New Grades Available to Reliably Drill Aluminum Alloys

The Walter grade WNN15 (PVD coated) and WN15 (uncoated polished) are available for indexable insert drills.

Posted: January 26, 2024

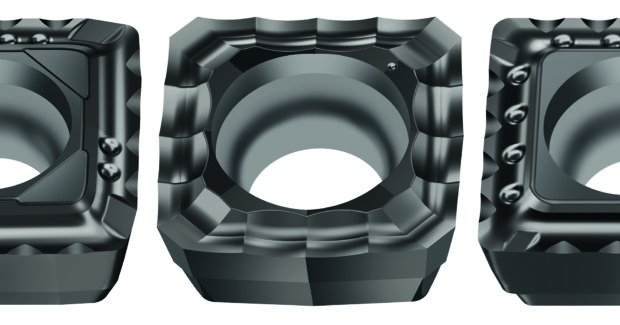

WNN15 grade from Walter is an extremely reliable, low-adhesion grade that is now also included in the company’s indexable insert drills. The drills that accept indexable inserts made of grade WNN15 include D4120, D3120, and B3212.DF. to B3214.DF in insert versions P4840, P2840 and LCGX.

The grade is primarily designed for drilling wrought or cast aluminum alloys (ISO N workpiece group). Applications for these alloys are mainly found in the aerospace and automotive industries, as well as in general mechanical engineering.

The drilling grade WNN15 features a hard substrate, which ensures outstandingly high cutting-edge strength and sharpness on indexable inserts. In addition to exceptional process reliability, the inserts offer a high level of wear resistance to provide long tool life even at extremely high cutting speeds. An increase in tool life of up to 200% can be achieved compared to conventional drilling grades, depending on the application. These capabilities make drilling with the grade WNN15 indexable inserts more cost-effective than comparable PCD tools.

A physical vapor deposition (PVD) coating is applied to the grade WNN15 inserts using the high-power impulse magnetron sputtering (HiPIMS) process to create an incredibly smooth, dense surface. The rake faces are also polished. As a result, chip evacuation is smooth and built-up edge (BUE) is avoided on the tool/workpiece interface. The inserts are also very cost efficient due to 4 indexes per insert.

Additionally, Walter has introduced uncoated polished grade WN15 with a fine-grained substrate also suitable for aluminum machining. This uncoated grade WN15 complements the coated PVD grade WNN15 described above but serves as an ‘economical alternative’ with approximately 30% lower cost/cutting edge. The drills that accept WN15 grade inserts include D4120, D3120, and B3212.DF. to B3214.DF in insert versions P4840, P2840 and LCGX.

About Walter

Walter, a global leader in the metalworking industry for over 100 years, offers a wide range of precision tools for milling, turning, drilling and threading applications. The company helps customers in the aviation and aerospace industries, automotive, energy, and general metalworking industry improve process reliability and increase productivity. As an innovative partner capable of creating digital process solutions for optimal efficiency, Walter is pioneering Industry 4.0 throughout the machining industry. With Regional Headquarters in Greer, SC, Walter markets its competence brands Walter, Walter Titex, Walter Prototyp and Walter Multiply through a network of channel partners and field engineers across the USA, Canada, Mexico and Brazi.