Dynamic and Responsive CAD/CAM Software Translates into Quality Products

Through ease of use and increases in simplicity, CAD/CAM software is equipped with powerful features to meet the complex requirements of the metalworking industry.

Posted: February 20, 2024

Customer feedback and industry insights play a crucial role in shaping CAD/CAM software updates, for example in regard to multi-axis and mill-turn capabilities and optimizing toolpaths for efficiency and speed.

Spiraling Material Costs Pressure Fabricators to Reduce Waste

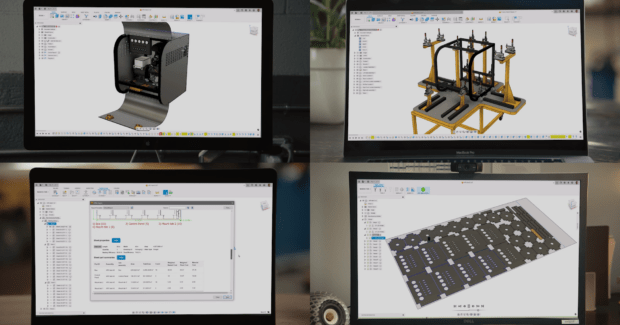

CAD/CAM software is increasingly vital in the fabrication industry, providing automated tools for efficient component nesting and arrangement, enabling cost-analysis, and optimizing production. With the cost of raw materials increasing, companies such as Ganas Manufacturing are turning to software, like Autodesk Inc.’s (San Francisco, CA) Fusion and reducing scrap rates from 25% to 5%. “The impact of nesting in Fusion has been huge for our designers and manufacturing team,” said Richard Ganas, CEO, Ganas Manufacturing.

Beyond waste reduction, automation offers transformational gains, improving production consistency, simplifying machine setup, and shortening project delivery times, ultimately helping fabricators to deliver a higher value service. And when inevitable last-minute design updates happen, automation can cascade changes through to production ensuring everyone is working on the correct data.

However, real success lies in collaboration. Cloud-enabled tools in software like Fusion facilitate communication across internal and external teams, allowing business-critical decisions to be made whether teams are in the next room, the next town, or a different country.

The shift from manual processes to automation and collaboration through CAD/CAM software is transforming the fabrication industry, making it more efficient and cost-effective, and allowing businesses to thrive.

Autodesk Fusion provides integrated CAD/CAM workflows and cloud-enabled collaboration to enable manufacturers and fabricators to make better use of their data, people, and equipment. Fusion’s intuitive interface helps maximize material utilization, reduce waste, and shorten production time.

www.autodesk.com/products/fusion-360/fabrication

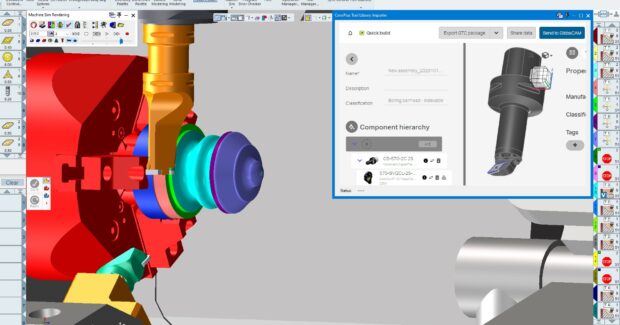

Powerfully Simple, Simply Powerful: Enhancements Result in Stronger Connectivity

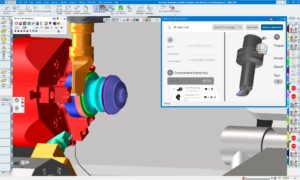

GibbsCAM’s (Thousand Oaks, CA) GibbsCAM 2024 features a number of significant enhancements to core strengths while bringing a stronger emphasis on digital connectivity. Version 2024 unlocks the power of Sandvik Coromant through a direct integration with the CoroPlus® Tool Library, providing access to the right cutting tool for your specific operation and offering instant cutting data recommendations. It provides up-to-date cutting tool data, 3D models of cutting tools and holders, and essential information to make informed decisions for optimized manufacturing processes. All data is verified and adheres to the ISO 13399 international standard for cutting tool data representation and exchange. The cloud-based nature of the tool library means that users of GibbsCAM 2024 can access data from anywhere with an internet connection, making it invaluable for organizations implementing company standards, or users who work remotely or across multiple locations.

Efficiency remains a primary focus, with the introduction of new post-processor configuration options for setting standard and custom post defaults, including support for TCP or Rotary clamps. Furthermore, a new tool to streamline the setup of the CAM environment now enables editing and restriction of work fixture offsets. GibbsCAM 2024 supports multiple fixture stacking, and now unused fixtures can be retained on the machine for simulation and collision checking purposes.

Working with CAD data is easier. Users can interrogate virtual points for dimensioning part geometry such as edge mid points, end points, intersection, circle center, and circle quadrants directly from the 3D model. A newly introduced visualization tool can map the curvature and the relevant taper/draft angle directly onto the 3D model. This is a particularly useful tool for analyzing the minimum tooling diameter required to cut a part since it negates the need to pull extra reference geometry.

Visit the GibbsCAM website for complete details about the enhancements to the software.

