New Ceramic Indexable Inserts for Turning and Milling Super Alloys

The new Walter WIS30 ceramic grade is proven to be efficient and reliable. Suitable turning and milling applications include roughing, semi-finishing and finishing, as well as interrupted cuts.

Posted: November 14, 2023

The new indexable inserts made of the WIS30 ceramic grade from Walter are versatile in both milling and turning operations. Based on the elements silicon (Si), aluminum (Al), oxygen (O) and nitrogen (N), the SiAlON ceramic inserts with high aluminum content are effective when machining super alloy materials (ISO S workpiece group), such as Inconel 718, Rene, Hastelloy and Waspaloy.

Suitable turning and milling applications include roughing, semi-finishing and finishing, as well as interrupted cuts. The axial depth of cut (ap) is up to 0.197 in. (5 mm). The ceramic indexable inserts with chamfer have a rounded cutting edge (hone E) for a soft cutting action or a tough cutting edge (T-land T01020) for heavy-duty machining operations.

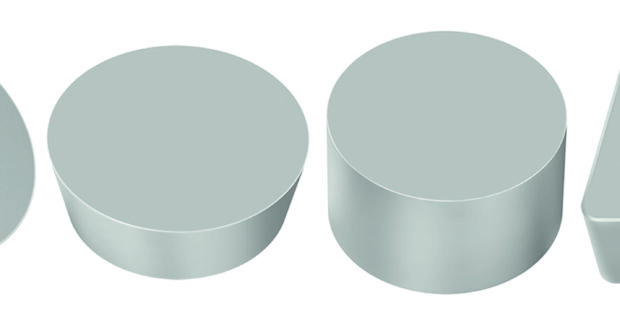

The insert styles include C-style inserts and round inserts (CNGN, RCGX, RPGN and RNGN). CNGN, RNGN and RPGN are standard ISO negative and positive inserts without a screw hole, while the RCGX is a positive clearance insert with a triangular prismatic base for exceptionally strong insert pocket. The high aluminum content in the SiAlON ceramic grade enables a high level of heat resistance, which is particularly beneficial when turning and milling of super alloys. Longer needle shaped grains and finer grain size compared to WIS10 grade makes the WIS30 grade much higher in toughness allowing the WIS30 grade to tackle tough applications such as turning of castings with scales and milling applications. In addition, the inserts reduce the cost per cutting edge because of their long tool life.

For milling applications, two new ceramic insert mills have also been released. The M2472 holds positive inserts (RPGN) and M2473 is designed for negative inserts (RNGN). Both the milling holder families have coolant vents for carrying compressed air to extend the tool life of the inserts.

Walter, a global leader in the metalworking industry for over 100 years, offers a wide range of precision tools for milling, turning, drilling and threading applications. The company helps customers in the aviation and aerospace industries, automotive, energy, and general metalworking industry improve process reliability and increase productivity. As an innovative partner capable of creating digital process solutions for optimal efficiency, Walter is pioneering Industry 4.0 throughout the machining industry.