CLEANING IN THE REMANUFACTURING INDUSTRY

Remanufacturing is the rebuilding of a product to OEM specifications using a combination of used, repaired, and new parts.

Posted: April 3, 2024

Remanufacturing is the rebuilding of a product to OEM specifications using a combination of used, repaired, and new parts. Remanufactured parts are required to meet the same customer expectations/performance as new parts. The remanufacturing process encompasses a variety of industry segments, such as Automotive, Aerospace / Aviation, Marine, and Heavy Equipment. Basically, if it has an engine, transmission, or a variety of other parts that can be rebuilt like new, remanufacturing is a great way to preserve the longevity of a product and help preserve the environment. The remanufacturing of parts has many benefits, including reduction of environmental impact, energy conservation, reduction in air pollution, lowering of raw material consumption, and reduction of usage landfill space.

Remanufacturing companies have been “recycling” for more than 80 years. This ever-growing and evolving industry has faced many challenges when it comes to parts cleaning. This is the case, especially for the removal of burned-on carbonaceous soils from both aluminum and steel parts.

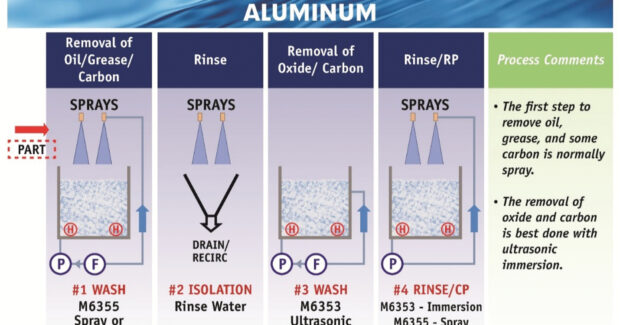

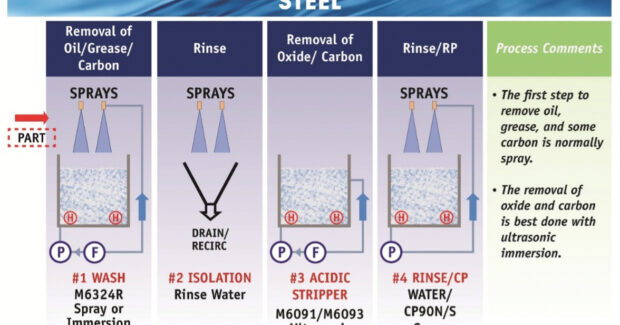

KYZEN has developed aluminum-safe products like METALNOX M6353, M6355, and M6357 to effectively remove carbon and oxide from parts. A cleaning process including these chemistries produces bright aluminum parts, significantly reducing and even sometimes eliminating media blasting. The reduction or elimination of media blasting saves time and labor as well as material and energy costs.

A similar process to aluminum parts cleaning, KYZEN offers products that are specially formulated to address the heavy soils and challenges of remanufactured steel parts in different stages of the cleaning process. KYZEN’s suite of remanufacturing cleaning chemistries offers improved efficiency in the removal of heavy oil/grease, carbon, and oxides. The best process involves the removal of oil, grease, and carbon first, followed by removing oxides. The final step in both cleaning processes, depending on what happens to the parts next, is a compatible Corrosion Protection product.

Do you need help defining and setting up your cleaning operation? KYZEN’s team of process engineers have more than 30 years of experience helping to improve cleaning processes. Answering the needs of engineers in all fields, including military, automotive, and aerospace, KYZEN offers a complete line of parts cleaning chemistries to meet even the most stringent cleaning specifications and requirements. KYZEN products are specifically engineered to be compatible with all materials of construction used in industrial parts cleaning systems and processes, as well as an array of metals and soils.

Global Team of Cleaning Experts Who Care

KYZEN is continuously honored for innovation, quality, and service. Their unique approach connects leading science with care to fully understand your unique process, cleaning needs, and challenges. They do the technical problem-solving for you and usually at no cost.

KYZEN Global headquarters, located in Nashville, TN, USA, has a state-of-the-art Applications Laboratory as well as applications labs and facilities around the world. Their brand is built on a unique commitment to respond quickly, show up anytime, anywhere in the world there is a cleaning problem, and tackle it head-on until it is successfully resolved.

The demands of metal finishing and fabricating are broad and diverse. From cleaning routine parts and applying corrosion protection to meeting demanding Mil-Spec or aerospace requirements, or anywhere in between, find the reliability and performance you need in your cleaning process by working with KYZEN.

KYZEN is offering a Free Parts Cleaning Assessment to help you identify the best option for your manufacturing process. Visit us at PartsCleaningCheck.com call us at 615-988-5982.