FABTECH Canada: Vertical Machining Center for Large Parts, Tapping and Drilling Arms

Flex Machine Tools will highlight in two booths a range of machining, drilling and tapping technologies at FABTECH Canada, June 11-13, 2024, at The Toronto Congress Centre.

Posted: April 30, 2024

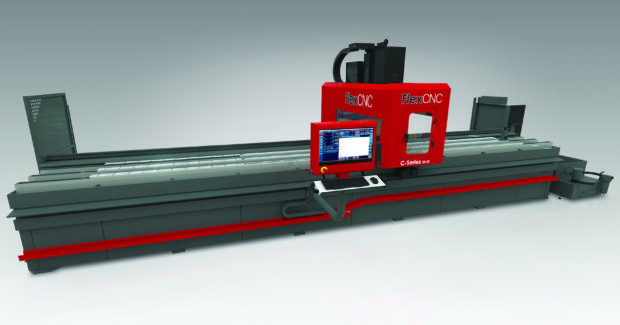

Flex Machine Tools, an American manufacturer and leading provider of machine tool solutions worldwide for metal fabrication operations and more, has announced that it will be highlighting in two booths a range of machining, drilling and tapping technologies at FABTECH Canada, June 11-13, 2024 at The Toronto Congress Centre (South Building) in Toronto, Ontario. Flex will be exhibiting in the Westway Machinery Booth #5019 with a FlexCNC C-20-02 C-Series Vertical Machining Center. Flex will also be demonstrating its FlexArm Tapping and Drilling Arms in the Flex Machine Tools Booth #8026.

The FlexCNC C-20-02 is a versatile, cantilever-style vertical machining center for accurate, high-speed drilling, milling and tapping of large parts. The machine accommodates a range of part sizes from 10′ to 50′ long, and part volumes ranging from a single-piece to high-volume production. A monobloc welded steel frame with precision linear guideways provides a strong, rigid infrastructure which works in tandem with a comprehensive motion control system, making the FlexCNC C-20-02 ideal for an extensive range of applications. Live machining demonstrations in Booth #5019 at FABTECH Canada will include using a single tool for drilling and threading a steel tube. Also, a continuous drilling operation on a 6′ round tube with tail stock will be shown. In addition, a probe application will highlight locating the center line for drilling.

In Booth #8026, Flex will be demonstrating its fast, reliable and flexible FlexArm REM-24D Electronic Tapping Arm with a Multi-Position Head that allows quick and easy switches between vertical and horizontal tapping. The REM-24D Tapping Arm has a maximum reach of up to 70″ (1,778 mm) and is designed to handle taps up to 7/8″ (22 mm).

The FlexArm Mag Drill Arm will also be demonstrated in Booth #8026, highlighting how magnetic drilling can be simplified, while reducing operator fatigue and increasing safety and efficiency. The ergonomic Mag Drill Arm offsets the drill’s weight by effectively reducing up to 75 lbs. (34 kg) of strain on an operator’s body. The Arm provides a working range of up to 100″ (2,540 mm) of horizontal reach and 52″ (1,320 mm) of vertical stroke, resulting in precision and versatility across a broad range of drilling operations.

For more information, visit flexmachinetools.com.