Hold Tight: Leverage Advanced Positioners for Secure Workholding

Efficient and adaptable workholding tools create significant improvements in metalworking applications.

Posted: January 4, 2024

Innovations in vises, positioners, clamps and workholders result in solutions that prolong and optimize machining processes.

Updates to Clamps Optimize Overall Product Performance

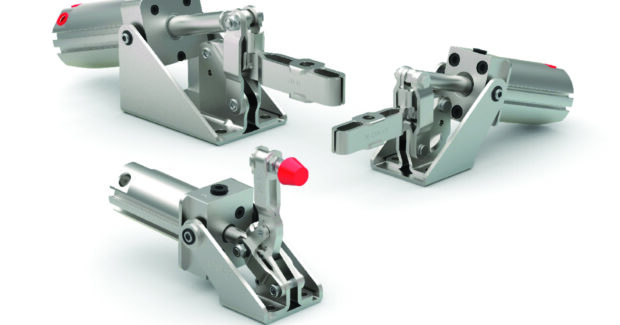

DESTACO’s (Auburn Hills, MI) quality enhancements for three models within its 800 Series manual clamp product family are in line with its commitment to review and identify ways to improve the capabilities of its products, with the goal of achieving the highest level of performance. Receiving the most extensive quality enhancements is the Model 802-U manual clamp. The updates include an upgraded air cylinder that ensures the clamp’s exerting force is less than the maximum holding capacity when operated at normal pressure, which extends service life; new composite bearings on the trunnion mount and cylinder pivot point that eliminate metal-to-metal contact while requiring no lubrication; and a redesigned clevis bolt, along with increased rivet and pre-stop diameters that increase longevity.

The other improved clamps include the Model 807-U and the Model 810-U. The Model 807-U now features lubrication- and maintenance-free composite bearings on the trunnion mount, a redesigned clevis bolt and a reconfigured base, resulting in the elimination of any hesitation that could compromise the unit’s open/close performance. The Model 810-U features new composite bearings that eliminate metal-to-metal contact, thereby extending service life, while requiring no lubrication or maintenance.

New Nutrunner Clamps for Automated and Robotic Production Lines

Fixtureworks (Fraser, MI) has expanded its line of nutrunner clamps to include pull-down clamps for 5-axis machines, spring loaded heavy-duty supports, and extensions for each. The Nutrunner PTPD1 pull down clamps provide quick and secure fastening and are ideal for 5-axis machines and workpiece machining, particularly on horizontal machining centers. The heavy-duty work support PTNS1 is ideal for preventing the workpiece from chattering and deflecting. The PTRC1 extension units are suitable for operating PTPD1 pull down clamps and PTNS1 work supports from a distance. Attach an extension bar and hex socket to connect the extension unit to the clamp or work support.

MQL Efficiency Added to Tool Holding System

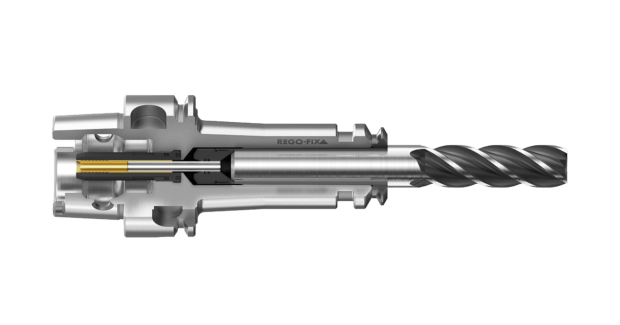

REGO-FIX (Whitestown, IN) has added minimum quality lubrication (MQL) machining to its industry-leading powRgrip® tool holding system. Doing so reduces coolant consumption and shortens cycle times for improved production and tool life. In addition to significantly reducing coolant consumption, MQL machining has been shown to reduce cycle times by 25%-to-85%, improve chip evacuation for better surface finishes and tolerances while also increasing tool life.

The standardized MQL PG collets are designed for tool shanks according to DIN 69090-3 and available for HSK-A 63 and HSK-E 40 tool holders. They are designed for machines using one-channel, internal through-spindle MQL systems and are beneficial for virtually any machining application.

MQL PG collets combine the efficiency and performance of MQL through-spindle cooling and lubrication with standard innovative features that further enhance the PG tool holding system. Without the use of heat or hydraulics, PG tool setting units apply up to 1,100 Nm of clamping torque with a hydraulic press to accomplish tool changeouts in under 10 seconds for complete operator safety. The PG holder and collet provide excellent vibration damping and will maintain total indicated runout of less than 0.0001” through five years or 20,000 cycles with no erosion of impregnated surface treatment.

New Long Turning Tool Holders Extend Tool Life on Swiss-style Automatic Lathes

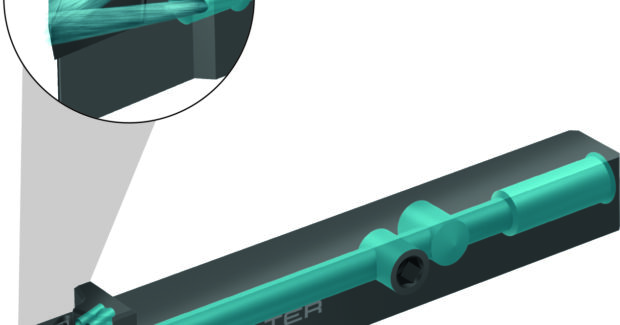

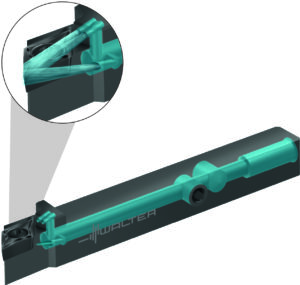

Walter USA LLC’s (Greer, SC) new Walter Turn Swiss tool holders for turning applications, target applications on Swiss-style automatic lathes and multi-spindle machines that have up to 2,175 psi (150 bar) of coolant pressure. The holders are suitable for turning high-precision parts, longitudinal (axial) turning, facing and copy turning small-diameter components.

The holder provides targeted clearance face cooling for efficient chip control and increased tool life in addition to high precision cooling on the flank face to slow down the insert heat and wear. The holders feature a flexible coolant connection in three positions for either external plumbing or thru-coolant introduction through late turrets. The holders accept CCGT3xx, DCGT3xx and VCGT2xx indexable inserts and provide a high level of indexing accuracy even when turning parts with tight tolerance specifications.

Potential benefits include less downtime caused by bird nesting of chips thanks to the targeted clearance face cooling and long tool life even when turning heat-resistant workpiece materials due to the cooled cutting edge.