Moving Manufacturing Forward Through Educational Partnerships

With internal and external education, outreach, and training, younger workers can take their knowledge and help move the manufacturing industry forward, resulting in fresh processes and innovation.

Posted: January 3, 2024

More than 12.7 million U.S. workers were employed in manufacturing in 2022, according to the U.S. Bureau of Labor Statistics. However, recruiting and retaining talent remains a top priority — and challenge — for manufacturing leaders. A key driver is nearshoring, which brings manufacturing operations stateside to improve supply chain logistics. With an influx of plants and new jobs, manufacturing leaders are scrambling to fill roles. There’s already a projected 2.1 million jobs that will be unfilled by 2030 as a result of a lack of skilled labor, according to www.census.gov. Ultimately, implementing effective recruitment and retention strategies is possible but can only be achieved with strong education and training initiatives.

Get Workers Onboard Early

Attracting the next generation of workers and ensuring they have the skills they need requires institutional partnerships. One of the most effective recruiting practices manufacturers can partake in is university, college, and high school training programs. These programs include having up-and-coming workers apprentice at manufacturing plants and inviting manufacturing leaders into classrooms to highlight where the industry is headed. Educational partnerships can help manufacturers build early talent pipelines, give students the skills they need to have a fulfilling career, and develop brand loyalty early on.

Emerging Technologies Require Emerging Programs

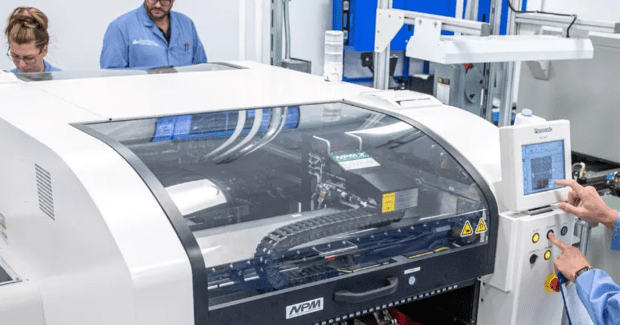

Closing the skills gap can be challenging, as more and more emerging technologies become integrated into the manufacturing line. Today, 84% of manufacturers have adopted smart manufacturing or are actively evaluating solutions with the goal to implement in the coming year.1 This includes tools like advanced analytics, modeling and simulations, the Internet of Things, and so much more. For students to be prepared for the workforce, they must have comprehensive knowledge of these tools — from how the tech works to how it’s used in manufacturing. Students need to understand how the tech helps manufacturers keep up with growing demands, boosts productivity, and captures key data points to make processes more efficient. They also need to learn how to work effectively with machines as automation only continues to increase. In addition, students need to understand how to work with software solutions such as ERP (enterprise resource planning), which deliver real-time visibility into supply chain operations while also providing reporting tools to maintain compliance.

For those who aren’t interested in the traditional college or university experience, technical programs are also highly valuable in developing trade-based skills. With faster graduation timelines and smaller class sizes, students get more hands-on experience and enter the workforce more quickly.

While manufacturers can close the skilled labor gap by preparing the next generation earlier, they must also encourage continual education once the next generation is on the job. Not only is it important to keep workers’ skills sharp, but upskilling also helps retain the employees you worked hard to recruit. Forty-two percent of workers identify training and career opportunities as a key reason they stay at their job, and two-thirds of those under 25 say it’s a motivating factor in whether they stay with their current company.2

Don’t Ignore Your Existing Employees

While there is a large emphasis on attracting and retaining the next generation, it’s just as important to put resources towards strengthening current employees’ experiences. Today, according to the U.S. Bureau of Labor Statistics, the median age of the U.S. manufacturing workforce is 44 years old, so most workplaces consist of experienced workers. Employers can’t afford to lose these employees prematurely while closing the labor gap.

Just like incoming workers, current employees need opportunities to uplevel their skills. Learning and development comes in many forms, whether it’s dedicating time during an employee’s schedule to focus on skills training or providing financial support to help workers further their education.

When presented with upskilling opportunities, employees feel like their success is valued. This improves job perception, while making workers feel more secure in their role as they have the skills to succeed in the transforming market.

The Role of Workplace Mentorship

Over the next couple decades, there will be a critical overlap between the traditional and new manufacturing workforce. This presents a unique opportunity for manufacturers to position their mature workforce as mentors to up-and-coming staff. Having been in young employees’ shoes, existing employees can pass along institutional knowledge, including equipment maintenance advice, customer expectations, and more. This helps new employees build on the wisdom of their experienced coworkers. By the same token, early career workers can bring new ideas to the table. Through mentorship programs, senior employees can acknowledge how the industry has grown and the areas they see growing in the coming decades.

Preparing for the Future, Today

The manufacturing industry is experiencing a whirlwind of changes as it continues to rebound from the pandemic. The approach to retention and recruitment must change with it. With education, outreach, and training, younger workers can take their knowledge and help move the industry forward, resulting in fresh processes and innovation. By prioritizing the employee experience for both new and current employees, manufacturers have a greater chance of attracting and retaining top-level talent in the long term.

End Notes

- “Believe the Hype: The Current State of Smart Manufacturing,” posted at saca.org.

- “Manufacturing Engagement and Retention Study,” posted at themanufacturinginstitute.org.