Sawing Systems Optimize Cutting Parameters and Monitor Cutting Processes

Real time monitoring systems track the performance of band saws, correcting the process to minimize disruptions.

Posted: February 15, 2024

Sawing systems suppliers manufacture durable and innovative products, which incorporate AI for example, to increase your shop’s cutting efficiency. Listed below are sawing systems that will boost your productivity.

The World’s Most Popular Automatic Vertical Tilt-frame Saw

AMADA MACHINERY AMERICA, INC. (Brea, CA) takes great pride in its legacy, and it is the company’s drive and commitment to continuous improvement that sets them apart. AMADA MACHINERY’s products continually thrive, thanks to its wide array of industry-leading vertical and horizontal band saws, ironworkers, material handling systems, blades, parts and much more. The company works to achieve simplicity and strength in construction, speed, and accuracy of operation, and durability to help you save time and make money over the long run.

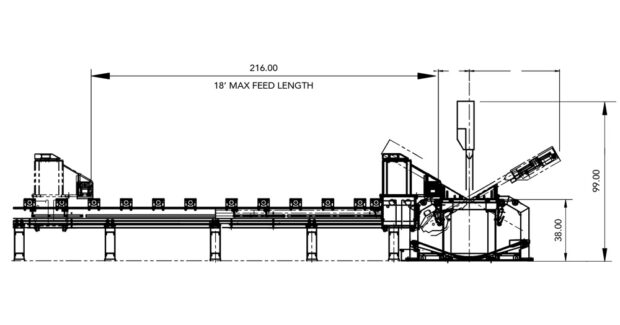

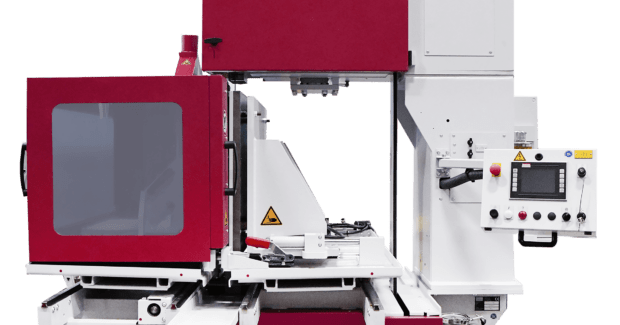

The VT5063SW is the world’s most popular automatic vertical tilt-frame saw. It’s heavy-duty cutting capacity of 20”-x-25” and blade width of 1.5” makes it highly competitive with cutting solid and structural steel. This automatic indexing saw miters up to 60° both left and right with a zero to three degree canted column, for increased efficiency in cutting structural materials. It features a patent PC3 Programmable Control that offers graphical part programming with memory for up to 500 jobs and parts, as well as a material selection chart and customizable material library.

This Vertical Tilt-Frame is manufactured in Oshkosh, Wis. and you can customize it to fit your needs. It offers an optional long stroke shuttle with an extended feed system available for 8-foot, 13-foot, and 18-foot lengths. On top of that, it also offers, a new Offline Programming feature. This new feature can be purchased to work in conjunction with the VT5063SW saw that utilizes the PC3 saw controls.

Innovating the Future with Vertical Band Saw for 3D Printing Plates

Behringer Saws, Inc.’s (Morgantown, PA) LPS-T 3D vertical band saw was developed for sawing 3D printing plates in various sizes up to 47.2”-x-47.2”. The individual production of the work holding according to customer requirements offers a high degree of flexibility when sawing 3D printing plates in different sizes and shapes. Parts are removed squarely and flush to the plate with a clean, burr-free cut and excellent finish. With its movable support table and NC-controlled workpiece holding, even heavy 3D printing plates can be easily loaded and unloaded using lifting gear.

In order to optimally adapt the sawing system to the specific process, Behringer offers various options such as a machine housing with extraction option, minimum quantity lubrication, as well as individual clamping options according to customer requirements. The LPS-T 3D is the fastest removal solution available, while also delivering precision with low capital investment and operational costs compared to any other technology. Image courtesy of Behringer Saws.

