FABTECH 2023 – Welding, Welding Automation, Robotics & Industrial Automation

Hall B: Welding, Welding Automation, Robotics & Industrial Automation of FABTECH 2023, North America’s largest metal forming, fabricating, welding and finishing event.

Posted: July 23, 2023

Welding, Welding Automation, Robotics & Industrial Automation (Hall B)

Fabricating & Metalworking is proud to present the FABTECH 2023 Product Showcase, which is an invaluable guide to navigating the trade show floor at McCormick Place in Chicago this September. This FABTECH section outlines some of the products and demonstrations expected to be on display by more than 1,500 world-class suppliers in three exhibition halls. An estimated 45,000 people will attend FABTECH 2023.

Pavilions at FABTECH are dedicated to 3D/Additive Manufacturing, Forming & Fabricating (Hall A); Welding, Welding Automation, Robotics & Industrial Automation (Hall B); and METALFORM, Finishing, Tube & Pipe (Hall D). This article is dedicated to: Hall B– Welding, Welding Automation, Robotics & Industrial Automation

Bernard and Tregaskiss to Showcase MIG Welding Solutions

Bernard (Beecher, II.) and Tregaskiss (Windsor, Ontario) will attend FABTECH sharing Booth B23027 with Miller Electric Mfg. LLC and Hobart Brothers LLC. The companies will showcase integrated welding solutions that help improve productivity, reduce costs and deliver high quality.

Bernard will display its AccuLock™ S consumables with dual-locked and conventional liners for semi-automatic welding applications. Tregaskiss will showcase its AccuLock R and AccuLock HDP consumables for robotic applications. These consumables systems are designed to increase consumable life and productivity while decreasing costs.

Also at the booth, Tregaskiss will display its TOUGH GUN® TA3 robotic air-cooled MIG guns as well as TT4E and TT4A nozzle cleaning stations, which automate spatter removal to extend robotic MIG guns and consumable life.

Tregaskiss will also display its BA1 cobot air-cooled MIG welding guns, designed for Miller® Copilot™ Collaborative Welding Systems. The cobot gun offers fast, simple installation and consistently delivers high-quality welds. Bernard will feature its BTB semi-automatic air-cooled MIG guns. Operators can customize these guns with multiple handle, trigger and liner options along with fixed or rotatable neck and choice of consumables, using the online configurator. Clean Air™ fume extraction MIG guns, which reduce smoke at the source, also will be featured by Bernard.

Representatives from Bernard and Tregaskiss will be available to answer questions about the brands’ welding solutions and provide information on technical and product support.

Hands-on Demonstration of Cobot, Heavy Industrial Systems and Battery Welder

What can you make possible with ESAB® (North Bethesda, MD)? Find out with hands-on and static demonstrations of ESAB’s newest manual and automated welding and cutting equipment, filler metals, PPE and software applications in Booth B20063.

Exhibit highlights include:

- Hands-on programming demonstrations of the ESAB Cobot that prove it takes just seconds to teach welding paths using a software app that runs on a standard smart phone or tablet and a “Smart Puck” to hand-guide the torch. Creating a weld sequence is as simple as creating a song playlist. The ESAB Cobot costs a fraction of a pre-engineered robot cell, does not require a programmer, and deploys in a matter of hours. The ESAB Cobot gives small- and medium-sized fabricators the freedom to automate high-mix, low-volume applications while improving productivity 200%-to-400%.

- Live arc demonstrations of the next-generation Warrior® Edge, a 500A multi-process pulsing power source paired with the RobustFeed Edge wire feeder. Warrior Edge can detect and react to arc behavior up to 10 times faster than traditional inverter machines. Synergic control and quick job buttons enable regular welders to achieve excellent welding results without a complex setup process. It also has built-in connectivity and comes with a subscription to the InduSuite WeldCloud Fleet online software application. RobustFeed Edge also features a new digital gas control technology called TrueFlow that improves welding quality, saves gas and helps avoid weld defects caused by improper flow rates.

- Hands-on welding with the Renegade™ VOLT™ ES 200i Stick/TIG battery-powered welding system, which ESAB developed in conjunction with Stanley Black & Decker. Powered by four DEWALT® FLEXVOLT® 12 Ah (amp-hour) batteries, Renegade VOLT can weld up to 30 stick electrodes or TIG weld for 50 minutes on a single battery charge. Renegade VOLT offers maximum welding output of 150A on battery power. It also connects to 115/230V AC primary power and provides a maximum welding output of 210A on 230V primary.

