Streamlining Automation: Seamlessly Integrate Robot Automation in Your Manufacturing Environment

Caron Engineering’s MiConnect Technology combats the challenges of integrating robot arms into your operations, including CNC and automation device compatibility, limitations for complexity and more.

Posted: April 29, 2024

Machine tending is crucial for realizing complete automation in manufacturing production. Effectively incorporating machine tending to align with CNC and other automation systems serves as a strategic approach to automate processes and improve overall efficiency. While the fundamental functions of robot control, safety prioritization, and proper functioning are covered by robot brands’ programming software, extending communication beyond the immediate cell poses significant challenges. Many existing solutions lack the capabilities required for connecting with other devices, databases, or interacting with supervisory systems. Additionally, limitations in control parameters and adaptability to changing processes often hinder the full potential of machine tending integration.

Caron Engineering’s MiConnect Technology combats the many challenges of integrating robot arms into your operations, including CNC and automation device compatibility, limitations for complexity, and flexibility and adaptability to changing processes.

MiConnect is a customizable application builder tailored for manufacturing, enabling the seamless connection and control of all devices in your manufacturing environment. Within the MiConnect “toolbox,” you’ll find an inventory of pre-built manufacturing devices including the ability to communicate to CNC controls, robot arms, electronic measurement devices, barcode readers, files, databases, supervisory systems, and much more.

For machine tending integration, MiConnect serves as a software-centric solution. It facilitates the connection of your robot arm with various CNC or automation devices to interact with each other by using the drag-and-drop building blocks of operations to customize your manufacturing process. For example, when a robot unloads a part from a machine, and presents it to an electronic gauge for measurement, MiConnect can signal the gauge to begin the measurement process. Upon completion, MiConnect will signal the robot to unload the part and then will send the data upstream for automated tool wear compensation back to the CNC control.

Robots lack compatibility and device communication. Not all robot arms and automation can connect to all controls. Specific communications protocols are required per control which limits compatibility. MiConnect can create any robot as a device and any CNC as a device to pull in all the registers associated with the control to be used within the platform. This allows for a seamless integration between the robot arm and the control. The user can then use the platform to program the robot arm and control it from a single interface. MiConnect can also be used to connect older machines that have no industrial protocols.

Robots lack the ability to read databases. When a robot is tasked with loading a job into a machine, there are databases linked to that specific job, such as the part program for cutting or the CMM measuring device program for identifying the required feature measurements. The robot is unable to interpret this data. Moreover, if the database needs to be transmitted upstream to a production monitoring system, the robot faces challenges in connecting or communicating with such a system. However, MiConnect Technology simplifies this process, allowing for seamless communication and connectivity.

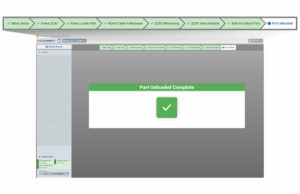

MiConnect streamlines user interaction by providing a singular, user-friendly interface for programming all device communication. The MiConnect HMI displays each step in the process and is customized to display any user defined steps and instructions for the operator to complete before the process advances. Additionally, MiConnect ensures process integrity by systematically logging all interactions. It has the capability to retrieve necessary data from files or databases and transmit data upstream to supervisory systems, enabling comprehensive integration for total production monitoring.

Processes change. The MiConnect platform was created with flexibility and adaptability to ever-changing processes in mind. This empowers manufacturers to create a more versatile and responsive production environment. Before the introduction of MiConnect, manufacturers had to either develop their custom software or seek third-party applications to integrate machine tending functionalities with external systems. This adaptability is essential, particularly when robots require interaction within the broader manufacturing environment or with other interconnected systems.

By providing a solution for robots to communicate beyond their immediate environment or cell, MiConnect contributes to the efficiency and adaptability of robotic systems within manufacturing processes. It offers a more user-friendly and standardized approach to robot integration, reducing the burden on manufacturers to develop custom solutions for each combination of robot arms and control systems. By creating a standardized communication platform, MiConnect enables easy integration between robot arms and all other device communication in your process.

As industries continue to embrace the era of automation, the role of machine tending cannot be overstated. Caron Engineering’s MiConnect Technology serves as a catalyst for overcoming the challenges associated with machine tending integration, offering a comprehensive software-centric solution. By ensuring compatibility, flexibility, and a streamlined integration process, MiConnect empowers manufacturers to unlock the full potential of their automated production systems, marking a significant step towards the future of manufacturing efficiency.