Revolutionize Precision Cutting with Powerful Band Saw Solution

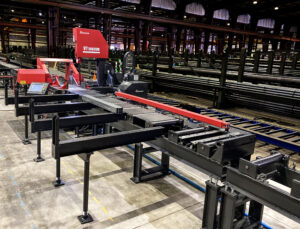

Unleash the seasoned prowess of the DoALL Sawing Systems’ (Savage, MN) Hercules DC-540CNC-A, meticulously crafted for fabricators and metalworking enthusiasts seeking a reliable companion in their business. Designed for extremely high production, this automatic and hydraulically controlled machine offers time-tested performances in industrial settings.

Key features include:

- Efficient Production: Engineered for extreme high production environments, ensuring efficiency in every cut.

- Automated Precision: Highly efficient and automatic with hydraulically controlled operations, offering seamless performance.

- Industrial Versatility: Ideal for serial production in industrial settings, providing reliability and flexibility.

- Robust Construction: Crafted with a robust construction, allowing precise cutting of a wide range of materials.

- Versatile Cutting: Cuts full and profile materials, including stainless and tool steel, highlighting its versatility.

The Hercules DC-540CNC-A is backed by a one-year parts and service warranty. It is a reliable and powerful solution for your high-production band sawing needs, ensuring efficiency and accuracy in every cut.

AI in Band Saw Controls Ensure Predictive Responses, Increasing Efficiency and Productivity

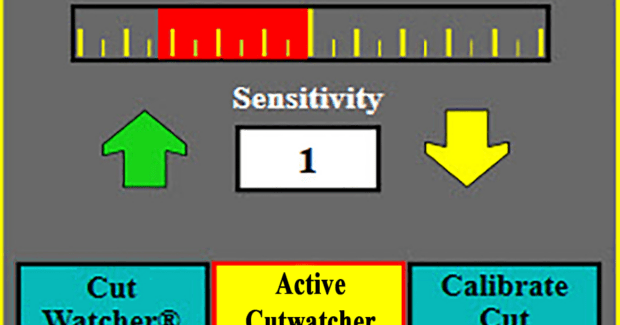

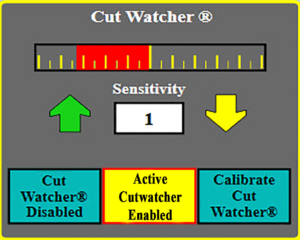

Band saws, like other metalworking equipment, have increased technologically. HE&M Saw’s (Pryor, OK) updated Cut Watcher® feature, called Active Cut Watcher®, not only monitors the straightness of the cutting but also takes steps to correct it.

The new Smart Saw® control and Smart Saw Connect® are newly created or improved. The Smart Saw Connect will be compatible with MTConnect®, the non-proprietary manufacturing technical standard designed allowing data to be exchanged between software applications and equipment on the shop floor. HE&M Saw engineers are also working on incorporating aspects of artificial intelligence (AI) into the controls and other systems on saws and material handling systems. The common method of operation is ‘reactionary’ rather than ‘proactive.’

With the incorporation of AI into the controls, software will accumulate data, analyze it, and use it to respond in a more predictive manner. The ability to be predictive can help prevent job interruption due to a catastrophic equipment failure.

Our efforts are geared around designing and manufacturing equipment that will last longer, perform more efficiently and be more productive, providing a much faster ROI for our customers. Being innovative and generating systems such as Smart Saw Connect ensures the customer is getting equipment that will accomplish that goal. — Paul Beha, products manager, HE&M

Achieve Precise Cuts and Efficiencies with the Latest Technologies and Automation

KASTO, Inc.’s (Export, PA) band saws and circular saws cut bar materials, sheet metals and profiles with straight or miter cuts. In addition to high cutting efficiency, users require low idle periods. In response to these demands, parameters such as material qualities and the saw band tailored to them can be stored permanently on the KASTO saws. The control system automatically selects the cutting technology appropriate to the specific job. Not only does this reduce tool costs, it also significantly reduces cutting times. CNC-controlled, fully automated production circular saws like KASTOvariospeed can cut any bar stock to size, regardless of material quality. Where required, the sawing solution can also work in conjunction with the KASTOsort robot handling system.

