Innovative Sawing Systems Increase Success in a Range of Applications

Fewer blade changes, one stop approaches, and automatic feeds and saws maximize productivity with little operator involvement.

Posted: November 7, 2023

Advances in blade tooth geometry and automated sawing systems provide longer blade life, highly precise cuts, and storage solutions in tight spaces.

Automatic Miter Circular: All-rounder for Cutting Tubes, Profiles and More

Behringer Saws Inc.’s (Morgantown, PA) new Eisele PSU-450M is an automatic feeding and automatic mitering circular cold saw, with capacities of 5.9” diameter round and 5.5” square. This upcutting style machine is designed for the precision sawing of pipes, tubes and solids.

With its servo-driven axis, it assures accurate and repeatable length positioning and miter angle adjustment. The ability to miter to 30° in both directions offers a great deal of flexibility and functionality. It’s upcutting design assures the best possible cut quality, as well as contributing to exceptional blade life and low cost/cut.

With a user friendly and intuitive operating control system, changing from job to job is effortless. The standard sawing range of 6-to- 48 rpm (with optional 12-to-96 rpm), allows for the ability to saw a broad range of materials and configurations. The rigid design and cast-iron construction assure the PSU-450M stands up to the most demanding fabrication applications. If speed, accuracy, and flexibility are what you are seeking in your next fabrication saw, look no further than the PSU-450M.

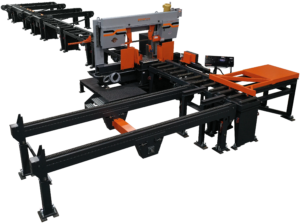

Cutting Solutions for Every Application

Vertical tilt-frame band saws from Cosen Saws (Charlotte, NC) have been delivering exceptional results to manufacturers for decades. The three models — manual, semi-automatic and fully automatic — provide precision, efficiency and convenience. They accommodate a wide range of cutting requirements, from small-scale operations to large-scale manufacturing facilities.

The entry level Cosen Saws V-1822 is ideal for workshops and small-scale operations. With its heavy-duty construction and compact footprint, it delivers precise and consistent cuts, providing customers with a cost effective and dependable cutting solution.

The intermediate level Cosen Saws V-2026NC & V-2230NC are versatile band saws that are a great choice for medium-scale industrial applications. Operators can easily load the material, set the cutting parameters, and let the saw perform the cutting process. These saws offer precision, efficiency in operation, lower cost per cut, and durability.

The pinnacle of cutting performance, the Cosen AV-2026NC, represents a best-in-class solution for large-scale industrial operations. It is designed to handle high-volume cutting with precision. The fully automated saw integrates advanced features, including material feeding, cutting angle adjustment, and length positioning. The saw maximizes productivity while minimizing operator intervention.

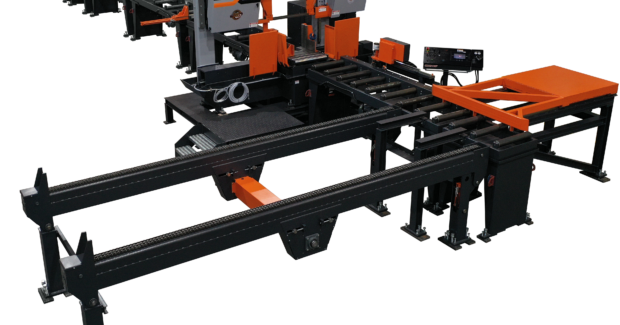

One-Stop Sawing System Approach

Metal distributors and fabricators have something in common — moving metal. Material must keep moving and doing so efficiently can mean the difference between making money and losing money. A common complaint from many metal distributors and manufacturers is “throughput”: moving material internally, through one or more processes and out the door. A thorough evaluation of the material flow throughout the entire process can offer insights that maximize time and increase throughput and profits.

Because HE&M Saw (Pryor, OK) is based in engineering our ability to design systems that integrate more seamlessly into a customer’s location, process, and budget can result in an entire sawing system: saws and the equipment to handle the material before and after the cut, said Paul Beha, HE&M Saws products manager. This provides an efficient outcome because design, manufacturing, installation and service after the sale are all available from HE&M Saw’s “one-stop-shop.”

The company’s products have historically been based on this engineered approach. This mindset was the foundation first cemented by company founder, Gerald Harris, and is being continued by both the second and third generations of the Harris family. That philosophy holds true for the material handling products that the company designs and builds. Consideration of material handling components should be integral with any sawing process.

