New 30 kg Payload Cobot Launches and Sets a new Era and Standard in Automation

Despite its compact size, Universal Robot’s new UR30 offers extraordinary lift, and its superior motion control ensures the perfect placement of large payloads allowing it to work at higher speeds and lift heavier loads.

Posted: November 30, 2023

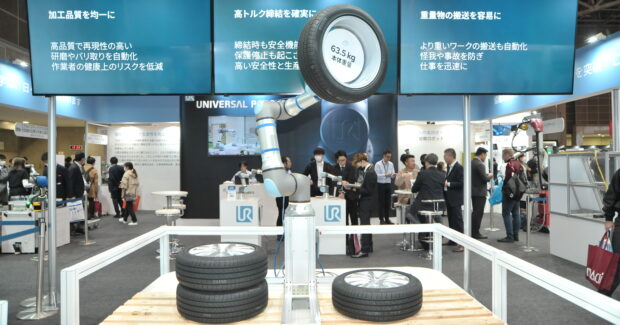

Universal Robots, the Danish manufacturer of collaborative robots (cobots), has announced that it will expand its leading product portfolio with a new 30 kg payload cobot. The UR30 made its global debut at iREX 2023 in Tokyo, Japan.

UR30 is the second in Universal Robot’s new series of innovative, next generation cobots and is built on the same architecture as the award-winning UR20. Despite its compact size, UR30 offers extraordinary lift, and its superior motion control ensures the perfect placement of large payloads allowing it to work at higher speeds and lift heavier loads.

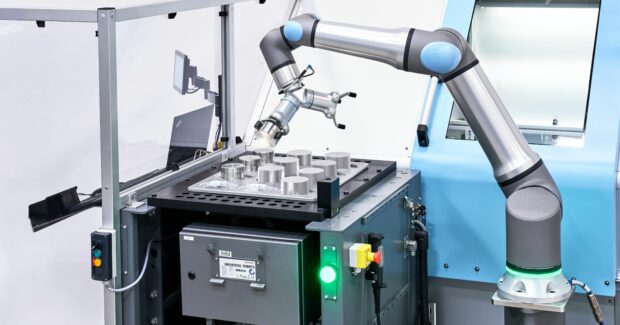

This makes UR30 ideal for several applications, including machine tending, material handling and high torque screw driving. For machine tending, the high payload brings new possibilities as it allows the cobot to use multiple grippers at the same time. This means it can remove finished parts and load more material in one single pass, shortening changeover times and maximizing productivity.

UR30 will also effectively support high torque screw driving as it can handle larger and higher-output torque tools, and thanks to a steady mode feature UR30 delivers straight and consistent screw driving. This will be beneficial in, for example, the automotive industry.

In addition to this, the 30 kg payload makes UR30 a great match for material handling and palletizing of heavy products across all industries, with the small footprint enabling it to fit into almost all workspace – relieving humans of the heavy lifting. Weighing only 63.5 kg, it can also be easily moved between work cells.

The company’s President, Kim Povlsen, says: “The higher payload and greater flexibility underpin a new era in automation. Industries around the world are embracing more agile manufacturing and modularity in production – part of achieving that modularity and agility is about mobility and this cobot delivers that despite its payload.

“As industries evolve, the UR30 not only meets but anticipates shifting demands, enabling businesses to adapt and respond to changing needs effectively. As we continue to innovate, the UR30 is another step in UR’s journey in pushing the boundaries of what is possible in the world of automation.”

The UR30 is available for pre-orders now and will begin shipping in Q1 2024.