AMRs and AMVs Create Safer Surroundings and Adjust Workflows Quickly

Improvements in the speed, navigation accuracy, and the safety of autonomous mobile robots create untold opportunities for the metalworking industry.

Posted: April 22, 2024

The integration of AI into autonomous mobile robots (AMRs) provides room to maneuver when it comes to transporting components and products between the different stages of production.

New Levels of Autonomy in AMRs

Earlier this year, ABB’s (Ann Arbor, MI) Marc Segura, who is president of the ABB Robotics Division, commented on the new frontiers for robotics and AI in 2024. One area was how AI will drive new levels of autonomy in robotic applications.

AI is enhancing everything from robots’ ability to grip, pick and place as well as their ability to map and navigate through dynamic environments. From mobile robots to cobots and beyond, AI is giving robots unprecedented levels of speed, accuracy, and payload carrying ability, enabling them to take on more tasks in settings like flexible factories, warehouses, logistics centers and laboratories.

“AI-enabled mobile robots can transform sectors like discrete manufacturing, logistics and laboratories,” Segura said. “Robots equipped with ABB’s new Visual Simultaneous Localization and Mapping (Visual SLAM) technology, for example, have advanced mapping and navigation skills, granting new levels of autonomy, while greatly reducing the infrastructure needed by previous generations of guided robots. This paves the way for a shift from linear production lines to dynamic networks, creating significant efficiencies and taking on more dull, dirty and dangerous tasks, to enable workers to take up more rewarding jobs.”

Next Generation Mobile Robotics

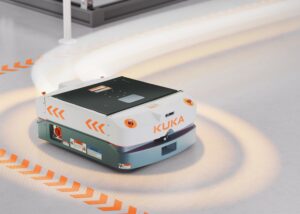

In March, KUKA Robotics (Shelby Township, MI) spotlighted a pair of innovative mobile robots at MODEX 2024. The KUKA KMP 1500P autonomous mobile robot (AMR) platform revolutionizes automation for intralogistic optimization. The KUKA KMP 600-S diffDrive mobile platform automated guided vehicle (AGV) advances industrial logistics with laser scanners and 3D object detection to meet the highest safety requirements.

The KMP 1500P AMR makes an optimal contribution to intralogistic processes in production and storage facilities. With a 60 mm stroke and precision positioning, the AMR transports up to 1.5 tons of materials and workpieces, picks goods, supplies lines and cells with materials, and transports production parts in process linking. The robot uses built-in technology and QR code readers to identify loads. It lifts all types of load carriers for easy implementation into existing industrial projects to optimize warehouse processes, streamline assembly lines and enhance complex material handling.

Differential drive, flexible mobility and the ability to adapt travel paths with autonomous efficiency enable it to handle any dynamic, complex environment. To protect the KMP 1500P, its loads and the workplace, safety provisions include 3D cameras, laser scanners and IP class 54. The KMP 1500P charges both at a charging station and during work processes, with inductive, intelligent 24/7 charging management. KUKA’s KMReS fleet manager greatly simplifies integration for the ideal combination of cost efficiency and safety.

To transport demanding loads, the KUKA KMP 600-S diffDrive mobile platform AGV moves at speeds up to 2 meters per second in all directions of travel and offers up to 600 kg of payload capacity. An integrated lifting device lifts up to 60 mm in under three seconds. The vehicle requires no safety fencing, which provides maximum freedom of movement for employees.

When cycle times require high-speed travel, front and rear-mounted laser scanners ensure safe operation in all travel directions. Camera-based 3D object detection enables the KMP 600-S diffDrive to integrate seamlessly into existing production environments and detect obstacles autonomously from 50 mm up to 2.1 m above the ground. Equipped for tough industrial environments, the product features an IP 54 design that works reliably even in adverse conditions such as water spray and dust.

