Cost-effective Monitoring Systems Provide Thorough and Clear-cut Assessments

Make timely decisions regarding tool changes and adjustments to machining parameters with powerful monitoring systems.

Posted: February 15, 2024

Leading edge monitoring and inspection systems create a more robust and accurate inspection workflow, improving your shop’s product quality and minimizing costly disruptions.

Solution Brings Hybrid AI, 3D Imaging, and More to Robotic Inspection

Kitov.ai’s (Petah-Tikva, Israel) K-BOX line consists of cost-effective machine vision systems that combine AI, 3D imaging, and intelligent robotic planning technologies to solve demanding inspection applications. Kitov.ai’s K-BOX offers the same functionality as its Core+ solution. However, instead of shipping with an industrial robot, K-BOX offers APIs that connect Kitov software to virtually any standard or cobot on the market, allowing customers to add advanced visual inspection capabilities to their existing robotic solutions. Customers have the choice of choosing the brand and the size of the robot according to their needs. “K-BOX is part of Kitov.ai’s efforts to make powerful, deep-learning machine vision software available to every customer segment by focusing on the capabilities of integrated software rather than dedicated robot software,” said Aviel First, Kitov’s CEO. “With K-BOX, our customers can field hybrid machine vision systems without having to adapt to robotic platforms that may not be part of their in-house robotic specifications or expertise.”

New Subscription Service for 3D Fixture Modelling Software

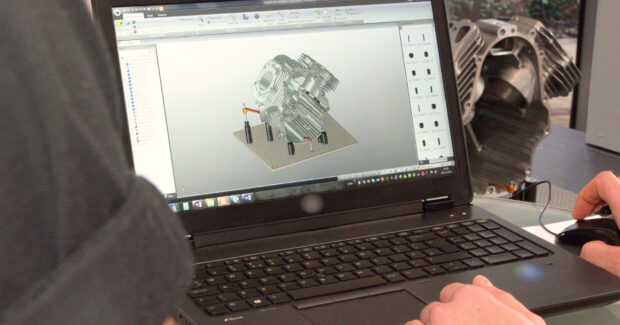

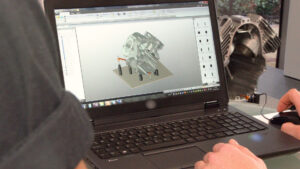

Renishaw, Inc. (West Dundee, IL) is a world leading supplier of measuring systems and manufacturing systems. Its FixtureBuilder 3D fixture-modelling software is now available via a new subscription service, and customers can take advantage of a complimentary 12-month subscription to this highly accessible fixture-planning software when they purchase qualifying metrology fixturing products or bundles. The user-friendly software allows quick creation and documentation of advanced CAD-based metrology fixturing set-ups for repeatable and productive part inspection. Users have access to the full catalogue of Renishaw metrology fixturing components when designing and documenting their modular fixturing setups.

The FixtureBuilder software boasts an intuitive interface, complete with clear and well-organized component libraries, intelligent drag-and-drop functionality, and an easy-to-use constraint mechanism. Its full CAD compatibility and custom libraries further enhance the user experience, and the software’s standout feature is its “Build It” function, which automates the generation of work instructions and bill of materials for each fixture setup.

“Our fast and flexible FixtureBuilder software is a powerful addition to any manufacturer’s inspection workflow,” said Will Paul, product marketing manager for Renishaw. “The weakest link in an inspection process is often the ability to design and document comprehensive fixturing setups with ease and speed. FixtureBuilder gives our customers confidence in the positioning of their parts.”

FixtureBuilder 8.1 is the latest version of this popular software. It enables design of fixturing setups in seconds and then exports them to inspection programming software of choice, using popular file formats like IGES, SAT and STEP. This ensures seamless functionality and compatibility with industry-standard inspection programs and applications.

New Rigid Industrial-grade Micro Fiberscopes

Titan Tool Supply Inc. (Buffalo, NY), a worldwide supplier of optical instrumentation and precision micro-finishing tools, offers its L-Series, a family of rigid industrial-grade micro fiberscopes, also known as fiber optic borescopes.

The L-Series is designed to perform accurate and reliable remote visual inspections and diagnostics in hard-to-reach, remote, or otherwise inaccessible areas — all without the need for machinery and equipment disassembly or disruption. The series is offered in two unique models: the Model L-1, featuring a 1 mm diameter, 42° field of view, and a 6” working range; and the Model L-2, featuring a 2 mm diameter, 50° field of view, and a 12” working range. The overall focal length range is 0.118″-to-0.236″ (3 mm-to-6 mm).

The durable construction of both L-Series models consists of a long, thin, and rigid stainless-steel tube body. The tube features a lens on one end and a light source (sold separately) on the other. The tube further contains an optical fiber bundle that transmits light from an external light source, thereby illuminating the area under inspection. The image is then transmitted by the fiberscope lens to an eyepiece or camera for remote viewing and diagnostics. To ensure superior optical resolution for the chosen diameter size, the Model L-1 is offered with a 6K element imaging bundle, while the Model L-2 features a 10K version. Both models can be fitted with an optional 90° viewing tube, resulting in only a small increase in the overall tube diameter. Both feature 30X eyepiece magnification for optimal resolution.

The L-Series models are ideal for a variety of applications, including industrial machinery and equipment and their related internal component inspections; automotive maintenance (including interior inspections of engines, cylinders, and other hard-to-reach areas of the vehicle, as well as the detection of leaks, cracks, or blockages; aerospace maintenance (for the inspections of aircraft engines, fuel lines, and other critical components and equipment); pipeline monitoring, and virtually any other general-purpose industrial-grade remote visual inspection and diagnostic application. The models identify potential defects, damage, and sources of wear and tear, and especially in hard-to-reach, remote, narrow, or otherwise inaccessible spaces, in order to prevent costly downtime.