Three Benefits of Using a Shop Floor Coordinate Measuring Machine

Software and measuring methodology is growing to capture more detail, organize data, and move faster than ever.

Posted: August 18, 2023

Measurement is necessary for the production process across many industries. It ensures that parts fit together, helps with quality control and compliance with regulations, and more. However, measuring parts can be a tedious process that requires outsourcing labor and specified measuring sites. Although it is necessary to measure parts, the necessity doesn’t take away from the fact that it can be a laborious and inefficient process.

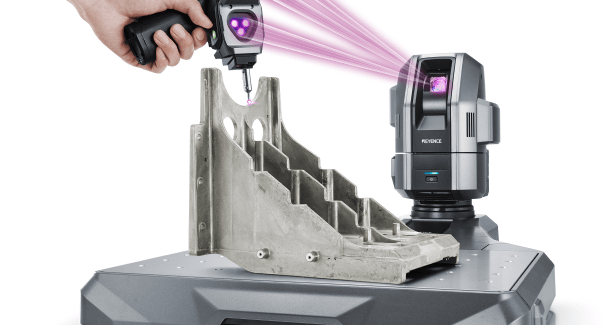

Adding a shop floor coordinate measuring machine (CMM) can solve this problem. A CMM measures geometric data by taking coordinate points on an object. Frequently used in aerospace, automotive and medical industries, CMMs increase efficiency, allow for flexibility and ensure precision. Keep reading to learn more about the three benefits of using a shop floor coordinate measuring machine.

1.CMMs Improve Efficiency

Incorporating shop floor coordinate measuring machines uses production time, costs and labor more efficiently. Without using a shop floor CMM, the measuring process involves stopping production, disassembling parts, transporting them to the designated measurement site, reassembling and repeating. Adding a shop floor CMM wipes out all these extra processes and increases efficiency.

Shop floor CMMs use time and budget more efficiently by doing the following:

- Eliminating cost and time spent stopping production for measurements.

- Eliminating cost and time spent transporting parts to and from the metrology floor/site.

- Eliminating time spent taking apart a component and putting it back together for measurement.

- Eliminating time and cost of outsourcing measurement sites and metrologists.

Shop floor CMMs allow you to integrate metrology into the production time for both processes simultaneously. The time and money used for outsourcing metrology can be reallocated to other areas of the shop, like making bigger production batches or buying new manufacturing equipment to help increase efficiency. In industries with strict metrology requirements, like the medical device industry, improved measurement practices could result in better quality products and better compliance.

The amount of time spent measuring can widely vary, from days to a few minutes. For example, handheld and portable CMM devices with intelligent augmented technology are quick to use and easy to understand, allowing anyone to produce fast and accurate results.

- CMMs Offer Flexibility

Shop floor coordinate measurement machines offer measurement flexibility because they can tackle a large range of parts. There are different types of CMMs, and each type provides specialized flexibility. Here are a few common types:

- Gantry CMMs on wheels allow easy movement around the shop floor across production stations.

- Handheld CMMs, like arm-style and vision based CMMs, allow easy movement around the shop floor and flexibility of angles, heights, lengths and widths that they can measure.

Depending on the needs and requirements of your shop floor CMM, certain features can help save time and money. As an example, some CMMs are made with optimal user experience (UX) in mind so that there is operator flexibility.

Environment flexibility

Shop floors have many different environmental factors — ambient vibration, changing temperatures, debris, dust, oil and water — and many shop floor CMMs combat that with specialized technology. Here’s an example:

- Handheld CMMs like arm-style or vision based CMMs may have temperature control settings that can account for thermal expansion/compression within their software. This provides a standardized measurement no matter the room temperature. They’re also designed to withstand these production environments so measurement can be done right on the shop floor to optimize efficiency and streamline production.

- CMMs Provide Precision

Adding shop floor CMMs is a beneficial way to add more precision to your measurement process. Here are just a few reasons why:

- Portable CMMs make it easy to collect measurements at your production site that easily integrate into your databases or SPC software.

- Advanced shop floor CMMs have technology like augmented reality that allows users to visualize the measurements exactly on their part. This allows for anyone, even a metrology novice, to easily and accurately inspect parts.

Adding a CMM onto Your Shop Floor

Introducing shop floor CMMs will benefit your production process, turning it into a more efficient, flexible and precise system. By no longer needing to pause production entirely and go to another site to measure a part, shop floor CMMs optimize your time and budget. Resources can be reallocated to enhance product quality, keep up with industry changes and produce bigger batches.

When adding a CMM to your shop floor, making an educated choice that will benefit your manufacturing process is necessary. When evaluating a CMM, compare its features to your shop floor qualities. Some considerations for your coordinate measuring machine options:

- Type of parts — curved or angled corners

- Part sizes

- Shop floor environmental factors — temperature, vibration and debris

- Industry regulations

- Ability for repeatability

Flexibility and precision of shop floor CMMs will only improve as technology advances. The software and measuring methodology is growing to capture more detail, organize data, and move faster than ever. As such, consider using a shop floor CMM to enhance your production.

Subscribe to learn the latest in manufacturing.