Automated and Robotic Welding Solutions Solve Your Greatest Problems

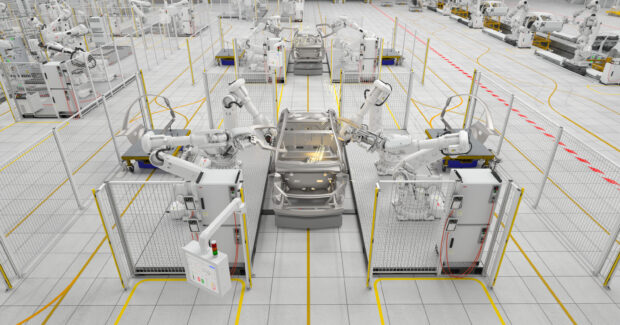

Robotic cells and automated material handling systems provide compelling solutions to address your shop’s labor shortages.

Posted: August 28, 2023

Robotic and automated processes are forever changing the way fabrication shops function. If you are just getting started or researching the next levels, robotics and automation suppliers are close at hand, ready to meet your needs today and in the future.

Company Expands Large Robot Family with Four Energy Saving Models

ABB Robotics & Discrete Automation (Auburn Hills, MI) has expanded its large robot range with four new models and 22 variants, offering more choice, increased coverage and greater performance. The next generation models include the IRB 6710, IRB 6720, IRB 6730 and IRB 6740, suitable for payloads ranging from 150 kg-to-310 kg, with a reach from 2.5 m-to-3.2 m, offering customers greater choice and significant performance and energy efficiency improvements.

“ABB’s four new robots offer 22 variants and energy savings of up to 20%, responding to our customer’s needs; offering more choice and greater flexibility for more sustainable production,” said Marc Segura, President of ABB’s Robotics Division. “These new robots will help our customers build resilience across a range of industries including automotive, general manufacturing, foundry, food and beverage and logistics.”

The improved energy efficiency is driven by ABB’s OmniCoreTM controller, and a lighter robot design, leading to energy savings of up to 20%. OmniCore also offers high motion control accuracy. Featuring ABB’s TrueMove and QuickMove motion control technology, the robots can achieve class-leading repeatability with a minimum of 0.03 mm deviation. These capabilities make the new series of robots ideal for complex tasks such as spot welding, laser welding, screwdriving and riveting, allowing automotive manufacturers to achieve high quality assembly.

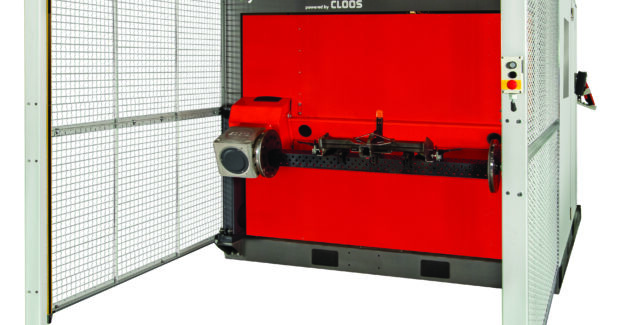

Customized “Ready to Weld” Solution for Automated Robotic Welding

Bystronic Inc.’s (Hoffman Estates, IL) Robotic Welding Cell powered by Cloose RCRobotic Welding, Inc. offers three specific robotic welding cell models each having a specific scope of application based on the size and weight of the parts to be welded, and each with a two-station work piece positioner.

The Micro Cell features an overall clamping length of 55” and a nominal load capacity of 280 lbs. per side for the manual rotating work piece positioner, and a 400A welding power supply.

The Compact Cell features an overall clamping length of 61” and a nominal load capacity of 562 lbs. per side for the automatic rotating work piece positioner, and a 450A welding power supply.

The Compact System features an overall clamping length of 138” and a nominal load capacity of 2,248 lbs. per side for the automatic rotating work piece positioner, and a 450A welding power supply. All welding cell models maintain an integrated safety system including nozzle search and anti-collision sensors, interlocked doors, safety enclosures with operator window, and when required, safety fencing and light curtain barriers.

Robot Designed to Handle Heavy Products

FANUC America (Rochester Hills, MI), the leading supplier of CNCs, robotics, and ROBOMACHINEs, offers the M-1000iA robot capable of handling very heavy products including automotive components, construction materials and battery packs for electric vehicles.

The M-1000iA’s serial-link construction gives the robot a wider range of motion in every direction. It can extend its arm upright or rotate it backwards, which is not possible for typical heavy-payload robots with a parallel-link mechanism. With a 1,000 kg payload, a 3,253 mm horizontal reach, and a 4,297 mm vertical reach the M-1000iA is ready to go to work for manufacturers looking to increase output and maximize their production line’s efficiency.