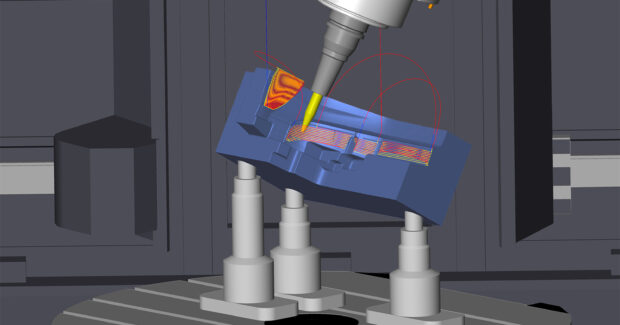

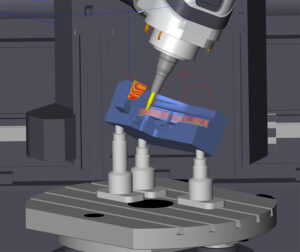

Highly Productive Programming Strategies Result in Accuracy

Open Mind Technologies’ (Needham, MA) latest hyperMILL® CAD/CAM software suite features highly productive programming and machining strategies, which enable accurate, efficient 2.5D, 3D, precision 5-axis and mill/turn machining. hyperMILL VIRTUAL Machining provides postprocessing, and G-code simulation including a VIRTUAL Machining Optimizer, which improves toolpaths that are traditionally calculated in the CAM engine. The Optimizer also incorporates knowledge of the part model, tooling, the toolpath calculation and collision check engine, and the machine tool model (a.k.a. digital twins) with its physical constraints. New, improved linking logic in the Optimizer for 5-axis table-table machines is also available. The Optimizer module links individual part programs by automatically calculating smooth and safe connections between a retract move and subsequent insert, including optimization of clearance planes.

hyperMILL Automation Center allows users to automate job list creation processes in hyperCAD®-S and is available as a development or runtime environment. New features also include the ability to select and position a clamping device, as well as define a uniform process for all programmers.

Drive High Quality and Predictable Output at the Machine

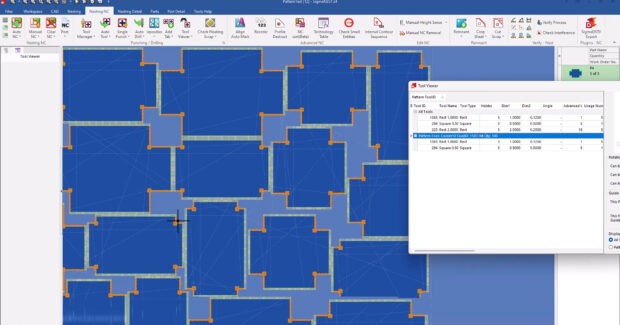

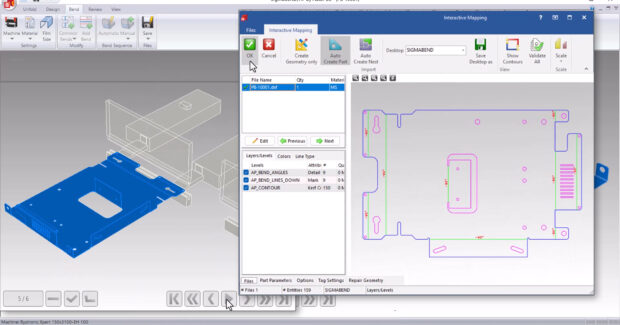

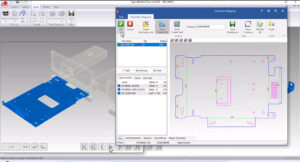

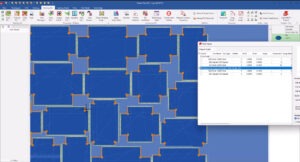

SigmaNEST (Cincinnati, OH) a leading innovator in CAD/CAM, shop floor, and business software for the fabrication industry, offers version 24 of the software suite. The new release gives fabricators the tools to reach higher productivity throughout the shop, while being easy and intuitive to use.

New features include:

- The new SigmaBEND AP integration improves the automatic transfer of bending data for part creation, time estimation and quoting into the Connected Shop.

- The new SigmaTUBE 24 for SOLIDWORKS integrates completely with the SigmaNEST platform, including powerful new access to the jobs and inventory system.

- The new SimTrans 24 gives customers and IT personnel the tools needed to customize data connections to streamline their operations.

- The SimTrans Studio window gives users access to settings for app integrity, SigmaNEST license configurations, databases and plugins, hardware environment, and shortcuts.

For laser, plasma, oxyfuel and other profile cutting processes, SigmaNEST 24 defines the part profile sequence for any time that part is cut. This one-time setting at the part level reduces programming effort, improves process reliability, and produces predictable cutting results.

SigmaNEST 24 adds punch tool recognition into the HD SuperNest engine for auto nesting and auto tooling for punch and punch-combi operations. The new Elastic Tooling expansion can detect similar use cases for any part regardless of size and automatically suggests using the specified tooling for that part feature.

For complete details on the benefits of SigmaNEST24, visit the SigmaNEST website.