- The Victor® oxy-acetylene torch cutting contest enables visitors to test their speed and skills.

New Portable Continuous Duty Unit for Weld Fume Extraction

The new FumeVac FV-190SC-1 and FV-190SC-2 from Hastings Air Energy Control, Inc. (New Berlin, WI) offer multiple options to control weld fume emissions. Hastings Air Energy Control will be in Booth B33060. The FV-190SC-1 is designed to operate a single ErgoMax weld fume extraction MIG gun. The FV-190SC-2 is designed to operate two ErgoMax guns. The units provide long-term service for continuous duty welding applications, unlike the high-speed brush-motor designs commonly found in the industry today. The units come standard with a unique vibration/compressed air-base manual filter cleaning system to improve filter life and performance.

The FV-190SC series of fume extraction systems are unique in the industry, with their elevated vacuum levels, functionality, lightweight, portability and engineering quality. The unit can also be remotely controlled for on demand extractions.

Features and benefits:

- Designed for fume extraction up to 115+ CFM at the gun 195+m3/hr.

- Multiple versions to accommodate either one or two fume guns, or for more demanding automated or robotic welding applications.

- Maintenance-free, high-performance brushless motors.

- Low noise level 78dB @ 5’.

- Motor thermal and electrical overload circuit protection and indicator light.

- Three-step motor speed control for variable vacuum levels as needed.

- Auto/manual mode switch for on demand or continuous operation.

New Robotic Plasma Cutting Machine, and Pipe Profiler on Display

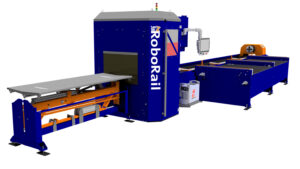

HGG Profiling Equipment BV (Houston, TX), a leading manufacturer of cutting and profiling equipment for the welding industry, will be exhibiting its ProCutter 900 RB Pipe Profiler in Booth B13051. The recently introduced RoboRail robotic plasma cutting machine will be featured in our partner Automated Layout Technology’s Booth A5716.

The ProCutter 900 RB integrates the proprietary ProCam software for 3D parameter-based part profile programming for perfect fit up. A three-jaw chuck for secure pipe positioning, durable pipe support, and a cutting bed equipped with a roller bed offer easy pipe loading and unloading. Available with a cutting trolly with biaxial cutting head for efficient oxyfuel plasma cutting, the system’s easy-to-use operator interface with touch-screen navigation simplifies the training process.

The RoboRail has been proven to significantly reduce profile cutting time by up to six hours in some applications including pipe for railings, channels and other miscellaneous parts. The compact robotic machine’s ability to take designs directly from 3D SDS/2, TEKLA, STEP, and other CAD files ensures the most accurate cutting performance for channels, tube columns and angles up to 8”-x-8”, and 1-¼” pipe. The Hypertherm plasma cutting system processes handrail pipe, stringer channels, box tubes, angles, etc., with ease.

At the show, HGG will feature the Imperial measurement version of the RoboRail system, which features an infeed length/weight up to 882 lbs. and outfeed length up to 8’ maximum with an outside diameter of 10.79” and minimal flat bar thickness of 0.40”. One customer reduced pipe profile cutting time from several minutes manually to 30 seconds after adopting the automated RoboRail system, including layout and marking. The system’s cutting accuracy eliminates the need for grinding and sawing and shaves significant time off welding processes. Visitors to the booth will be able to speak with automated 3D plasma cutting experts who will be available to discuss additional automated 3D profile cutting systems suitable for virtually any industry.

Represented exclusively in the United States by Automated Layout Technology, RoboRail is suitable for supplementing larger capacity machines for added processing flexibility to cut copes and cut-outs quickly and accurately in angle, single-story tube columns for strip malls or mezzanines, bolted stairs, and 8” or 10” structural pipe.

Industrial Cutting Products and Software Ensure Increased Productivity and Profitability

Hypertherm Associates (Hanover, NH), a U.S.-based manufacturer of industrial cutting products and software, is gearing up for FABTECH 2023. The combined booth of Hypertherm and OMAX technology brands, located at Booth A4531, will provide visitors with a comprehensive range of plasma and waterjet products. Attendees will have the opportunity to witness X-Definition® plasma robotic cutting using Robotmaster® software and the HPR® cartridge for HPRXD plasma systems. Hypertherm Associates will also showcase demonstrations of their software solutions, including Robotmaster offline programming for cutting, welding, trimming, polishing, and other robotic applications.

