Sheet Metal Knowledge at the Push of a Button

Potential recognition, feasibility check and part optimization for sheet metal processing.

Posted: July 21, 2023

A cloud-based web app solution for analyzing and optimizing sheet metal parts aims to give sheet metal fabrication more process reliability in manufacturing. One automated potential recognition and AI-based part optimization with an integrated redesign is so far unique on the market and supports the digitalization process on the way to Industry 4.0 and the Smart Factory. In the future, further web shops and marketplaces are to be connected.

To ensure that bending does not turn into breaking, a great deal of know-how is required in sheet metal processing. However, this is mostly in the minds of experienced sheet metal specialists who are gradually retiring. With the departure of the know-how carriers, the wealth of experience gained over many years is disappearing.

Stuttgart, Germany-based start-up Optimate is one company that is digitizing the sheet metal knowledge that has been built up over decades. This is a real challenge considering how extensive and diverse the applications are in sheet metal processing. “We have recognized this problem and wanted to hold decades of knowledge and access to sheet metal expertise as a ‘digital consulting service,’” recalled Optimate CEO and co-founder Jonas Steiling. This initial vision has since become reality with a digital solution for the analysis and optimization of sheet metal parts. Those using the solution no longer have to run the risk of bringing a part into production that may not be possible to manufacture at all or only at high cost. “Not only do we give design and work preparation more process reliability, but time-consuming queries with the customer and expensive, manual redesigns are now a thing of the past,” Steiling said.

Analyzing Parts via Cloud-based App

The cloud solution consists of two products: the feasibility check and the part optimization. In a first step, the user uploads his sheet metal part as STEP or SolidWorks format in the cloud-based web app. Multiple 3D CAD files can be uploaded and analyzed simultaneously. Structural steel, stainless steel and aluminum can be selected as material options. Within a few seconds, the potential of each part is listed. A highly optimizable part can mean cost savings of more than 30%, a part that can be optimized well can lead to cost savings of up to 20%. “The user now sees optimization opportunities where he previously had no transparency about his parts and where it is worth taking another closer look,” Steiling said.

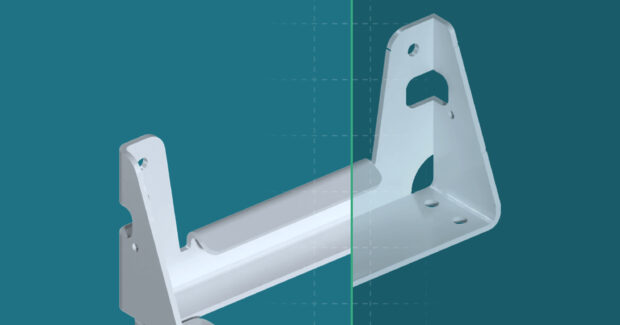

The service recognizes the optimization potential within seconds and indicates any design errors. Parallel to the potential detection, a feasibility check runs in the background to ensure that each part can also be manufactured in a process-safe manner. If this is not the case, the corresponding areas on the part are marked in color as warnings. While deformations often affect the part’s appearance, a large proportion of the warnings issued prevent the worker in production from being able to manufacture this part at all. If, for example, the minimum flange length is not reached and the marked error leg is too short depending on the bending angle, sheet thickness, material and tool pairing, then the leg cannot be bent. The designer can thus be informed as early as possible about the warning or other interfering contours, which are marked in red in the 3D graphic. (See the mesh plate with undercut flange length figure.)

Part Optimization at the Push of a Button

But what is the use of warnings if they have to be corrected manually? The highlight of Optimate’s solution: at the push of a button, a design proposal for the process-safe production of the part is made immediately. “With one click, an optimization graphic displays an extended leg to the minimum flange length,” Steiling said. The advantage is that the designer and the work preparation staff can always have the actual state displayed parallel to the optimized target state. The users can now download the adapted part directly as a STEP or SolidWorks file and transfer it to their CAD program. For the whole thing to work, the existing bending tools must be initially entered in the individual customer profile. This prevents optimization proposals from being made for which no required toolset is available.

AI with More Than 90% Accuracy

Artificial intelligence has been developed to identify the optimization potential. The AI algorithm contains nearly 60 different features that can describe pretty much any sheet metal part. “In the meantime, we can predict with 92% accuracy whether there is potential for optimization, even for parts that the AI has never seen before,” Steiling said. And the more users upload their parts to the cloud solution, the “smarter” the AI eventually becomes. “We want to keep training the AI so that the accuracy of the hits keeps growing,” Steiling said.