Always available is the KASTOapp, which provides users a complete status overview of all KASTO sawing machines in the network. All-important parameters, such as article, cut length, target and actual number units, and cutting speed are accessible at any time. KASTOlogic mobile assists personnel in the storage system. By scanning QR and barcodes, for example, you can easily trigger a repeat order when removing items from the magazine. The app notifies users in the event of an operational error, enabling a rapid response.

Band Saw Blades Cut a Wide Range of Materials and Shapes

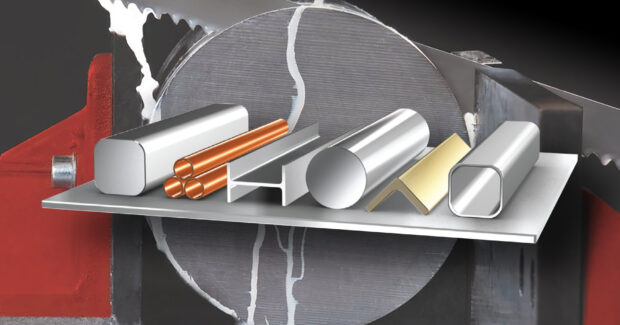

The L.S. Starrett Co. (Athol, MA), a global manufacturer of precision hand tools and gauges, power tool accessories, saw blades and more, offers IntenssTM Bi-Metal Band Saw Blades for general purpose metal sawing of a wide range of materials and shapes.

Featuring a patented process developed by Starrett called bi-metal unique® technology, which provides 170% more weld contact with the teeth, Intenss blades exhibit superior resistance to tooth strippage, significantly reducing fracture and breakage, which enables exceptionally long blade life. Performance is further enhanced by M-42 teeth with a multi-edge tooth design that produces split chips for faster cutting.

“Starrett Intenss is an ideal affordable workhorse blade for general sawing in toolrooms, maintenance shops and fabricating or machine shop applications where one blade cutting a wide range of common materials with different shapes is a good sawing solution,” said Jay Gordon, Starrett’s North American sales manager for saws. “In addition, bi-metal unique promotes long blade life, so fewer blade changes are required.”

The blades are available in 1/2″, 3/4″ and 1″ widths and .025″ and .035″ thicknesses, featuring bi-metal unique. Blades in 1-1/4″ or 1-1/2″ widths and .035″ and .042″ thicknesses are also available, without the bi-metal unique feature. Intenss blades are offered in pitches of 10, 14 or 18, and 2-3, 3-4, 4-6 and 5-8 variable pitches. Coil lengths are available in 100’ (30m), 150’ (45m) or 250’ (75m), depending on blade widths.

Band Saw Blade is the Solution for Cutting Nickel-based Alloys

Nickel-based alloys are indispensable, especially in the chemical industry, in engine construction, and in power generation, because they can withstand high mechanical, chemical, and thermal loads. Processing in production is correspondingly demanding. WIKUS Saw Technology Corp. (Addison, IL) addresses the extremely difficult-to-cut nickel-based alloys with the FUTURA® 718 carbide band saw blade, which precisely cuts solid materials made of these superalloys.

Applications

- Solid material of steels, which are difficult to cut

- Nickel-based alloys

- Heat-resistant, high temperature-resistant, and duplex steels

Advantages

- Specially developed for nickel-based and similar superalloys

- Optimum chip division for tough and high-strength materials

- Reduced cutting forces for long blade-life and straight cuts

- High consistent cutting rates

- Reduces blade pinching

- Reduces work hardening of the material being cut

- Reduced finishing due to high cut surface quality

Features

- Tooth edges made of optimum carbide for high-strength tough materials

- Precision ground trapezoidal tooth geometry

- Carrier band with special shaping for elimination of work hardening due to special mode of operation

- The band saw blade uses tooth edges with carbide bodies specially designed for high-strength, tough materials. The geometry of the perfectly ground trapezoid teeth is also precisely matched to the cutting of such nickel-based alloys.

- In addition, WIKUS uses a carrier band with special shaping for the high-tech sawing tool in order to eliminate the resulting work hardening of the material in the sawing process. These three factors result in very good cutting rates despite the heaviest machinability and high wear attack.