Booth B15009 will feature the Powermax® air plasma products, including the innovative Powermax SYNC® plasma with built-in intelligence and a single-piece consumable cartridge. Attendees will have the opportunity to experience the Powermax SYNC and its SmartSYNC® torch firsthand. They can also meet Rae Ripple, a metal artist, TV personality, and author, who will demonstrate plasma cutting best practices.

“We are thrilled for FABTECH 2023 in Chicago,” said Kristy Gerwig, who is managing this year’s show for Hypertherm Associates. “We can’t wait to work with our partners in helping customers find the right technology to suit their needs and discuss how our plasma, waterjet, and software products can support their business goals.”

Hypertherm Associates is a U.S.-based manufacturer of industrial cutting products and software. Its products are used by companies around the world to build ships, airplanes, and railcars; construct steel buildings, fabricate heavy equipment, erect wind turbines and more. In addition to cutting systems, the company creates CNCs, and software trusted for performance and reliability that result in increased productivity and profitability for hundreds of thousands of businesses. Founded in 1968, Hypertherm Associates is a 100% associate-owned company, employing approximately 2,000 associates, with operations and partner representation worldwide.

A Range of Abrasive Solutions for a Smart User Experience

Saint-Gobain Abrasives (Worcester, MA), one of the world’s largest abrasives manufacturers, has announced that at FABTECH it will feature how to “Work Smart with Norton” by exhibiting a range of abrasives that optimize the user experience. At Booth B35007 Norton will highlight the latest in grinding, cut-off, blending and finishing solutions to address today’s challenging application requirements. The company also has ways to increase user productivity by automating grinding processes. Norton established the new Abrasive Process Solutions (APS) Program to help customers determine the optimal grinding or finishing solution for the application at hand, ranging from simple to complex, off-hand or automated, and for metal fabrication, production grinding and virtually any abrasives operation.

Norton continually researches, designs and manufactures abrasives, as well as offers grinding application guidance, by prioritizing the user experience. Abrasives to be highlighted include:

- New Norton Vortex® Rapid Prep Non-Woven Flap Discs that last longer and produce significantly increased cutting rates and smear-free finishes simultaneously. Norton patented Vortex agglomerated aluminum oxide grain technology enables the cutting power of a coarser grit while producing a finer finish in one abrasives disc solution.

- New Norton Vortex Rapid Blend Coarse Grit Wheels and Discs offer a finishing process solution that reduces and blends welds in a single operation, providing a 30%-to-50% improvement in productivity, while leaving smear-free finishes.

- Norton QUANTUM3™ Line of Grinding and Cutting Wheels cut fast and sharp, achieving increased metal removal in less time, with less operator fatigue to significantly increase grinding output and lower costs. The wheels feature a proprietary grain along with a tougher bond system containing a unique combination of fillers and bonding agents.

- Norton BlazeX F980 Fiber Discs have premium ceramic alumina micro-fracturing grain and proprietary COOL FRICTION technology, resulting in more parts per disc. BlazeX offers higher material removal rates in a wide range of grinding processes in stainless steel and harder-to-grind materials.

- New Norton for Aluminum Thin Wheels for the right angle cutting and grinding of aluminum and other non-ferrous soft metals. High quality, extra-friable and self-sharpening aluminum oxide grain and specialized bond technology results in the best cutting and grinding wheel market performance in its class.

Compact Robotic Welding System Facilitates Welding for Several Processes

Re-engineered Cobot Greatly Expands Automation Opportunities

Pemamek LLC (Mason, OH), a North American subsidiary of Finland-based Pemamek Oy Ltd., will be exhibiting its PEMA Skytrack in Booth B35039. The Skytrack is a compact robotic welding system to facilitate welding of transmission housing, gearboxes, drive units, hydraulic units and more. Attendees will have the opportunity to view the Skytrack and the PEMA WeldControl 300 Offline software, a powerful control that enables the programming, simulation, and verification of workpieces at the work cell instead of at a CAD/CAM workstation. The Skytrack also features the intelligent PEMA Skyhook Positioner with integrated robot track. Movement on every axis is servo-motor driven and fully integrated with the controller for synchronous movement of the robot and positioner. This configuration helps maintain the proper axis or plane on the weld element so that it can be rotated and turned synchronously in the correct PA position for the best possible weld joint penetration and deposition. This gives manufacturers the ability to produce high quality parts while preventing worker fatigue and injury.