What about the remaining 8% of the route? If users reach the limits of what is possible, they can click on “Consulting Services” in the cloud platform for assistance.

AI Always Recognizes the Optimization Potential

efficient design variants; below left the part as originally planned with stabilizing welds;

below right without welding with relief cut on the rear wall.

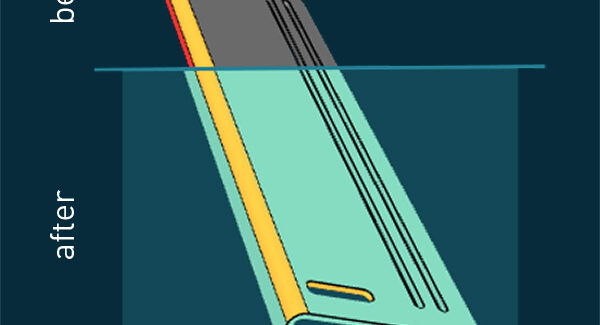

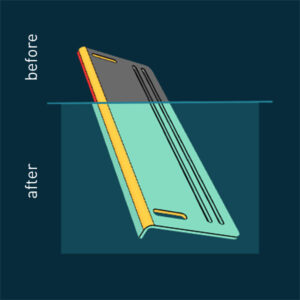

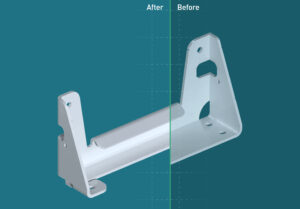

Often the feasibility check does not detect any warnings, i.e., the analyzed part can in principle be manufactured in this way. The AI, on the other hand, recognizes a high potential for optimization. So why not optimize when this can often eliminate entire production steps and make enormous cost savings possible? The question now is: How can this sheet metal part be redesigned with system support? A clever solution has been developed: automated optimization. Matching CAD parts can be uploaded very easily. In the background, the 3D body is unfolded into a 2D representation. This unfold is then transferred into a graphical description in which each surface has a connection type to its neighboring surfaces. On these graphs, the solution generates alternative design methods for the part and displays the most relevant ones. A stability check and a cost calculation are automatically run for each of these solution variants. (See the example of sheet metal bracket.)

In addition to the original part uploaded by the customer, there are design variants to eliminate the initially designed expensive weld seam by replacing it with a bend. The original weld becomes a bend, the base is provided with a separating cut. The part now gets its stability from the mounting situation and no longer from the weld seam. The welding process can be completely eliminated and thus an entire work step can be saved, which results in cost savings of more than 40% for the bracket.

“If such a part is then produced in larger batch sizes, the cost savings are even more significant,” Steiling noted. The platform will then also display the unfolded version of this part. In the 2D unfold, the weld seams are shown in orange, the bends in green and the inner and outer contours in white lines. Also, the material waste is displayed as it can play an important role for the cost calculation.

The users in the design or work preparation department select the most suitable one for them from all five suggested variants with a click. The selected optimized variant appears on the screen with an indication of the cost saving, showing exactly where this is achieved. “The final decision should still lie with the designer,” Steiling said. “We provide the basis for the designer’s decision, including a redesign and CAD data set. With our tools, the designer has access to extensive expert knowledge on all aspects of sheet metal processing and we thus expand the respective decision-making horizon in the long term.” When the client finally agrees to the part optimization and redesign, the optimized parts can go into production with process reliability.

Connecting Web Shops and Marketplaces

Suppliers are also aware of this problem. It is not unusual for a customer to order a part for which a price has already been calculated, even though it cannot be produced at all. Web shop operators in particular have a great interest in integrating an automated feasibility check in order to ultimately be able to rule out the possibility of faulty parts entering production in the first place.

In the meantime, Optimate has already been able to connect various web shops in the supplier environment directly to the cloud solution via the API interface. The start-up also has its sights on all marketplaces for sheet metal parts.

Although the initial focus is on marketplaces for sheet metal parts and sheet metal fabrication, marketplaces for machining are to follow in a second step. “For example, if a 3D printing marketplace operator decides to include and offer sheet metal technology, our tools make it easier to build up sheet metal know-how,” Steiling said. “In addition, with each additional user, web shop and marketplace, more data is available to the AI, making our knowledge database for sheet metal processing increasingly smarter.”

Subscribe to learn the latest in manufacturing.