New Comprehensive Safety Solution for Autonomous Mobile Robots

Pilz (Canton, MI), an innovative leader in machine safe automation technology, has developed a comprehensive safety solution in accordance with ISO 3691-4 for an efficient flow of goods in production and logistics handled by Autonomous Mobile Robots (AMRs). It consists of the safe small controller PNOZmulti 2 with new functionalities for synchronization monitoring and activation, the safety laser scanner PSENscan and the industrial firewall SecurityBridge.

Freely navigating mobile platforms, AMRs, can avoid obstacles or people without stopping. The required safety functions are complex. Particularly when cornering, it must be possible to switch between several protection zones, to ensure that collisions are avoided.

With the new function blocks in the software tool PNOZmulti Configurator of the safe small controller PNOZmulti, synchronization of the axes on an AMR can be monitored reliably. The program function compares the encoder values of the two axes, enabling conclusions to be drawn about the mobile platform’s direction of movement.

With this information, the safe zone switching required can be implemented dynamically in the safety laser scanner PSENscan, the second component in Pilz’s safety solution. This also is made possible by the equally new PSENscan function block in the PNOZmulti Configurator. PSENscan can dynamically switch up to 70 protected fields using the “zone selection function.” At high speed, the protection zones are larger to ensure that obstacles are detected at an early stage. At slower speeds, they can be correspondingly shorter to keep downtime to a minimum.

The configurations created in the PSENscan Configurator can be imported and processed in the navigation computer for the freely navigating platform. The safety laser scanner PSENscan provides the laser beams’ distance data, for localization and navigation of the mobile application. Data transfer is via UDP (User Datagram Protocol) and can be queried via standard, open interfaces via a C++-Library or ROS (Robot Operating System). This gives users flexibility and makes it simple to create maps of the environment for navigation.

As freely navigating platforms, AMRs communicate with their master controller by radio. This

makes them vulnerable to external attack, leading to unauthorized data access or manipulation. Map data could be queried and in the worst-case scenario AMRs could even be shut down. The industrial firewall SecurityBridge protects the network from manipulation and ensures that no unauthorized person can access the mobile platform’s internal IT network during operation.

New Integrated AMR Solutions with Lifter and Roller Modules

heavy goods.

OMRON Automation’s (Hoffman Estates, IL) new medium-payload autonomous mobile robots (AMRs), the MD-650 and the MD-900, are launching as complete solutions with top modules by ROEQ (Vissenbjerg, Denmark), a leader in mobile robotic equipment. Businesses looking to deploy AMRs in their facilities often realize that an AMR without a top module is like a robot arm without a gripper. A lifter top module enables an AMR to drive underneath the cargo, lift it up and transport it to the desired location, while a top roller makes sure that the cargo is seamlessly transferred from the AMR to a conveyor station, providing a fully automated, efficient logistics cycle. “Manufacturers are adopting AMR technology at a staggering rate as the world moves forward from the supply chain crisis inflicted by the pandemic, and it’s never been more important to launch complete, out of the box solutions accelerating production automation projects,” said Kyle Hable, group product manager, OMRON Robotics and Safety Technologies, Inc. The TML500/TML750 Lifter is a versatile flat top lifter solution enabling the MD-series to safely pick up, transport, and drop off pallets and cargo up to 510 kg (1, 120 lbs.) with the MD-650, and 760 kg (1,680 lbs.) with MD-900. A new ROEQ PR750 Pallet Rack is also available with a space saving multi-rack option. An optional ROEQ Cargo Sensor Kit provides additional control to ensure goods stay in place on the AMR. The Lifter is available for both U.S. and Euro pallets.

The TR600/TR700 Roller is a heavy-duty top roller allowing the MD-series to pick up and deliver heavy goods, up to 675 kg (1,490 lbs.) between conveyor stations. The full solution includes the award-winning ROEQ GuardCom system which provides additional safety and efficiency when transferring between the top roller and the receiving station, using robust sensor technology.

Both modules come with ROEQ Assist software for fast and consistent set up and are compliant with safety standards. A ROEQ cart solution, boosting the payload capacity of the MD-series, will be released later this year.