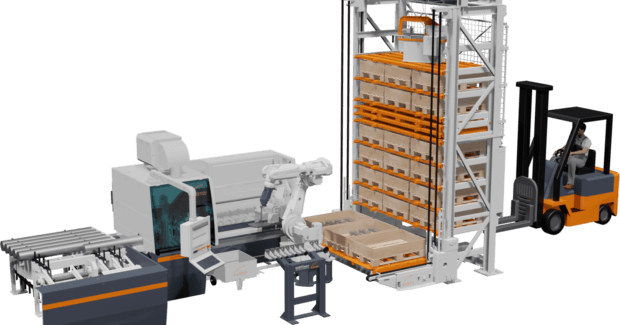

Smart Flow of Materials Enables Unstaffed Operations in Tight Spaces

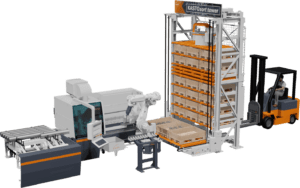

Automating sawing and storage processes with a shop that is already full? For metalworking companies, this has been a pipe dream. KASTO Inc. (Export, PA) wanted to solve the problem and the solution is a space-saving, fully automated system for processing, including sorting, which works 24/7.

The new KASTOsort tower appeals to metalworking companies and service centers that already use a high-performance saw such as the KASTOvariospeed or KASTOtec with or without KASTOsort robots. For an efficient process, the parts can be sorted by order after sawing and placed in appropriate boxes.

The fully automatic production circular saw KASTOvariospeed is ideally suited for high performance requirements with small-to-medium order sizes, independent of the material quality, shape and dimensions. The KASTOtec production band saw was developed for the optimal use of the bi-metal, coated bi-metal, carbide and coated carbide tool technologies.

The KASTOsort’s space requirement is a little more than 120 square feet for a KASTOecostore storage system in medium format. To realize the idea, the developers combined proven KASTO technologies into a highly productive concept, which in the current configuration consists of a chain magazine at the infeed side, a KASTOvariospeed circular saw, a KASTOsort robot and a KASTOecostore storage system. Other KASTO saws, or even third party manufacturing machines can also be connected. The tower storage system offers optimal use of vertical space, high storage density and flexibility in material intake with short access times.

The KASTOsort tower’s ProControl control system ensures fast, error-free work processes and smooth interaction of the components. The KASTOlogic mobile app can also be used to manage storage. The user can record the material seamlessly and see where it is in the production process at any time.

High Productivity Bi-metal Band Saw Blades for Structural Cutting

The L.S. Starrett Co. (Athol, MA) now offers TENNAX™-PRO Band Saw Blades, which are designed to cut challenging tubes, pipes, profiles and structural shapes in both single pieces and bundles. Providing lower noise and vibration as well as improved cutting performance, these blades outlast and outperform competitive blades, making up to 25% more cuts per blade.

The TENNAX-PRO blades feature high-speed M-42 steel teeth with a new special tooth geometry/profile that optimizes the tip profile for tube, pipe and other structural cuts, dissipating stress during cutting for greater resistance to wear and tooth breakage. In addition, the blades are designed with an exclusive tooth-setting process which minimizes pinching when cutting structural and bundled materials. The blades are available in widths of 3/4″, 1″, 1-1/4″, 1-1/2″, 2″, and 2-5/8″, and can be used with manually operated, gravitational, and hydraulic machinery, making them a versatile and adaptable choice for a variety of applications.

The TENNAX-PRO Band Saw Blades replace the Starrett Versatix™ MP line.

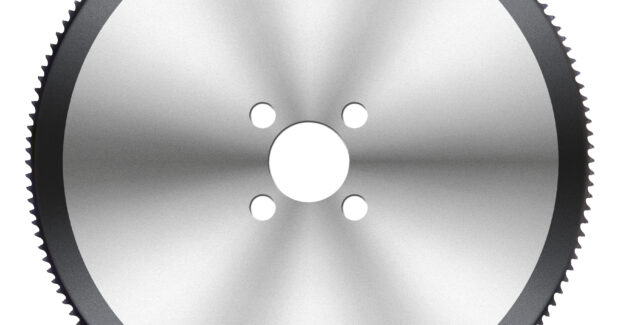

Innovative and High Performance Circular Saw Blades

Wikus Saw Technology Corp.’s (Addison, IL) precision circular saw blades for the cutting of tubes and profiles feature advantages such as variable tooth pitch, an innovative tooth geometry for the interrupted cutting channel, a high-cutting performance, and they are carbide tipped with hard material coating.

The KREOS® is a circular saw blade with variable tooth pitch for thin-walled steel pipes and profiles. These blades set standards for processing thin-walled pipes and profiles with small cross-sections and are highly suitable for cutting applications in mass cut production processes as well. The innovative specific chip space geometry with small variable tooth pitches based on the WIKUS joint technology lends the KREOS blades properties that are unique in the market. The blades stand out due to their excellent cutting performance, which is up to 40% higher than competitive products. Other advantages include a reduction in cutting costs, excellent surface quality, fewer saw blade changes and machine downtime, as well as a reduction of sawing noise.

Another circular saw blade from Wikus is the MIRUS®, a high-performance innovative blade that provides a solution for rust- and acid-resistant thin-walled pipes and profiles. These blades optimize sawing processes with a new cutting geometry, a small variable tooth pitch and a unique number of carbide-tipped teeth. The MIRUS is in a class of its own in the market with respect to productivity, cost savings and surface quality. Advantages include reduction of tool costs, fewer saw blade changes, and fewer finishing processes.