during data acquisition. Since there is no need to slow the spindle, pre-setting time is reduced and measurement accuracy increased to better eliminate collision hazards.

The VTS SF-45 acquires a variety of tool dimensions in a single instant using the principle of shadow projection where an illuminated object projects its shadow onto the camera. These measurements include tool length, static and dynamic tool diameter, the tool run-out and cutting-edge radius. With a resolution of 0.1 µm, the VTS enables measurement of tools with diameters as small as 10 µm with repeatability of 0.2 µm, providing a higher level of accuracy than touch probes or lasers in small applications.

The GUI software simplifies the measuring cycle process and documents the tool history, helping to quickly reveal damage in advance of the machining operation. The software can be integrated into Marposs touchscreen PCs or in a standalone version for PCs with Windows or Linux.

Subscribe to learn the latest in manufacturing.