Powered by the FANUC R-30iB Plus Controller, the M-1000iA offers the same intelligence and reliability that FANUC robots are known for, including integrated iRVision®, force sensing and Zero Down Time.

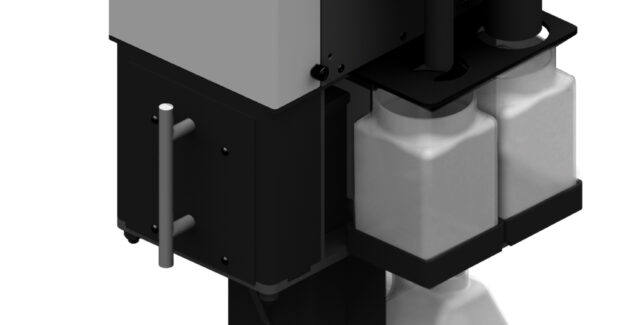

Tip Exchange System Improves OEE of Robotic MIG Welding Cells

Nasarc Technologies, Inc. (Waterloo, Ontario, Canada), a leading provider of advanced robotic welding solutions recently released the innovative Tip Exchange System (TES), comprising of the AUTOTIP, AUTOCLEAN and REVOLUTION360. TES is designed to improve the overall effectiveness of robotic MIG welding cells by automating the routine task of removing and replacing the contact tip from the torch, providing next-generation torch maintenance center technology and a state-of-the-art robotic MIG welding torch — all together increasing productivity while minimizing downtime and costs.

TES is comprised of three products. The AUTOTIP is an automatic tip changer that automates the task of manually replacing a MIG welding contact tip. It removes and replaces a spent tip with a new one, reducing tip changing time to as low as 30 seconds. An onboard tip cartridge allows for 175 tip changes without operator intervention.

The AUTOCLEAN is a robotic torch maintenance center designed to improve overall equipment effectiveness in robotic MIG welding cells. It is engineered to increase productivity and quality while minimizing downtime and costs. It features an automated nozzle reamer, nozzle removal and replacement, tip and diffuser cleaning, wire cutter, anti-spatter sprayer, and nozzle gas flow sensor.

The REVOLUTION360 is an infinite rotation robotic MIG torch that provides a revolution in robotic MIG welding. Engineered for industrial applications, it is extremely durable and thermally stable to provide a high-quality weld with every arc. It features a high conductivity rotary power connector, innovative gooseneck connection, robust cable design, stainless steel gooseneck, and high-quality consumables.

Partners Expand Automated Pipe Welding Solution

Novarc Technologies Inc. (North Vancouver, British Columbia, Canada), a full-stack robotics company specializing in the design and commercialization of collaborative robots (cobots) and AI-based machine vision solutions for autonomous welding, has partnered with Lincoln Electric, the leading global manufacturer of advanced arc welding solutions and automated joining, assembly and cutting systems, to expand Novarc’s automated cobot pipe welding solutions.

As part of the partnership, Novarc will integrate Lincoln Electric’s welding technologies, including Lincoln’s patented Surface Tension Transfer® root pass technology and HyperFill® twin wire MIG welding solutions into Novarc’s automated cobot pipe welding solution. Additionally, Lincoln Electric will promote Novarc’s Spool Welding Robot (SWR) for automated cobot process pipe welding.

“We are excited to collaborate with Lincoln Electric on the development and marketing of our Spool Welding Robot and other new products in robotics and AI,” said Soroush Karimzadeh, CEO of Novarc Technologies. Lincoln Electric is an established brand renowned as a global manufacturer of arc welding solutions, and this new partnership is a natural evolution of our relationship to provide our collective clients with the leading automated cobot pipe welding technology solutions. Our SWR solution has generated over a 400% productivity increase for clients in industries such as contract manufacturing and shipbuilding and we expect our collaboration with Lincoln Electric to expand upon leading joint solutions such as SWR+HyperFill will drive added value for customers.”

