Lock into the Potential of High-precision Imaging

Versatile and fast video inspection systems speed up the process of peeking into your processes, while maintaining maximum efficiency.

Posted: September 27, 2023

Your metalworking shop won’t miss a thing with features in video inspection systems such as distortion-free imaging, digital zoom, zero copy image transfer and super high-resolution images.

Major Advancements in Imaging Tech

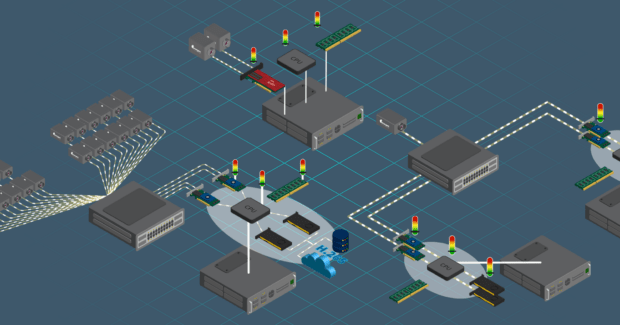

Emergent Vision Technologies (Port Coquitlam, BC, Canada), a pioneer in high-speed GigE Vision cameras and zero-data-loss vision technologies, has released a new video presentation that details major advancements in high-speed imaging technologies, including machine vision cameras, network interface cards and other processing technologies, and software.

Differences exist between communications protocols that, when understood, can unlock the next level of performance in high-speed imaging. This presentation explains the differences between a GigE Vision Stream Protocol that leverages the user datagram protocol approach, as opposed to remote direct memory access, for example. The presentation also dives into processing technologies and how they unlock new capabilities for high-speed imaging, such as zero copy image transfer and GPUDirect.

Videoscope Makes Turbine Gearbox Inspections Faster

Wind turbine gearbox inspections take place in cramped quarters, so inspection tools must be compact and effective. Designed specifically for these challenges, the Evident (Waltham, MA) IPLEX™ G Lite-W videoscope combines portability with powerful imaging features packed into a small, ergonomic form factor.

The IPLEX G Lite-W videoscope’s sealed tip keeps oil out while channels on the oil-clearing tip adaptor use capillary action to draw oil away from the lens, helping keep images clear. This videoscope is designed to meet IP65 standards and built to pass U.S. Department of Defense testing. Weighing only 1.16 kg (2.56 lbs.) it is easy to carry.

The videoscope’s optics balance the need to see areas of the wind turbine gearbox up close, such as bearings and gear teeth, spot defects in large spaces and be small enough to fit into the spaces between turbine bearings to look for damage.

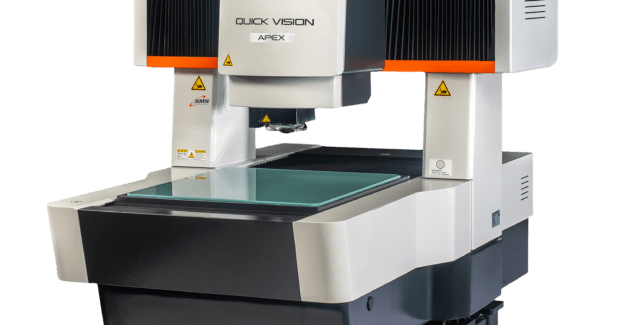

Advanced Non-contact Measuring System Delivers More

Mitutoyo America Corp.’s (Aurora, IL) Quick Vision Pro Series machines, the latest generation of Mitutoyo Vision Measurement Systems, are packed with high-performance technologies that greatly improve 3D non-contact measurement and productivity. This highly advanced system delivers even more speed, efficiency and versatility.

The QV Pro Series features newly developed StrobeSnap vision measuring function that speeds up run time by approximately 35-to-45% regardless of measurement position or continuity while achieving higher throughput and high-precision measurements. Auto focus on the QV Pro Series is about 39% faster than previous models, which were already fastest in their class, without loss of accuracy.

An optional Stream function realizes very high throughput using non-stop measurements that synchronizes the main XY unit drive and strobe lighting. It takes images intermittently without stopping the stage and performs batch measurements at the same time. The optional Tracking Auto Focus utilizes a laser tracker that keeps the part in focus so the program does not have to stop for auto focus and stops potential errors from occurring if the part is out of focus.

Subscribe to learn the latest in manufacturing.