Corporate Profile: Mazak Optonics Corp.

Your partner for innovation.

Posted: April 3, 2024

With over 100 years of experience manufacturing machine tool technology and 30 years building laser solutions for the North American market, Mazak’s commitment to innovation is evident through the company’s advanced laser and automation products.

flat sheet lasers

Most recently, Mazak released the innovative OPTIPLEX NEO flat sheet laser-cutting platform which offers proprietary beam shaping technology to deliver optimal thick and thin metal cutting, higher cutting speed, and superior edge quality. The OPTIPLEX NEO platform is available in 4-, 7-, 10-, 15-, and 20kW power options plus 3015 and 4220 machine size options. The machines feature large front and side access doors for increased accessibility when loading/unloading material, and a rotating CNC gives operators the option to work at the front or side of the machine. Intelligent Functions, including Nozzle Changer, Nozzle Centering Camera, and Camera Assisted Part Nesting facilitate optimal laser-cutting performance.

tube and pipe lasers

Mazak’s lineup of tube/pipe lasers include machine options specific for small to medium diameter tube production and large, structural applications. The FT-150 machine option delivers high speed and high productivity for small to medium diameter tube production by streamlining and automating processes through advanced technologies. Mazak’s FG-220/400 machines are optimized for high-accuracy cutting of heavier material with larger diameters and lengths. Their multi-axis capabilities enable cutting a wider range of structural material not possible on 2D configurations.

automation solutions

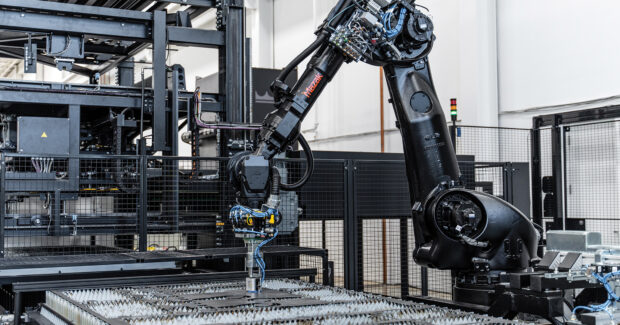

Innovative automation solutions extend the throughput capacity of flat sheet laser machines and provide the ability to flex capacity through lights-out operation, without adding manpower. Most automation solutions are compatible with existing laser equipment to enhance current production processes. Available in various sizes and configurations, Mazak’s automation systems are modular and can be combined to create an optimized solution unique to each production environment.

The new SMART CELL automation solution from Mazak is a 6-axis robot that utilizes interchangeable magnetic and suction cup grippers to sort laser-cut parts, load raw material, and remove remnant material. The sorting system is available in multiple size and payload options to sort a wide range of geometry, with the base design featuring a small 20′ x 20′ footprint. Ideal for first-time automation users, SMART CELL offers an easy-to-use interface making it a great solution for production environments running similar jobs and job shops running multiple parts of different nests. SMART CELL can be integrated as a standalone solution or with automated storage towers for continuous production.

tailored to your needs

There is no one-size-fits-all solution when it comes to laser and automation configurations. Mazak’s team is equipped to address each fabricator’s specific requirements and places a high importance on customer success. Mazak operates with a “Together Success” approach which is best exemplified through the company’s customer service practices. Unlike most laser manufacturers, Mazak offers comprehensive customer care, including lifetime service and parts support on every machine sold. When manufacturers choose Mazak as their Partner for Innovation, they can rest assured that they have partnered with a company that stands by its products.