While Pemamek’s FABTECH booth will highlight all significant products and software solutions for automated welding applications, special attention will be given to its dedicated expertise and technology for the offshore wind manufacturing sector.

Pemamek Ltd., founded in 1970, is a global welding and production automation leader. With extensive 50-year experience in welding and production automation, Pemamek is dedicated to helping heavy fabrication industries, such as shipbuilding, wind energy, and the power generation industry, to raise their levels of productivity.

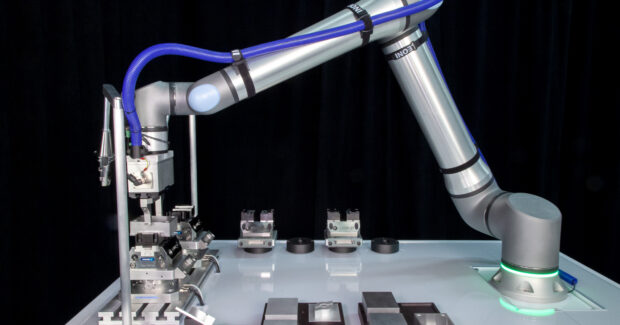

Re-engineered Cobot Greatly Expands Automation Opportunities

With its 1,750 mm (68.9”) reach and 20 kg payload (44.1 lbs.), the new UR20 cobot from Universal Robots (Novi, MI) greatly expands automation opportunities such as the ability to reach further into machines, tend several machines in the same cycle, and handle 25% heavier parts. Despite being UR’s heaviest robot, the UR20 is the lightest cobot in its class, weighing only 64 kg (141.1 lbs.).

The new UR20 cobot, which will start shipping this summer, has been re-engineered from the ground up, focused on freeing up more manpower within a wide range of human-scale automation tasks.

At Universal Robots’ Booth B17063, attendees will experience first-hand what that looks like as the UR20 loads and unloads heavy workpieces into a machine fixture requiring a long reach. Universal Robots has completely re-engineered the cobot’s field-serviceable joints that deliver 30% more speed and torque within a closed capsule. Even with the increase in reach and torque, the cobot pioneer has managed to retain the cobot’s 50 microns repeatability, while still using standard single-phase power.

Mini Beveller is a Great Addition to Your Fabrication Toolbox

SP AIR’s SP-7252F Air Mini Beveller from VESSEL TOOLS USA (Torrance, CA) is a pneumatic beveling machine ideal for fabrication, marine and automotive along with industrial applications and when beveling the edges of metal gauge panels and metal tables (in motorcycle fabrication). The product features a three-blade cutting head with changeable blades, depth flange scale for setting cutting depth, palm size tool cuts radius chamfers and straight chamfers, and cuts circles with a minimum of 0.27” and material thickness of 0.1”, free speed 23,000 rpm. VESSEL TOOLS will be at Booth B37069.

This small handheld beveling tool works great in tight areas. It is ideal for deburring welds, beveling edges or for counter sinking for screw heads. For aluminum, this tool works well because it moves the debris out of the front of the tool, cooling the metal as you work.

The system works using a three-blade system; the cutting blade is in the no. 1 position. You can rotate the blade two more times when the no. 1 blade dulls down, turn the no. 2 blade into cutting position and then the no. 3 side so you will always have a sharp blade available. New three-blade sets are also available to replace all the blades when they are dull. SP Air is made in Japan and has been making innovative, quality pneumatic tools since 1973.

Evolution of Abrasives Increases Uptime and Overcomes Labor Constraints

Weiler Abrasives (Cresco, PA), a leading provider of abrasives, power brushes and maintenance products for surface conditioning, will display surface conditioning solutions to help users increase uptime and improve productivity, as well as overcome labor constraints, health and safety issues and increasing expectations. Weiler Abrasives will be at Booth B33027. Visitors can learn more about solutions for a variety of industries, including shipbuilding and general fabrication, and a brand-new line of Tiger 2.0 zirconia alumina and aluminum oxide cutting, grinding and combo wheels. In addition to offering fast cutting speed, Tiger 2.0 wheels last up to 40% longer to increase efficiency in operations’ cutting and grinding applications. The wheels feature an award-winning blotter design that includes an industry-first, patent-pending Optimum Use Line. The line is a visual indicator that helps the operator use the wheel to its full life. This innovation reduces changeovers, allowing for greater productivity while also reducing waste and abrasive spend. Tiger 2.0 grinding wheels also feature anti-chipping technology, an advanced bond formulation that reduces uneven edge wear and chipping to improve safety and the user experience and extend wheel life.