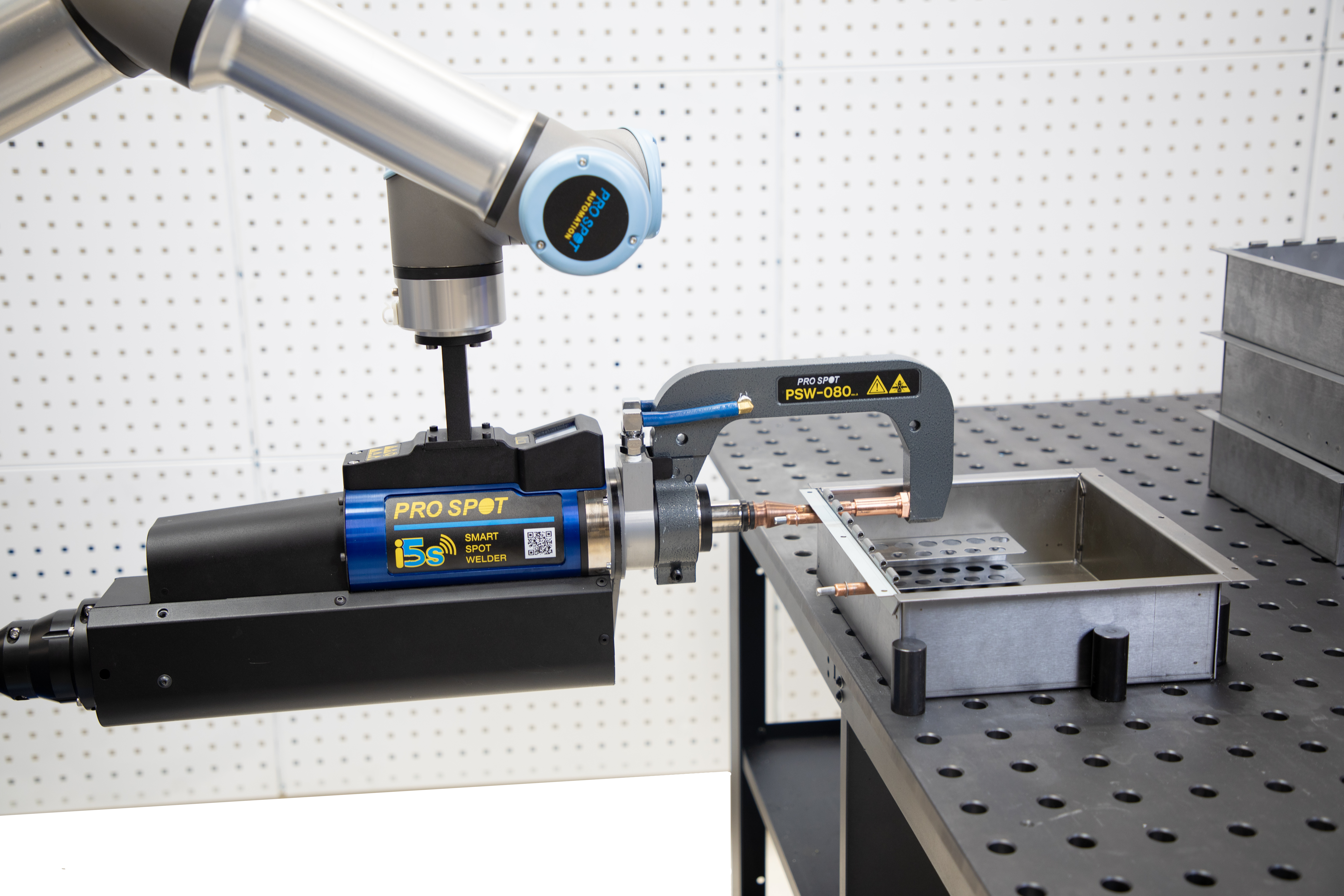

World’s First Cobot Spot Welder Partners with Cobot Platform Leader

Pro Spot International (Carlsbad, CA), the designer and manufacturer of the world’s first cobot spot welder, was part of Universal Robots’ (Novi, MI and Odense, Denmark) booth at Automate earlier this year. While other welding technologies such as MIG welding have become popular choices for collaborative robots, spot welding has up until now been prohibitive for cobots due to the weight of the weld gun and the complexity of the welds. With the i5s resistance spot welder, Pro Spot has developed a lightweight solution, delivering two-to-three times more manufacturing capacity than manual spot welding.

“We married our most sophisticated spot welder with Universal Robots’ safe, unrivaled technology,” said Ron Olsson, president and founder of Pro Spot International. “The combined platform is a powerhouse of productivity and throughput greatly benefiting any manufacturer who joins sheet metal through spot welding.”

![]()

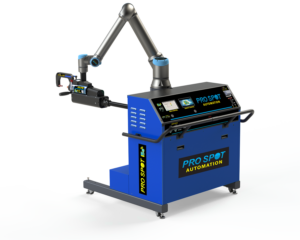

![]() Pro Spot International is eagerly looking to incorporate the new UR20 cobot into its applications for added reach and payload capabilities. The award-winning UR20 with 20 kg payload and 1750 mm reach starts shipping later this summer and will be showcased at the UR booth in a machine tending application, loading and unloading heavy workpieces into a machine fixture.

Pro Spot International is eagerly looking to incorporate the new UR20 cobot into its applications for added reach and payload capabilities. The award-winning UR20 with 20 kg payload and 1750 mm reach starts shipping later this summer and will be showcased at the UR booth in a machine tending application, loading and unloading heavy workpieces into a machine fixture.

Subscribe to learn the latest in manufacturing.