ANCA’s FX5 Gets a Power-boost with a new 12 kW Grinding Spindle

ANCA is celebrating the versatile FX machine platform as the 1,000th FX5 rolls out the door.

Posted: August 10, 2023

ANCA has upgraded the FX5 Linear 2-wheel pack machine with a new grinding spindle rated at 12 kW peak power as well as releasing a further high-powered spindle option of 19 kW.

ANCA has upgraded the FX5 Linear 2-wheel pack machine with a new grinding spindle rated at 12 kW peak power as well as releasing a further high-powered spindle option of 19 kW.

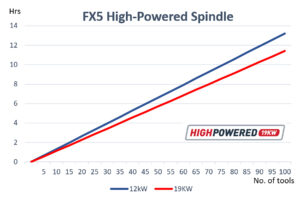

CNC tool grinders strive to achieve the shortest possible cycle times – to keep the cost per tool produced at a minimum. Machine performance and grinding cycle time are linked to the power capabilities of the grinding spindle.

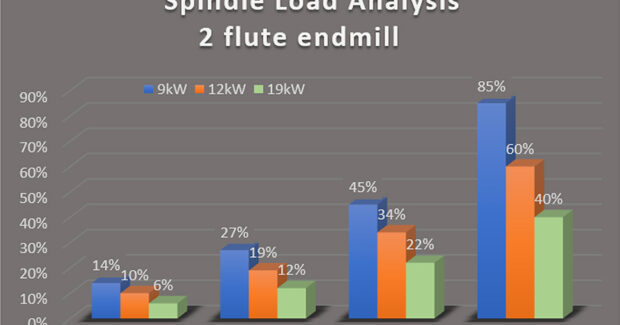

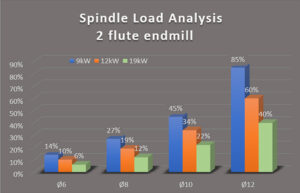

To maximize material removal rate, a commonly accepted industry practice is limiting the spindle load to between 30% and 40% for fluting operations. If the spindle load is likely to exceed 40%, tool manufacturers tend to allow for a second fluting pass as this contributes to longer wheel life and less wheel load. Auto white-sticking becomes an important option as batch sizes increase.

ANCA has conducted a spindle load analysis of fluting operations, identifying how many passes are recommended in relation to spindle load. The analysis compares two flute endmills ground with either 6, 8, 10 or 12 mm diameters. The new FX5 which has now been upgraded from 9.5 kW to a 12 kW spindle can comfortably grind tools up to 10 mm diameter in a single pass. A 12 mm tool required a second grinding pass to keep the spindle load at 40%, rather than increasing to 60%.

This is where the new high-powered 19 kW spindle option makes all the difference. The 12 mm endmill was ground at a 40% spindle load in one pass, with an overall time saving of one minute and four seconds – opposed to two passes at 12 kW.

Match “One Pass Productivity” to tool diameter

The FX5, with the new 12 kW spindle delivers increased productivity up to a diameter of 10 mm. At 19 kW, the new high-powered spindle option can enhance productivity further for tools up to 12 mm and above. The high-powered spindle option on FX5 matches the grinding spindle fitted to the FX7 machine with 6-wheel packs, suited for a more industrial environment.

The FX5, with the new 12 kW spindle delivers increased productivity up to a diameter of 10 mm. At 19 kW, the new high-powered spindle option can enhance productivity further for tools up to 12 mm and above. The high-powered spindle option on FX5 matches the grinding spindle fitted to the FX7 machine with 6-wheel packs, suited for a more industrial environment.

The new FX5 upgrade option features a striking high-powered decal indicating it has been fitted with the more powerful 19 kW spindle.

For complex cutting tools, there can be of course further factors which influence actual grind cycles besides the tool geometry. These include the quality of the grinding wheel used and the supply of an adequate amount of cooling liquid at stable temperature, to avoid thermal damage of the workpiece. As batch sizes increase auto white-sticking helps to achieve maximum output by frequently refreshing the wheel.

Customers will benefit from the increased spindle power provided by the new 12 kW standard spindle on FX5 and now have the option to purchase their new ANCA FX5 with a high-powered spindle, adding more flexibility in the tool room. Most importantly the high-powered spindle reduces the production cost and increases net output across a wider range of tools.

The use of “One Pass Productivity” for tools with 12 mm diameter translates into an increased output of 15.8% – with 70 tools produced in an eight-hour shift compared to 60 tools with the new standard 12 kW spindle.

The FX5 Linear continues to deliver customer satisfaction with 1000 machines sold

Contributing an impressive 1,000 machines to the 1,600 machines produced across the entire FX platform, the FX5 is an easy choice for customers, from light manufacturing, to regrinding and full production. Across a range of industries, the upgraded FX5 is the most versatile 2-wheel pack machine for a variety of applications.

ANCA is a market leading manufacturer of CNC grinding machines. It was founded in 1974 in Melbourne, Australia where the company still has its global headquarters. ANCA has offices in the UK, Germany, China, Thailand, India, Japan, Brazil and the USA as well as a comprehensive network of representatives and agents worldwide.

ANCA CNC grinders are used for manufacturing precision cutting tools and components across a diverse range of competitive industries including cutting tool manufacture, automotive, aerospace, electronics and medical.

Subscribe to learn the latest in manufacturing.