Manufacturer Increases Solid Carbide Mills Developed for Machining Aluminum

Walter USA brings an exciting expansion to its solid carbide milling offering with new tools for machining aluminum alloys.

Posted: September 27, 2023

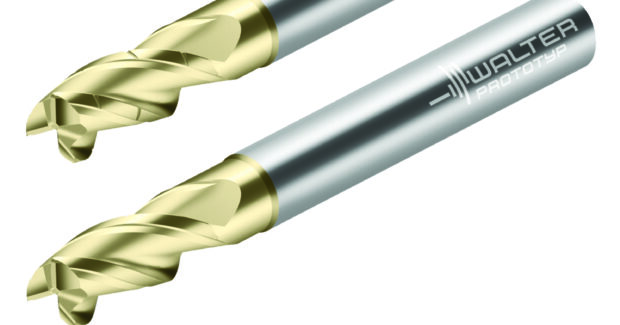

Walter takes the lead in solid carbide milling with the introduction of more than 3,000 new cutting tools in inch sizes. The expansion includes the MA267/MA263 Advance milling tools with straight-forward proven geometries for a cost-effective and reliable milling process at an extremely high metal removal rate and the MA268 for high-velocity rough machining.

Available in diameters from 1/8″ to 1″, the MA267/MA263 Advance tools are excellent for machining all other ISO N materials, such as copper, brass, bronze and magnesium-based alloys, in addition to aluminum. With a cylindrical shank, these tools are available with or without chip-splitters.

The WJ30UU grade for the MA267/MA263 tools is uncoated, and the WJ30CD grade features a wear-resistant zirconium nitride (ZrN) coating to achieve maximum productivity and tool life. The MA263 with chip breaker geometry reduces cutting pressure and vibration at high feed rates. Both versions offer end geometry that is designed for aggressive ramping.

Benefits include imparting consistently fine surface finishes throughout the entire tool life, polish grinds to generate superior surface finishes on both walls and floors, and a polished flute face that optimizes chip evacuation.

Walter also developed the MA268 to machine all ISO N materials at the highest level. The solid carbide milling cutter has a 39° helix and is available from 1/4″ to 1″ in diameter. The tool has a cylindrical shank and is available with a standard or reduced neck. The MA268 is also offered in the uncoated WJ30UU grade and the WJ30CD grade with the reliable ZrN coating. The cutter’s unique geometry reduces cutting pressures and vibration at high feed rates. The highly polished OD and flute face prevents chip build-up. Knuckles, or the serrated cutting edges, shorten the chip length to aid chip evacuation and reduce tool pressure.

The Walter lineup of products consists of three categories of tools. Supreme tools indicate the highest level of technology and performance available. Advance tools indicate products efficiently balanced between price and performance and Perform tools are products that provide an economical solution with focused importance on price.

Walter, a global leader in the metalworking industry for over 100 years, offers a wide range of precision tools for milling, turning, drilling and threading applications. The company helps customers in the aviation and aerospace industries, automotive, energy, and general metalworking industry improve process reliability and increase productivity. As an innovative partner capable of creating digital process solutions for optimal efficiency, Walter is pioneering Industry 4.0 throughout the machining industry. With Regional Headquarters in Greer, SC, Walter markets its competence brands Walter, Walter Titex, Walter Prototyp and Walter Multiply through a network of channel partners and field engineers across the USA, Canada, Mexico and Brazil.

Subscribe to learn the latest in manufacturing.