Weiler Abrasives’ specialists will also be scheduling consultations at the booth to help visitors understand their abrasive spend, along with ways to increase productivity and eliminate grinding and finishing bottlenecks. These can’t-miss consultations will include a thorough discussion of the steps needed to overcome challenges in the surface conditioning process, whether they are related to labor, safety or increased customer demand. Specialists can also offer recommendations for better ways to grind and finish stainless steel, Inconel, aluminum, and other hard-to-work-with materials — and how to choose the right abrasive for specific applications.

To learn more about the featured products or to schedule an in-booth consultation during the show or a phone consultation prior to the show, visit the FABTECH landing page.

Flexible Human-Collaborative Workcell

Designed for human-collaborative (HC) interaction, the highly flexible ArcWorld HC is a complete robotic welding solution for the fabrication of small- to medium-size parts. Ideal for replacing or supplementing manual weld processes, such as pre-assembly before welding in larger robotic workcells, this pre-engineered mobile cart system is well-suited for high-mix, low-volume production.

Joining Yaskawa Motoman’s (Dayton, OH) proven line of ArcWorld welding workcells, this portable job shop with three-sided access comes complete with a 1,200 mm-x-2,400 mm perforated fixture table, a single HC10DTP robot, retractable arc curtain, built-in exhaust hood, a compatible Miller®, Lincoln Electric, SKS, OTC or Fronius power supply, a 14-gauge metal tool board, tool balancer and debris tray. Yaskawa Motoman will be in Booth B20051. A 120 VAC 20-amp electrical extension outlet and 120 psi air connection are provided for common welding tools. Overhead LED lighting provides interior illumination, and solid wheels and leveling feet enable quick and easy installation or relocation. Wire spool and shield gas bottle holders are optional.

Featuring Power and Force Limiting technology for safe operation and hand-guided teaching for easy programming without a pendant, the HC10DTP robot welds parts with efficiency and consistent high quality. Offering a 1,379 mm maximum working range and a 10 kg payload capacity, the HC10DTP can process parts up to 500 H-x-2,000 W-x-800 D mm. Its IP67 rating enables welding without additional coverings or equipment. Fast air cut speeds (500 mm/s) are easily achieved with arc curtain closed, or they can be maintained at collaborative speed (200 mm/s) when the curtain is open. Risk assessment provided for assured, safe design.

The HC10DTP robot for welding is controlled by the high-performance YRC1000 controller that utilizes a lightweight, standard teach pendant with intuitive programming. Processes from the power supply are accessed by Yaskawa’s easy-to-use digital Universal Weldcom Interface, giving full control of welding parameters and settings from the robot programming pendant.

New Audio AI and Solutions for Welding Quality Control

Xiris Automation (Burlington, Ontario), a leading provider of camera-based solutions for quality control in the metal fabrication industry, will be at Booth B15073. Visitors can witness the unveiling of Xiris’ newest and innovative products, including the groundbreaking artificial intelligence (AI) audio tool for welding.

One of the highlights of Xiris Automation’s showcase at FABTECH is the release of its AI tool designed to process welding audio signals. With the Audio AI tool, fabricators can now establish an acceptable range of audio signals for welding processes and receive real-time alarms for anomalies such as burn-through and wire feed skips that could indicate welding defects.

Developed as a result of extensive product development efforts, the Audio AI tool meets fabricators’ demands for remote monitoring of welding processes and the ability to detect process discontinuities. Leveraging the audio signal generated by Xiris’ WeldMic™, the Audio AI tool can be easily trained in production, using a self-learning algorithm from an audio sample of the user’s welding process.

Included with Xiris’ WeldStudio™ 3 Pro software, the Audio AI tool provides a user-friendly interface for camera controls, graphical overlays, video recording and playback, as well as image and audio processing.

“We are excited to present our latest innovation, the AI Audio tool, at FABTECH 2023,” said Cameron Serles, CEO at Xiris Automation. “This cutting-edge solution empowers fabricators to monitor welding processes with greater precision and efficiency, ensuring the highest level of quality control.”

Subscribe to learn the latest in manufacturing.