HASTINGS AIR ENERGY CONTROL’S SOLUTIONS REDUCE ENERGY CONSUMPTION

Hastings Air Energy Control Inc., New Berlin, Wis., is well positioned to meet the needs and challenges of the modern metalworking industry for both the short and long term.

Posted: April 3, 2024

Hastings Air Energy Control Inc., New Berlin, Wis., is well positioned to meet the needs and challenges of the modern metalworking industry for both the short and long term. The company constantly improves and develops new automated solutions to assist the industry in overcoming labor challenges and meeting corporate sustainability goals, while lowering energy costs in their facilities.

The majority of a manufacturing facility’s energy is expended in the use of fans and motors to run dust collection equipment. “Through the use of sensors, controls and automation, manufacturers can reduce energy consumption by about 50%-to-80% using new technology,” said David Bohrer, president, Hastings Air Energy Control. “Our best product representing total building dust collection automation is the IVEC Command.”

Using IVEC Command companies experience these features regarding air cleaning and filtration: remote monitoring/access/control; data logging; predictive metrics; self-diagnostic systems; data security; automated reports and notifications; reduced maintenance costs; reduced downtime and lowered energy costs.

“Customers are working on green initiatives and sustainability and constantly looking to reduce energy costs,” Bohrer said. “IVEC Command benefits them through being able to measure energy savings and efficiency during the manufacturing process and allows them to enjoy available grants and tax benefits from the application of our products. Customers using IVEC Command have implemented it on top of their air filtration equipment.” IVEC Command can be used with existing hardware in a retrofit scenario or with a completely new system. The benefits are immediately noticeable and result in year-over-year energy savings with an average ROI of one-to-four years.

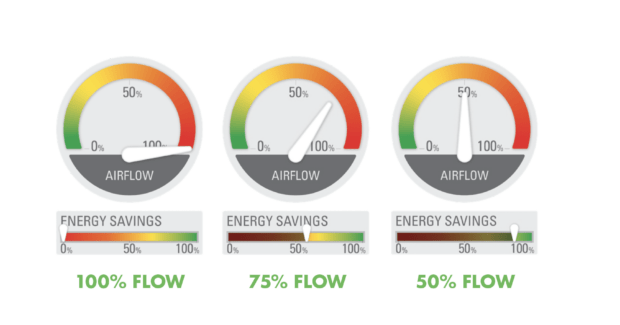

When it comes to solutions for automation and air energy controls, IVEC Systems consists of a full line of automation controls that are designed to manage process control ventilation, Bohrer noted. Static dust collection systems use fans that run at full power during one, two or three shifts. IVEC Controls provide on-demand management of the system much like a home thermostat manages indoor temperature. Using IVEC Controls, the system ramps up or down as needed and completely shuts down portions of the system that may not be in use. IVEC air management results in having just enough power where it is needed without wasting energy.

Helping Companies Achieve Green Initiatives

The solutions and services provided by Hastings Air Energy Control help their customers meet not only their sustainability goals and maintain healthy shop environments, but also provide answers to challenges.

“A military contractor used our IVEC Command system along with ambient air cleaners to clean weld fumes,” Bohrer said. “The company was able to track the overall air flow in the building guaranteeing 70% reduction in welding fumes by capturing, filtering, and returning clean air back into the facility. This was a state-regulated mandate by the local government which requires that weld fume cannot escape to the outdoors and cannot contaminate outdoor air.” The IVEC Command software was used to track and record energy savings. Reports showed that 1.94M kWh were saved, which is a $166,940 annual energy savings. In addition, the new systems earned the company $1,074,771 in energy incentives.

Hastings Air Energy Control continues to advance process filtration/ventilation systems, air filters, and energy-saving ventilation controls, all to the benefit of the metalworking industry. “Article after article points to the need for more remote-access controls for the modern manufacturing facility and Hastings is well-positioned to meet this need given that our IVEC Systems controls were introduced in 2007,” Bohrer said.